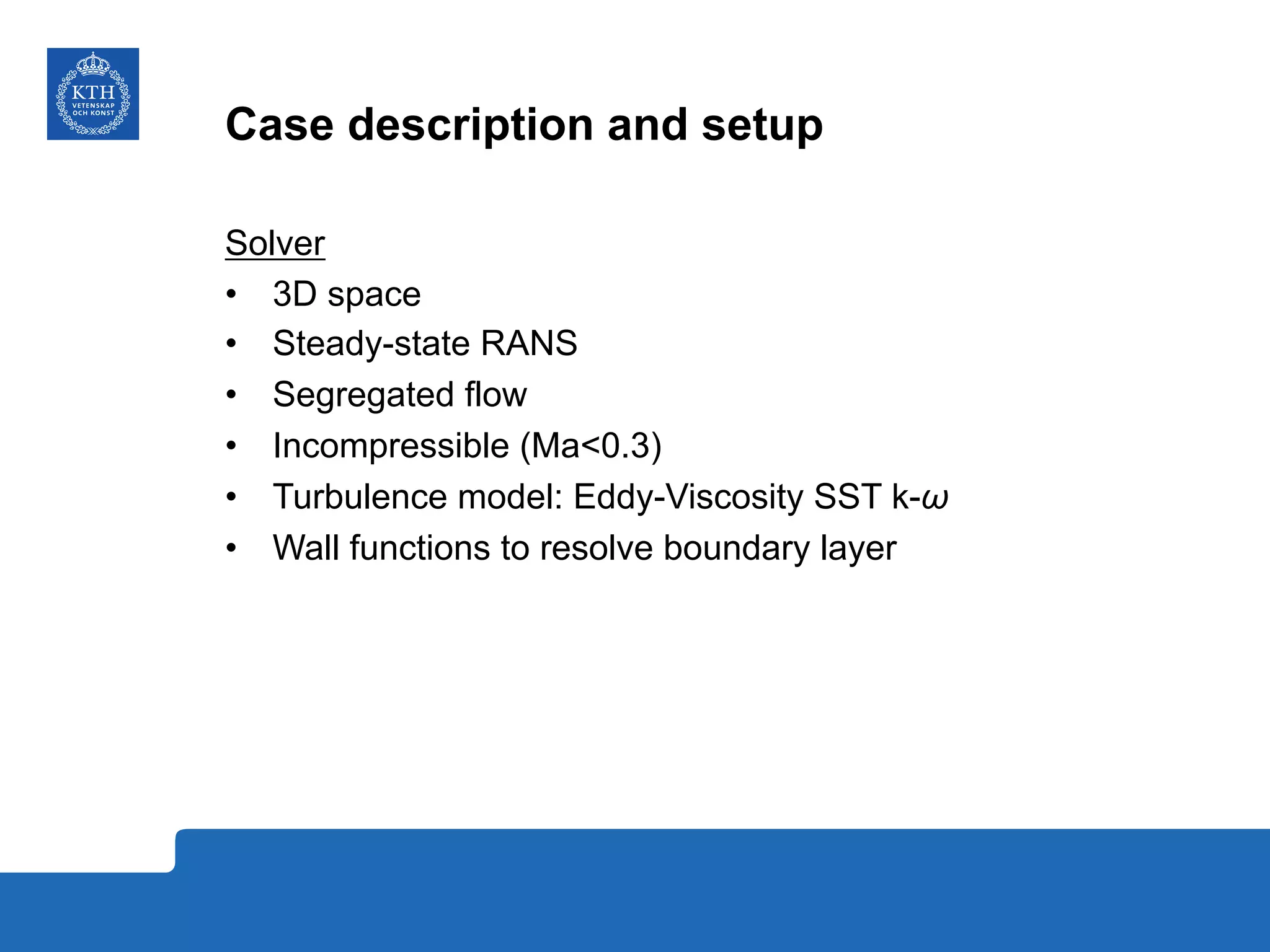

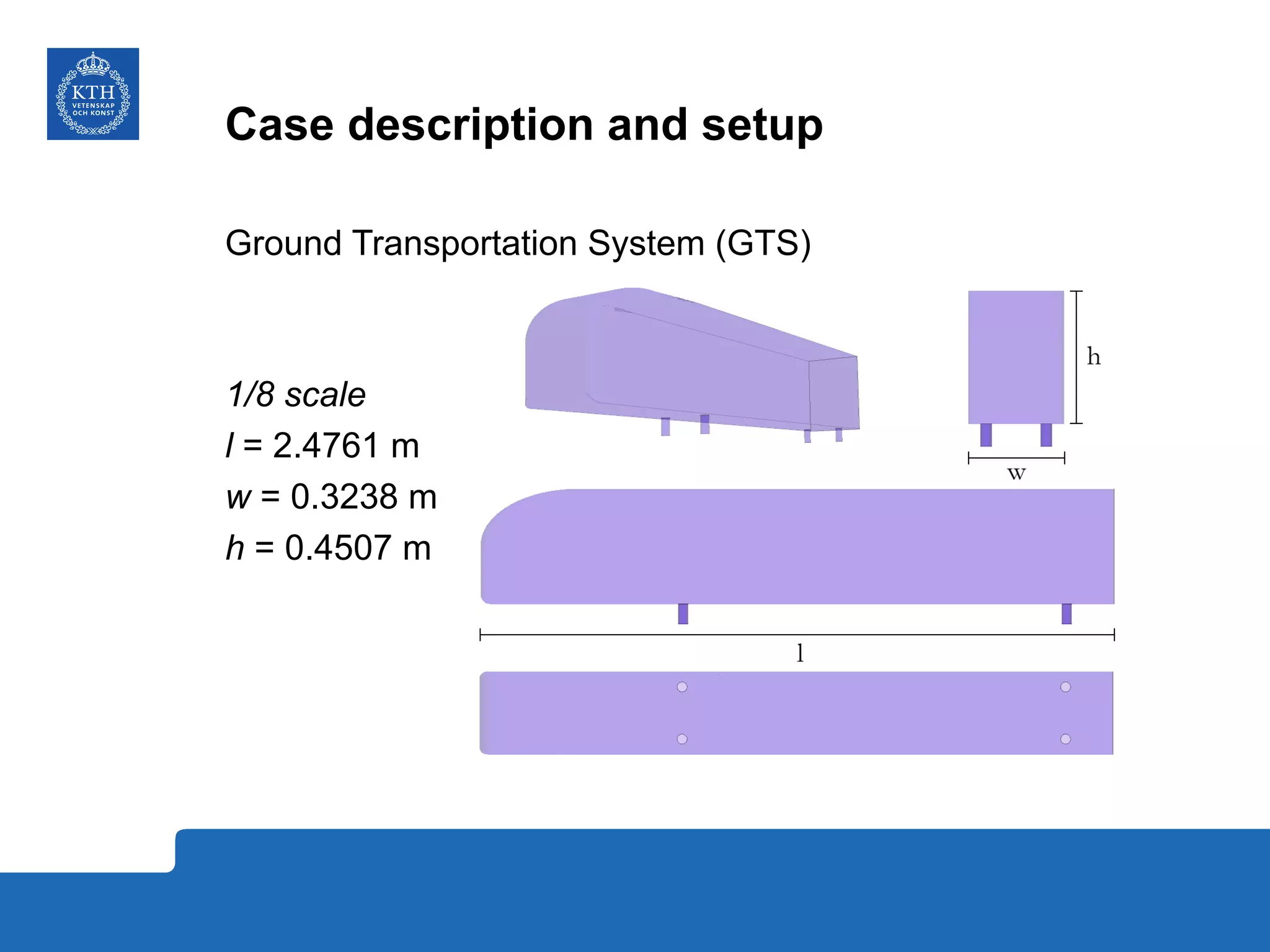

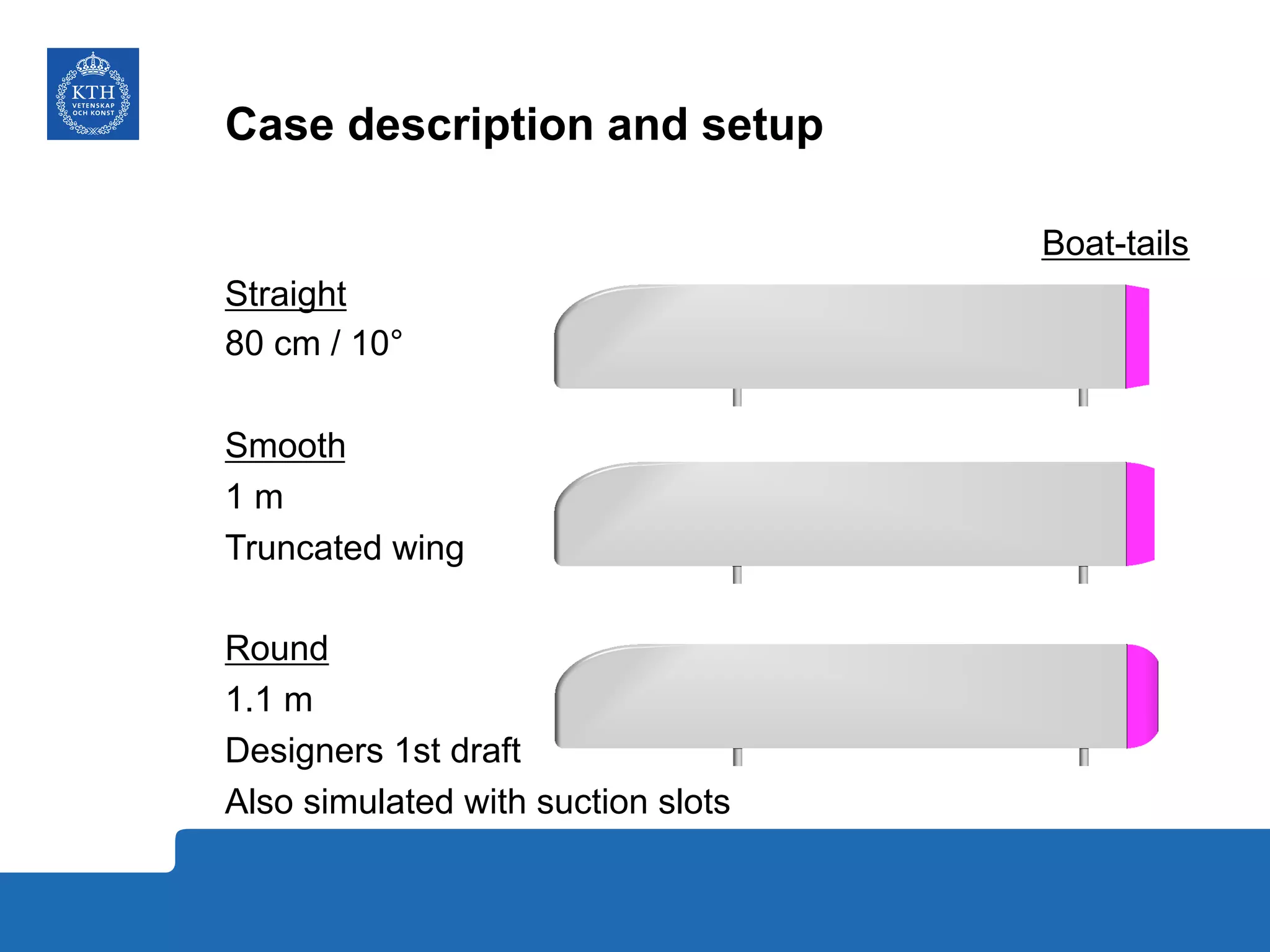

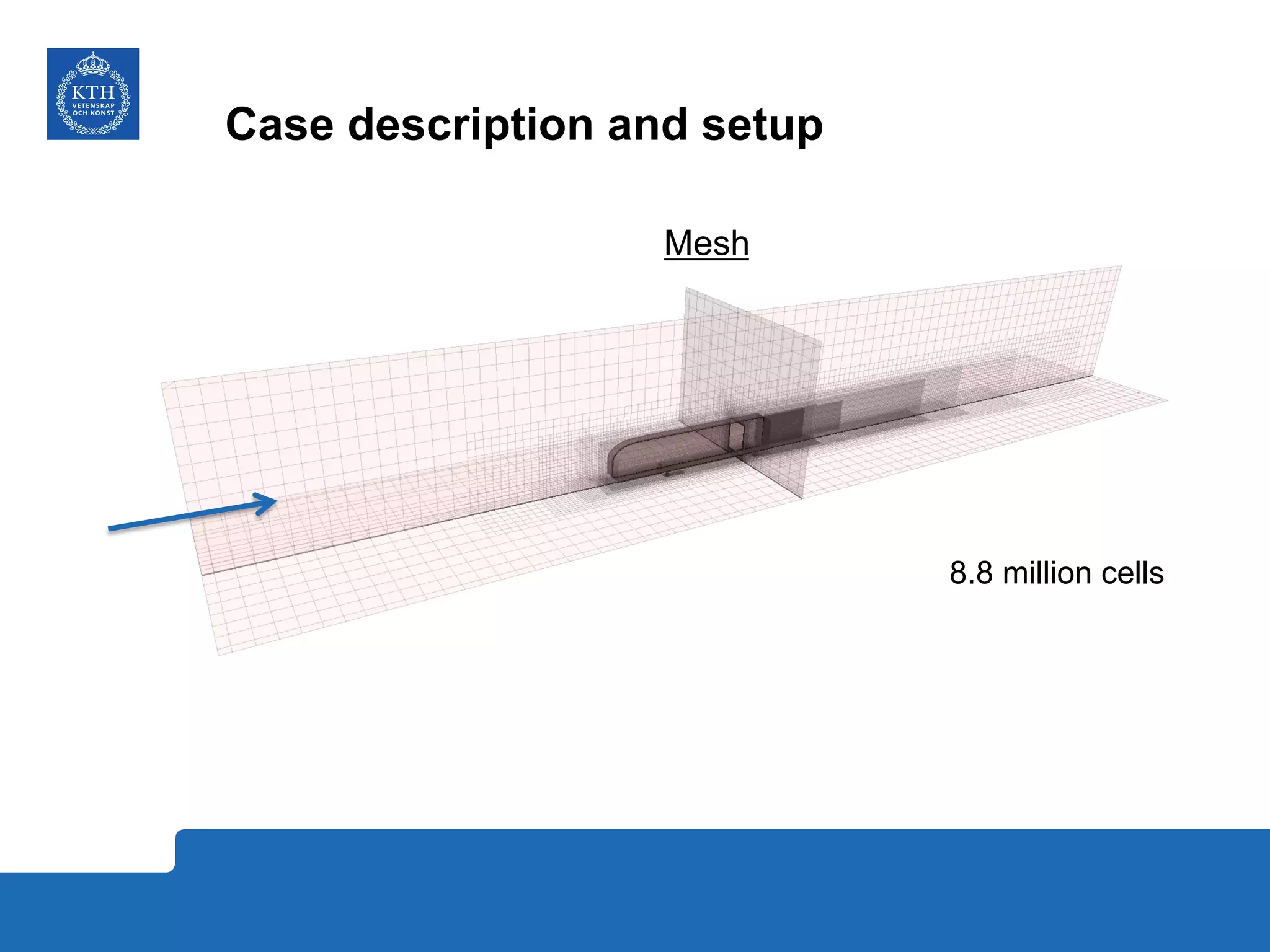

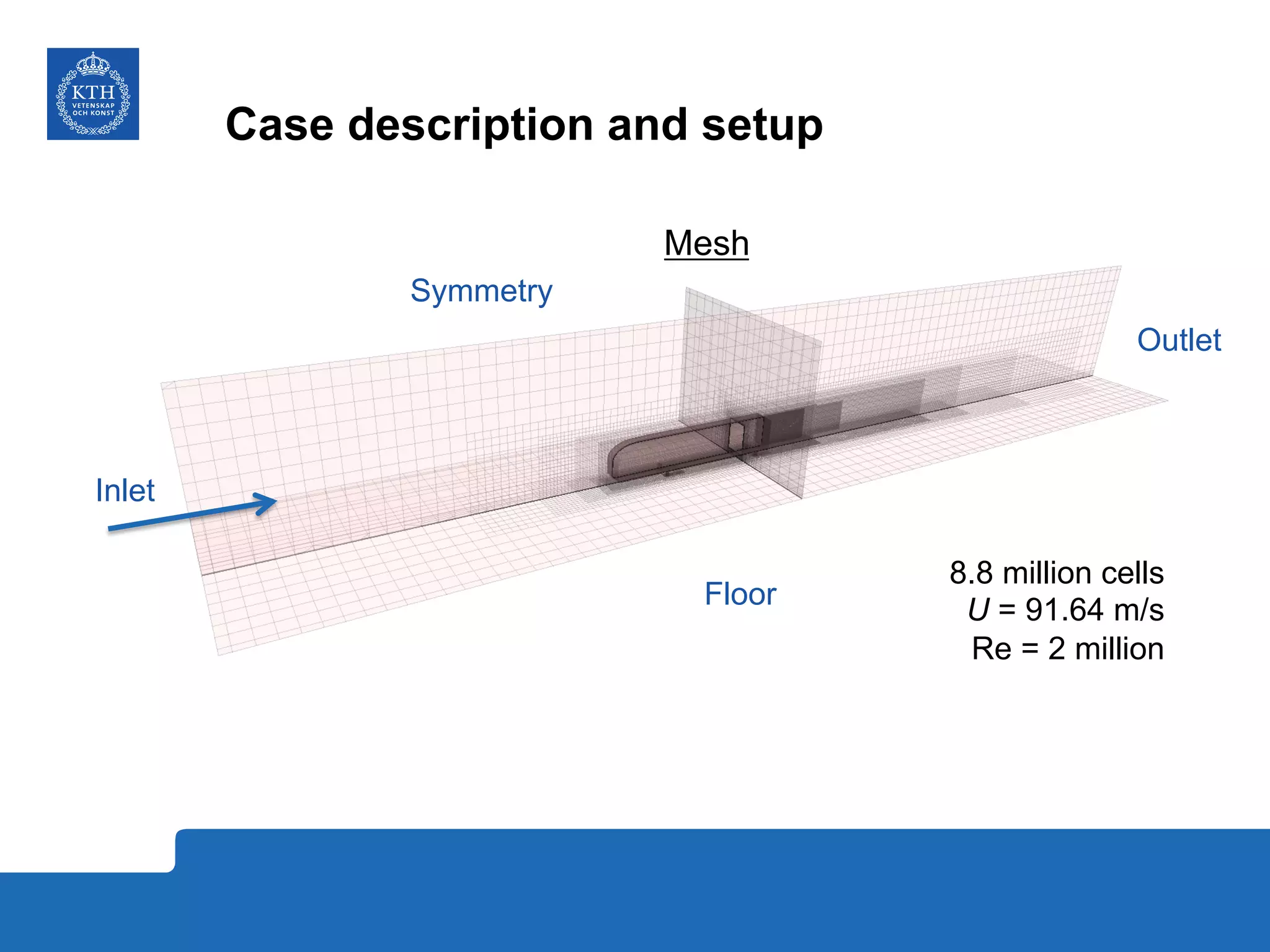

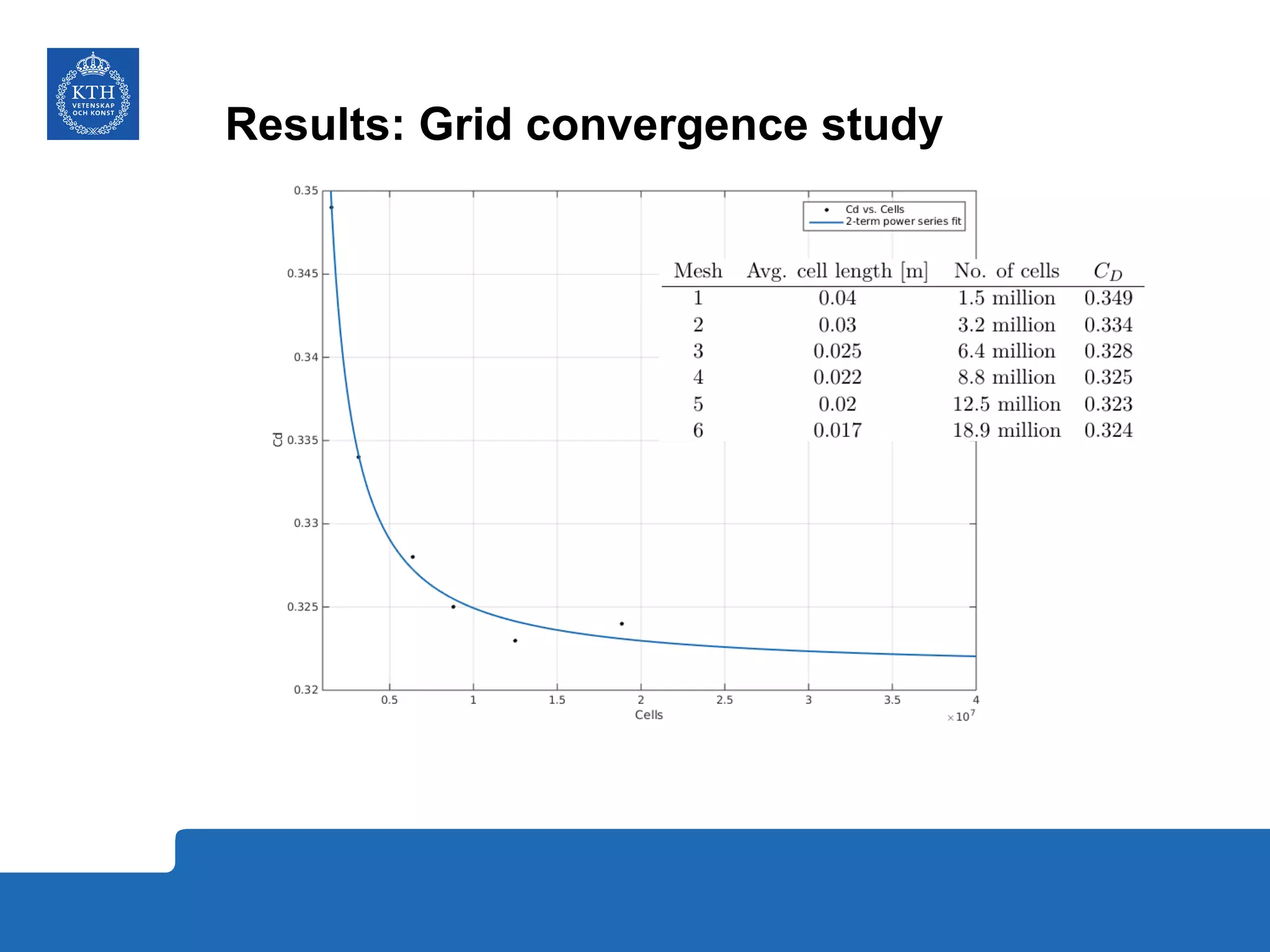

