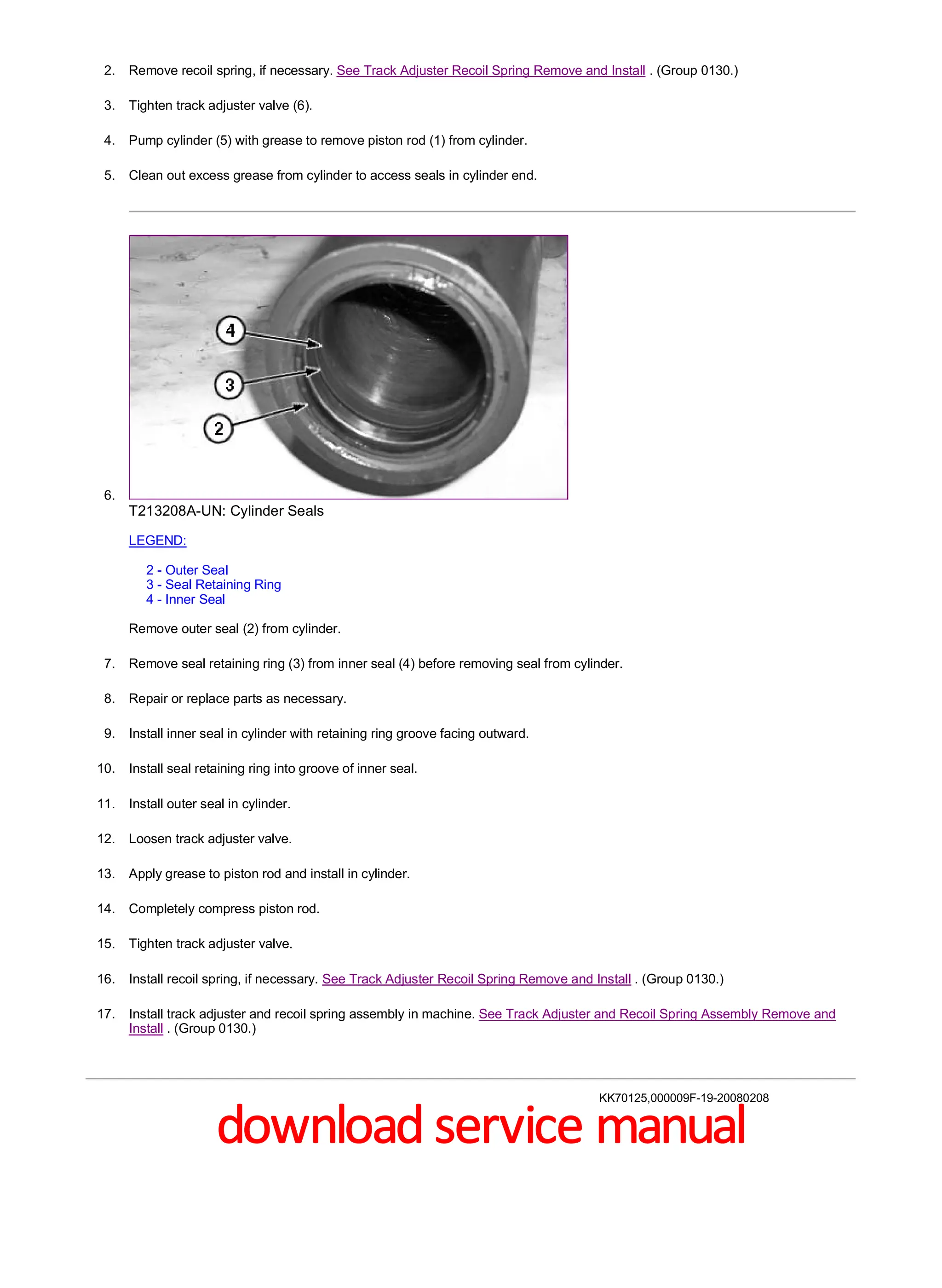

John Deere CT322 Compact Track Loader Service Repair Manual (TM2152).pdf, Complete engine oil system repair manual. Covers the oil pump, oil cooler, and filter base with detailed procedures, torque values, sealing methods, and vital safety precautions. Need to service your engine oil pump? Our manual provides a comprehensive breakdown with assembly diagrams, part references, and torque specs for correct installation and peak performance.