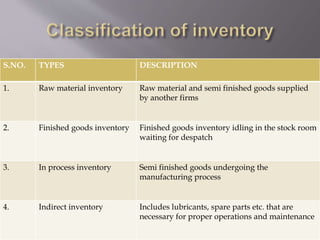

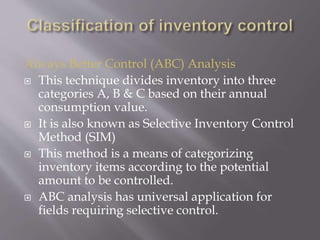

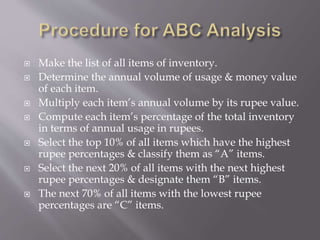

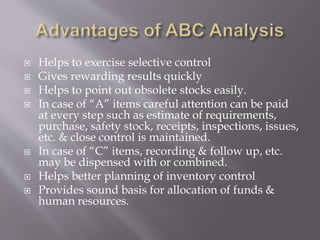

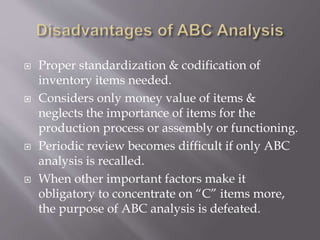

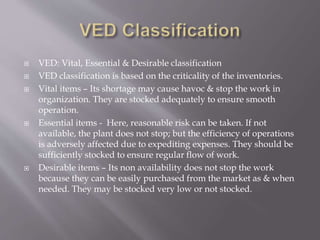

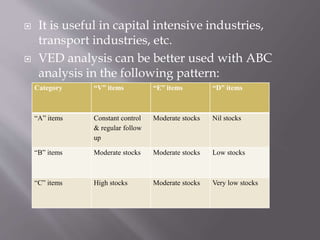

Inventory control is a technique used by organizations to maintain desired inventory levels. It involves recording all materials, parts, supplies, work-in-process, and finished products and keeping them in stock for a period of time. The goal is to balance inventory levels in a way that best serves the economic interests of the organization. This includes protecting against fluctuations in demand and production as well as controlling stock volumes and distribution. Effective inventory control ensures adequate supply while minimizing costs and better utilizing available stocks. Key aspects of inventory control include planning, procurement, receiving/inspection, storage/issuing, recording, verification, and material standardization. Various analysis methods can be used to classify inventory items for selective control, including ABC analysis, VED analysis