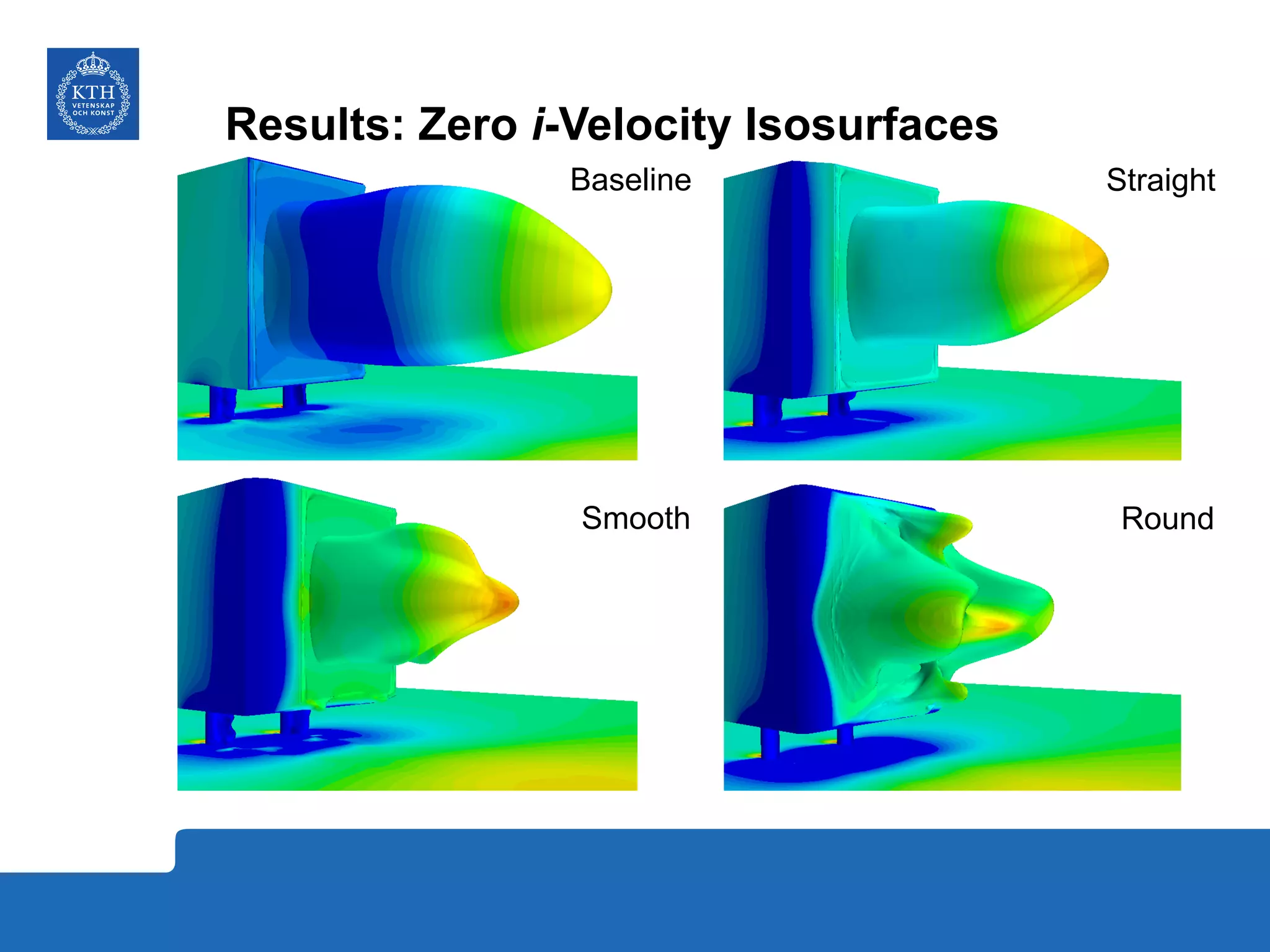

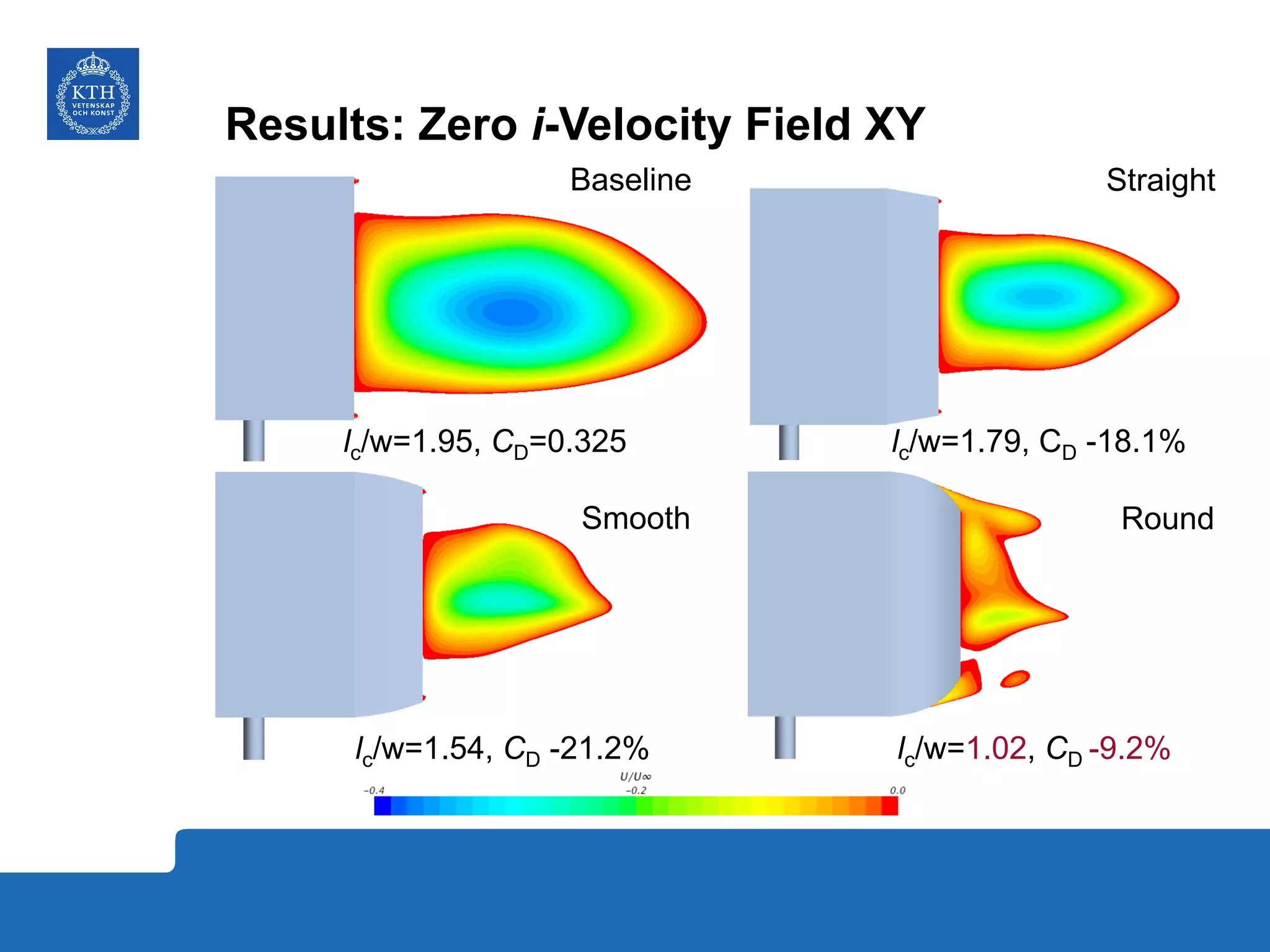

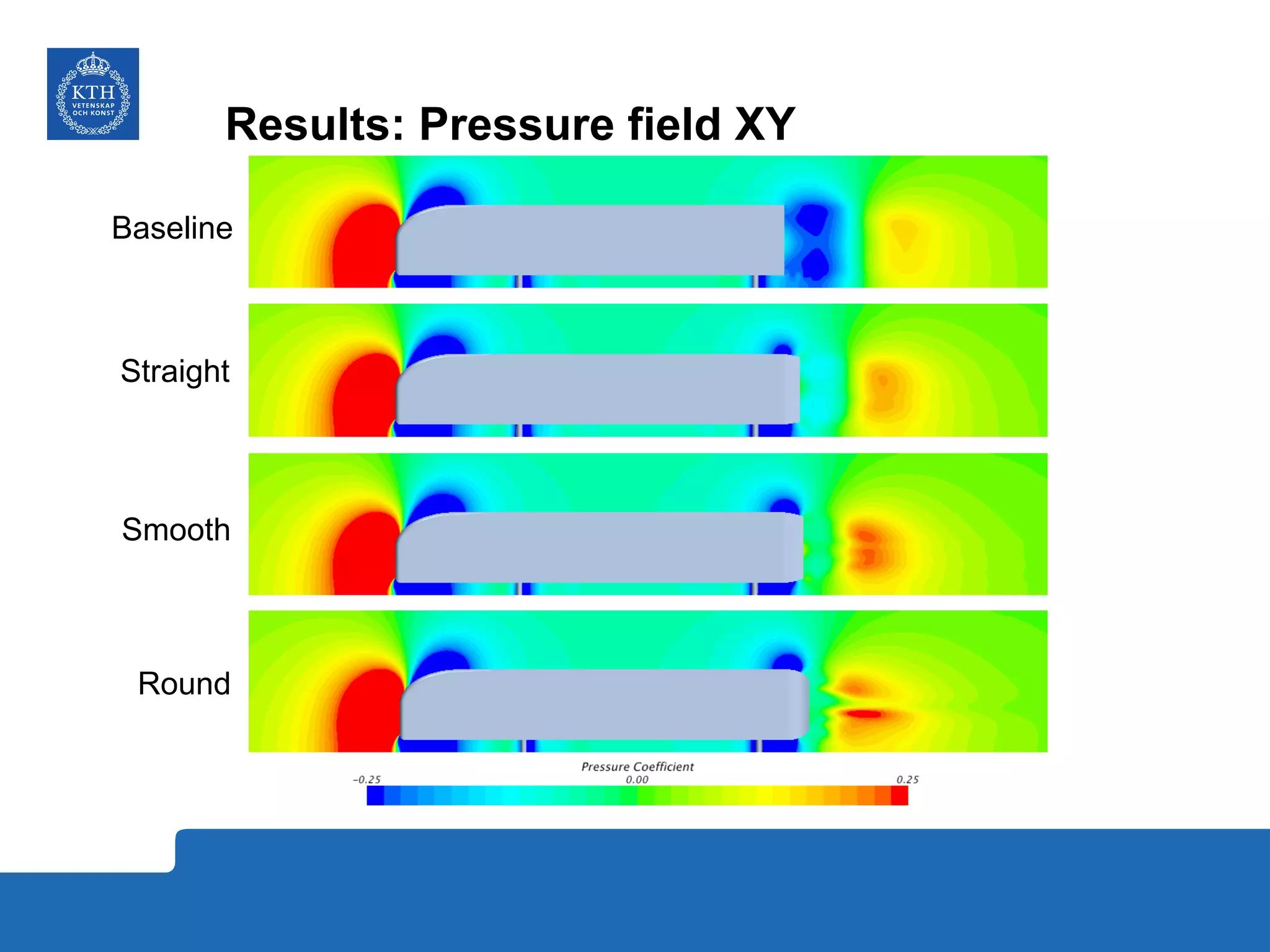

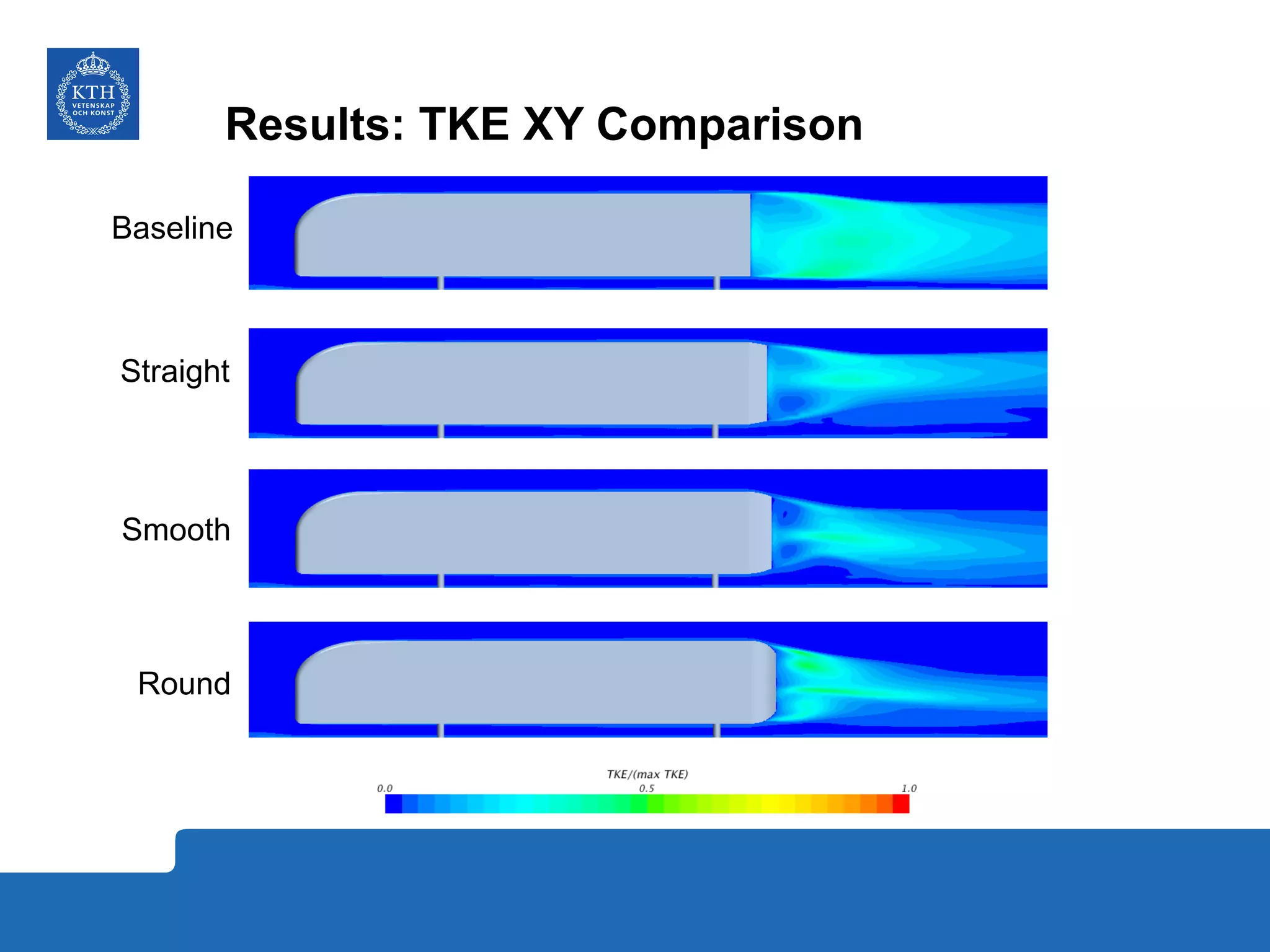

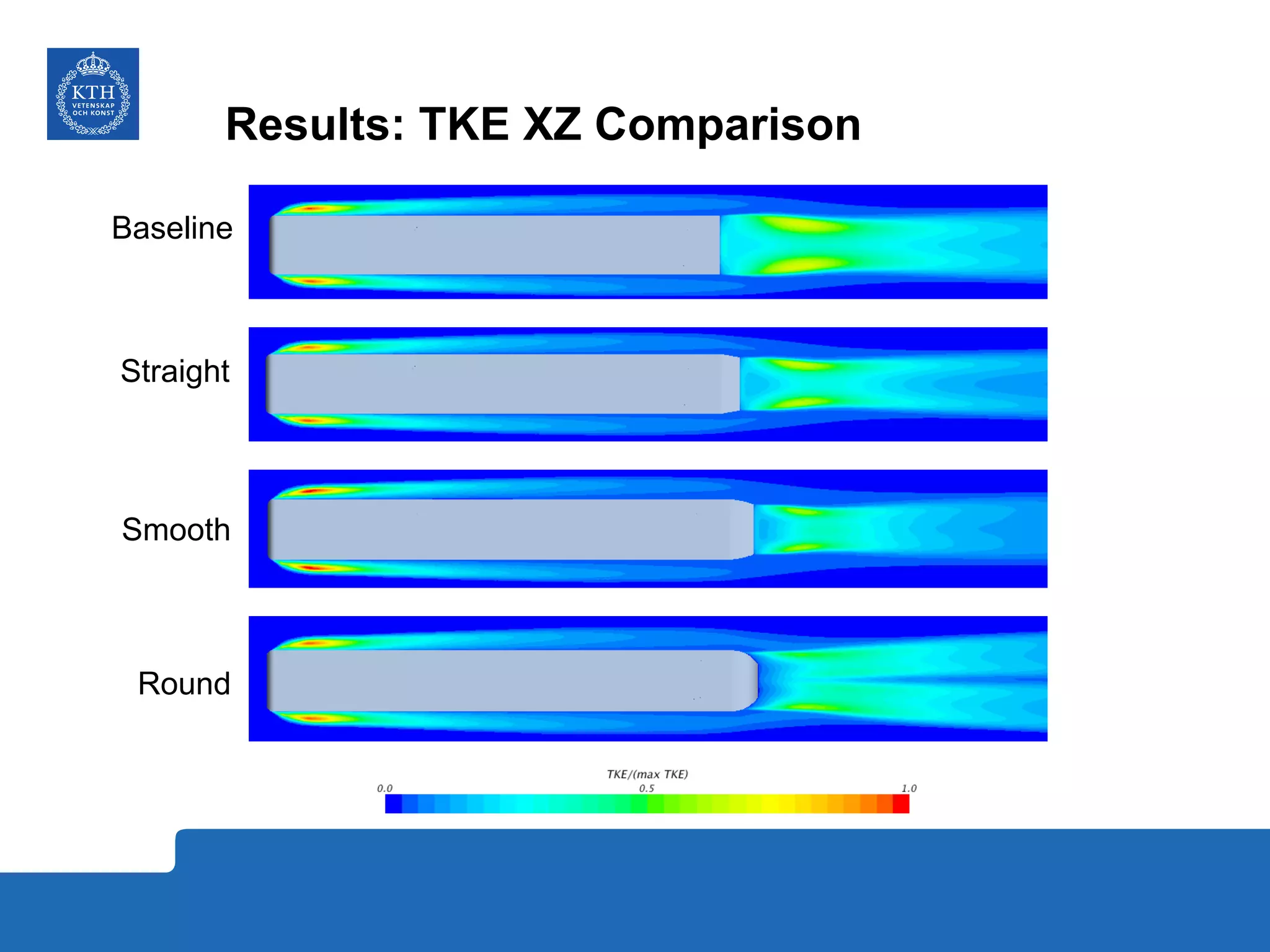

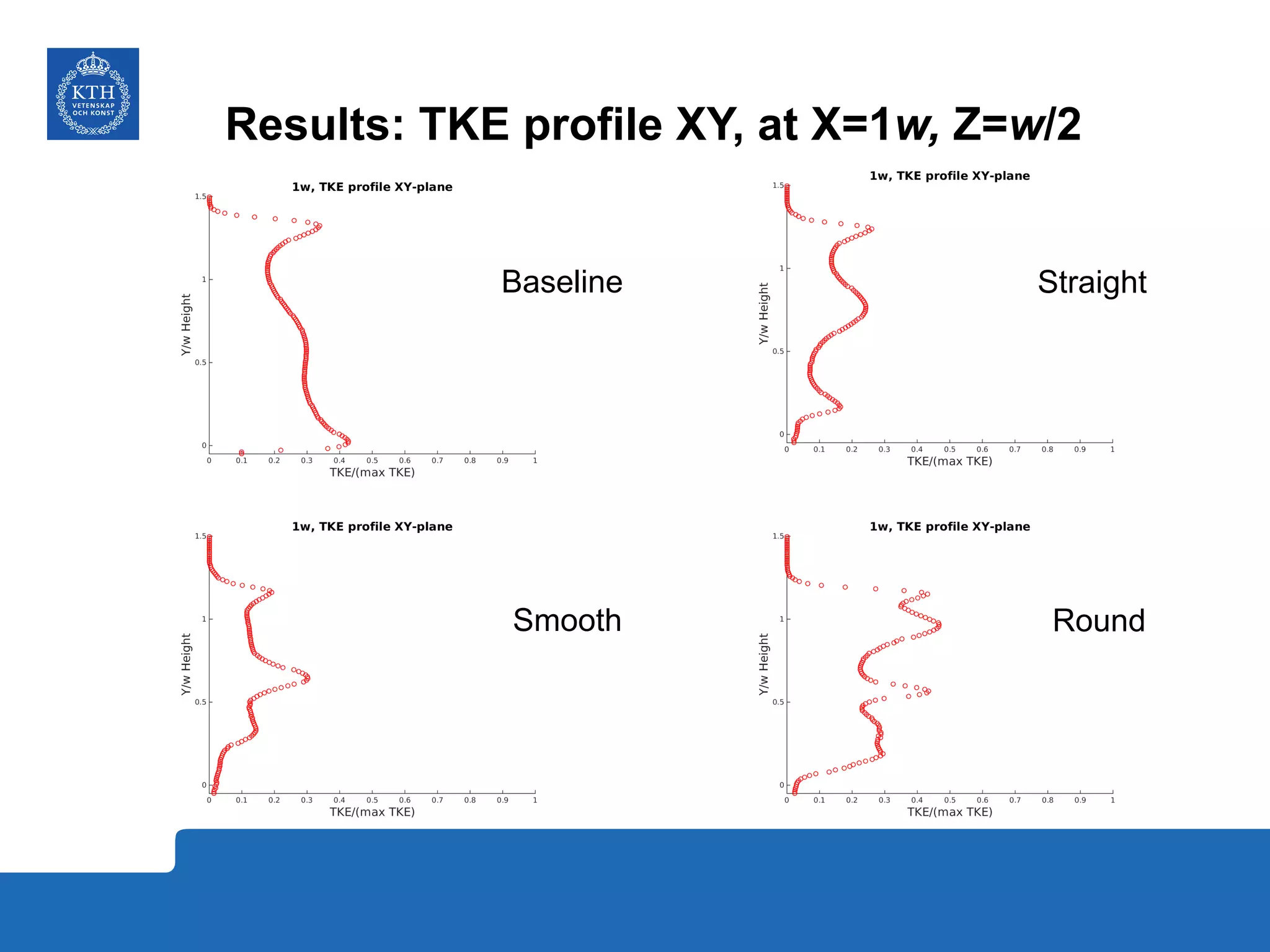

