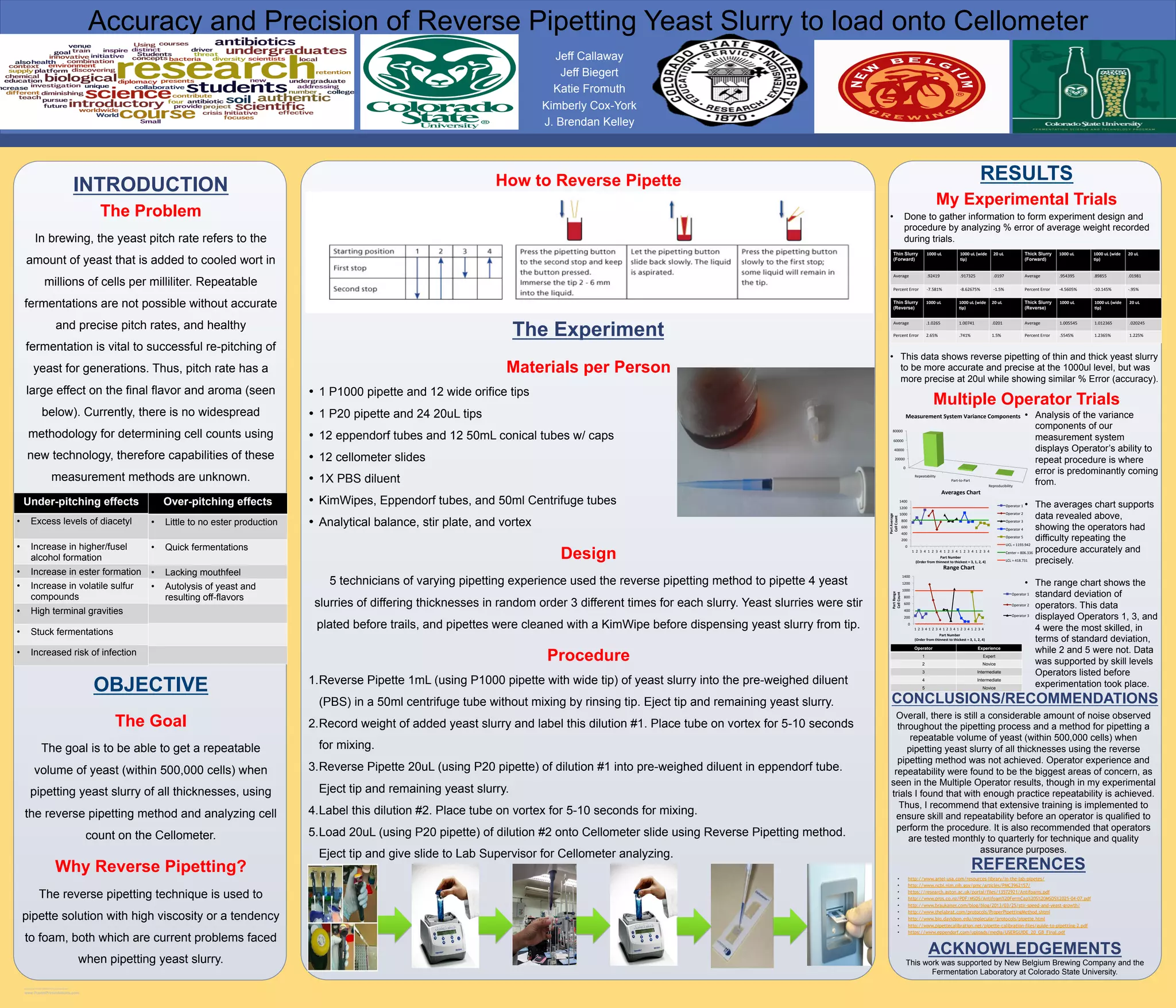

The document describes a study that aimed to determine if the reverse pipetting method could be used to consistently pipette yeast slurry of varying thicknesses and obtain repeatable cell counts. Five technicians with different experience levels used reverse pipetting to dispense yeast slurries, which were then analyzed on a Cellometer. The results showed high variability between operators, indicating a lack of consistency and precision in the pipetting technique. While reverse pipetting yielded reasonably accurate results for an expert pipetter in trials, the multiple operator study demonstrated repeatability was not achieved. The conclusion was that extensive training is needed for operators to reliably perform the reverse pipetting procedure.