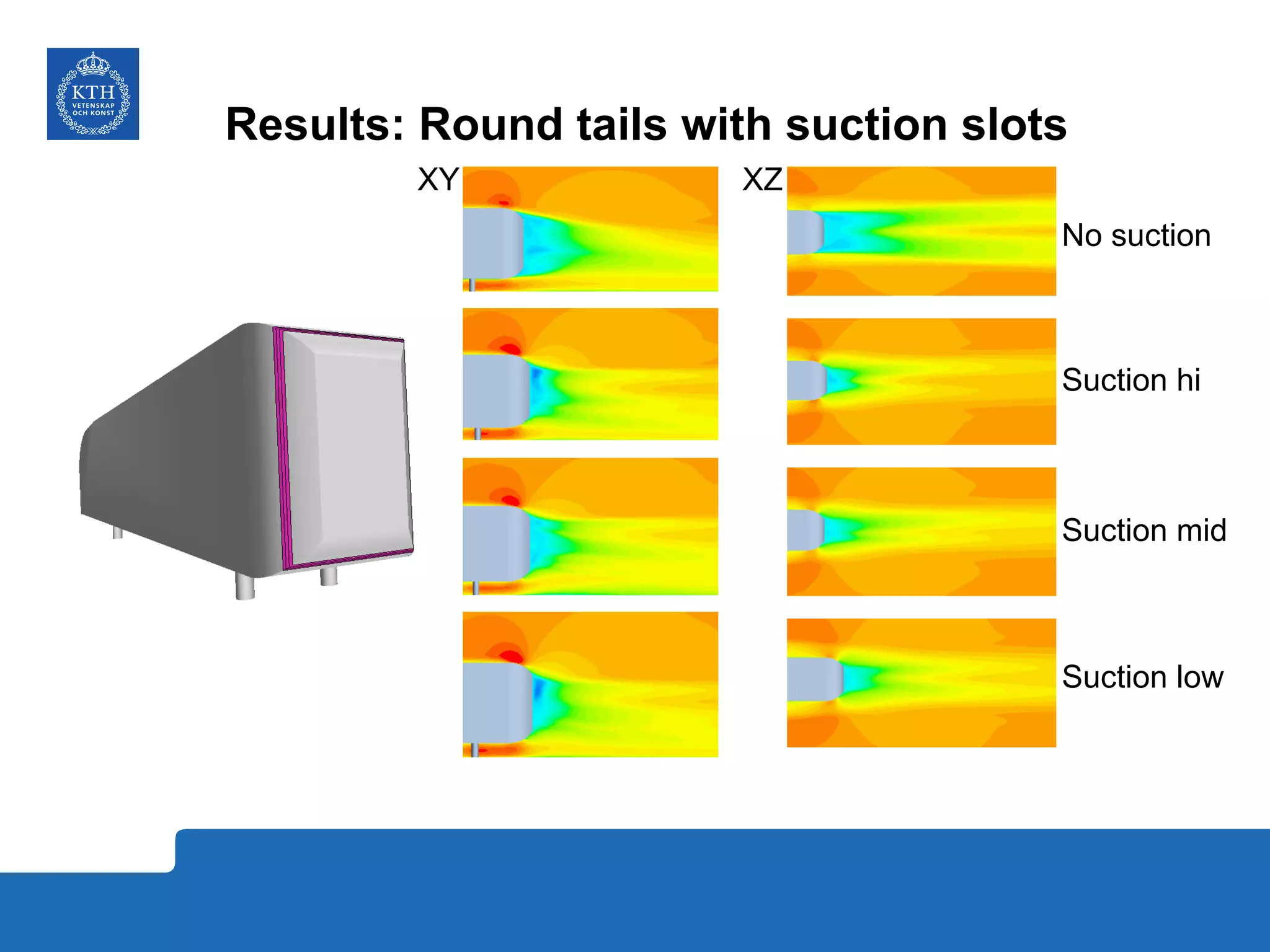

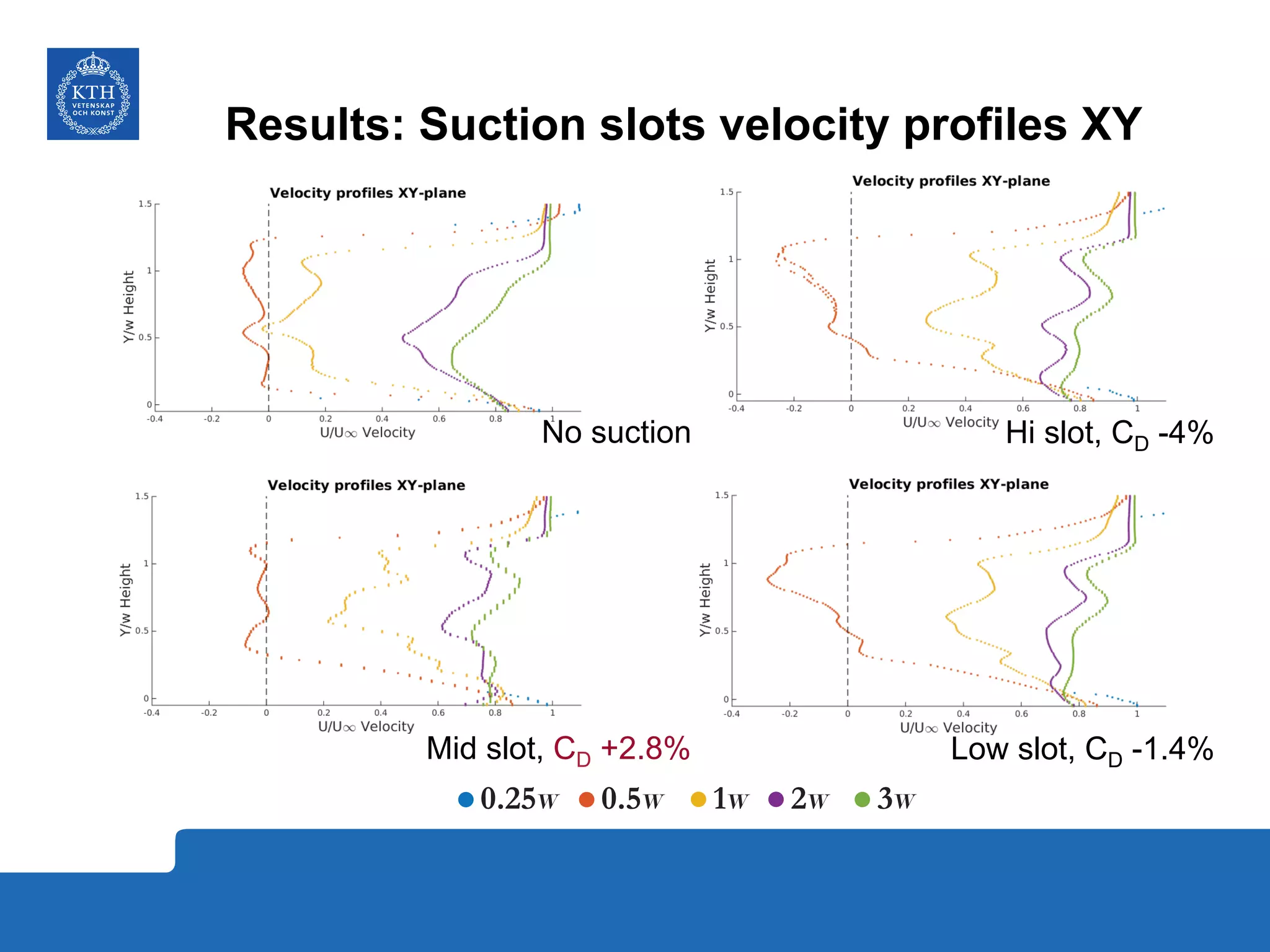

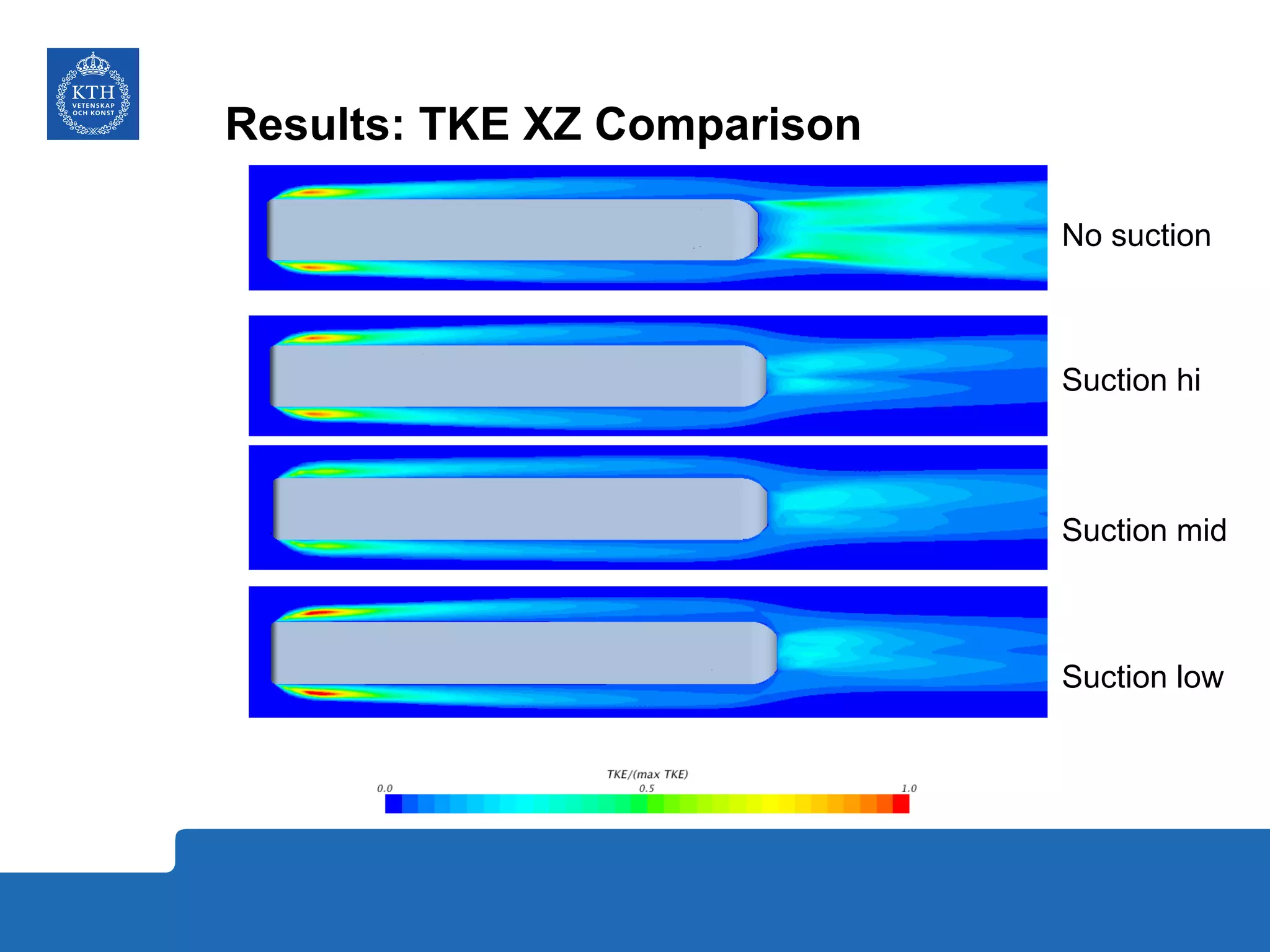

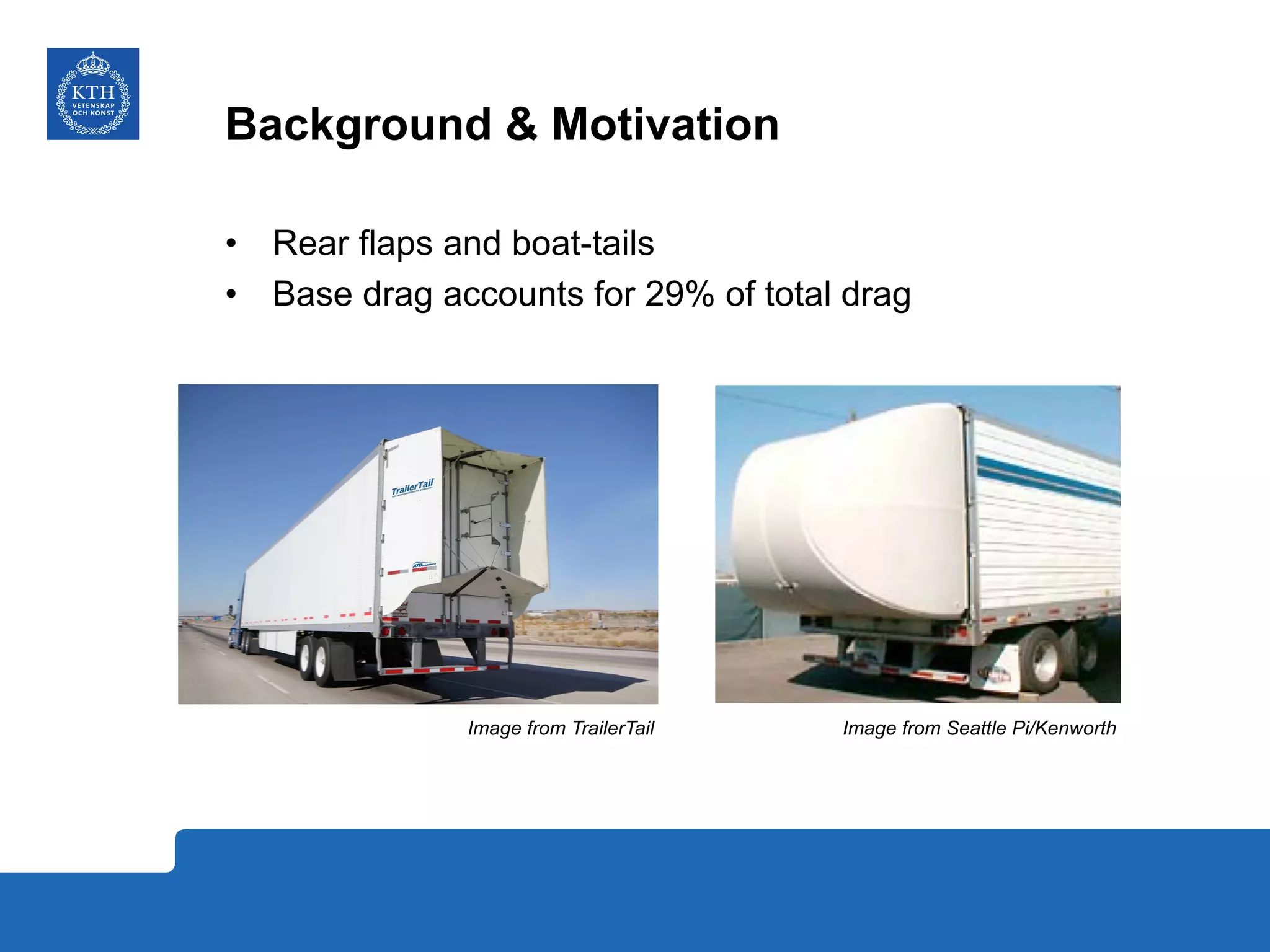

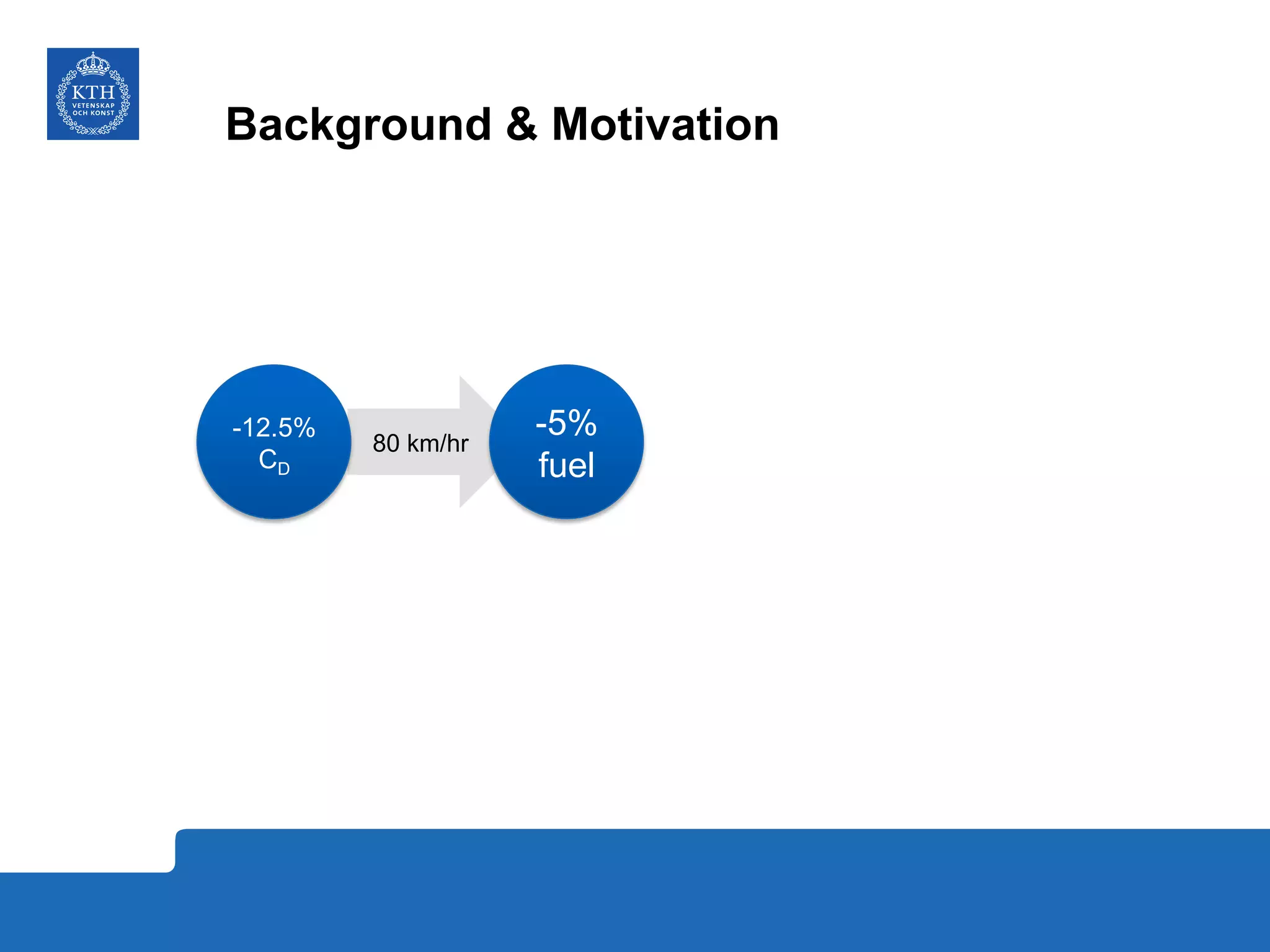

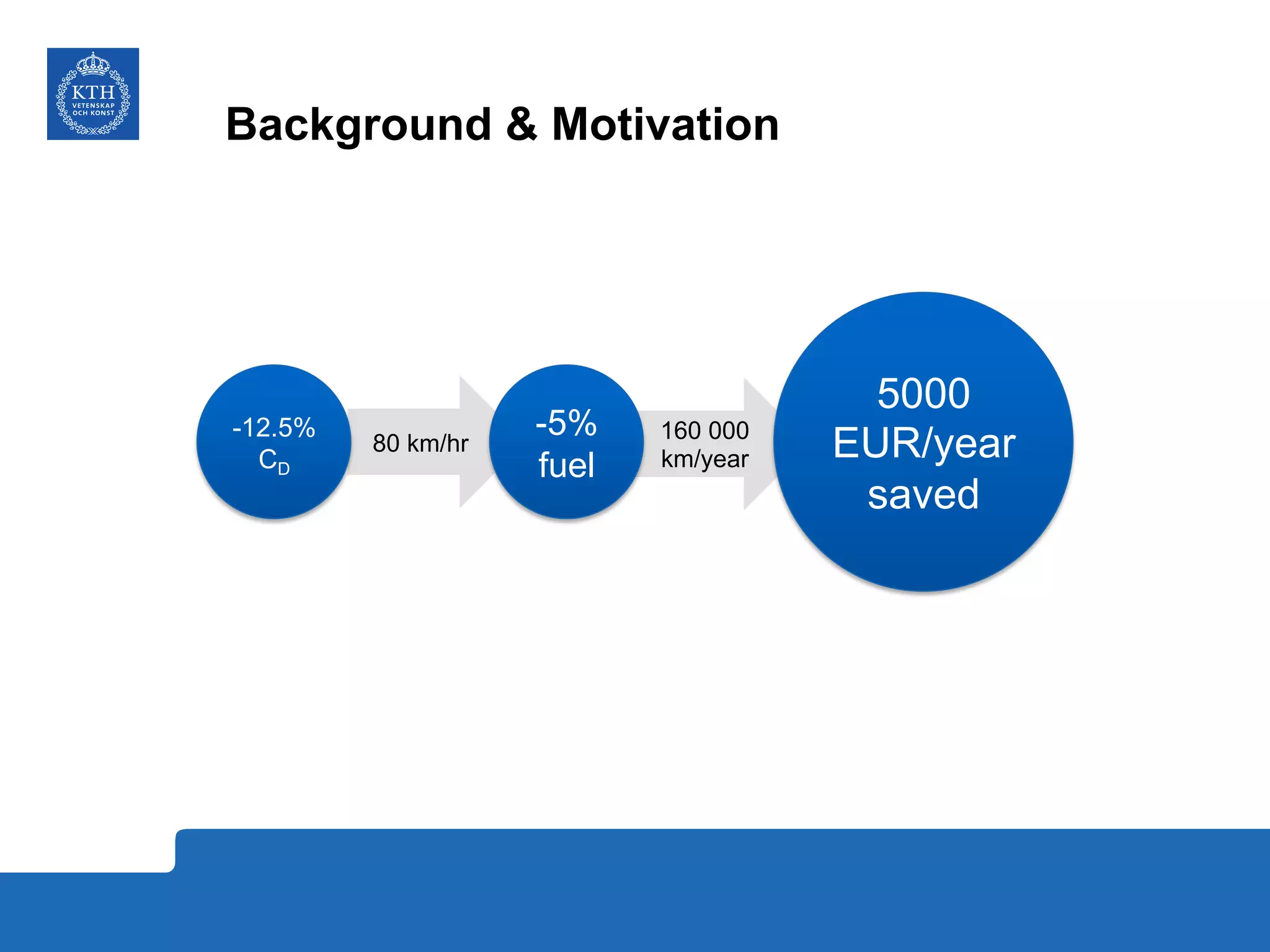

The document summarizes a numerical analysis of improving the aerodynamic performance of trucks through modifications to the design of the rear section. The analysis used computational fluid dynamics to simulate different boat-tail and rear flap designs. The best design was found to reduce drag by 21.2% compared to the baseline design. Further work is recommended to better capture unsteady effects and optimize designs for real trucks.

![Forces, coefficients & representative scales

CD =

2FD

ρU2

A

Coefficent of drag

FD = drag force [N]

ρ = fluid density [kg/m3]

U = freestream velocity [m/s]

A = projected area [m2]](https://image.slidesharecdn.com/f9dcf613-599b-498d-8736-e14baf05cb91-150608162410-lva1-app6892/75/johan_malmberg_thesis_pres_final-15-2048.jpg)

![Forces, coefficients & representative scales

CD =

2FD

ρU2

A

Coefficent of drag

FD = drag force [N]

ρ = fluid density [kg/m3]

U = freestream velocity [m/s]

A = projected area [m2]

Re =

ρUL

µ

Reynolds number

L = characteristic length [m]

µ = dynamic viscosity [PaŸs]](https://image.slidesharecdn.com/f9dcf613-599b-498d-8736-e14baf05cb91-150608162410-lva1-app6892/75/johan_malmberg_thesis_pres_final-16-2048.jpg)