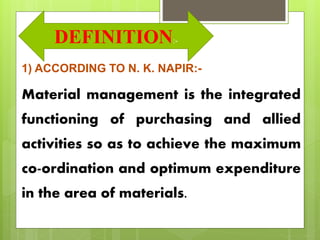

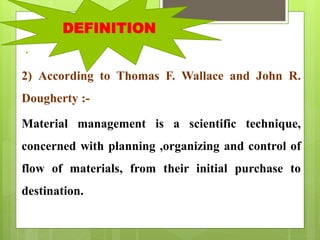

The document discusses material management in healthcare. It defines material management as the integrated functioning of purchasing and allied activities to achieve coordination and optimal expenditure on materials. The objectives of material management include reducing costs, maintaining continuous supply of materials, and standardization.

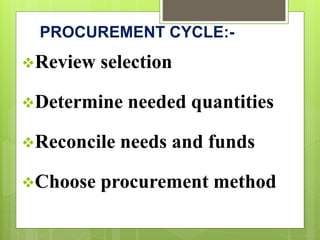

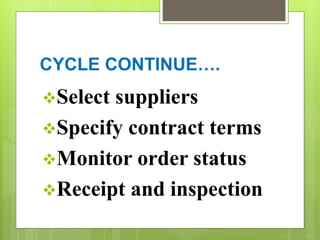

The key processes involved in material management are budgeting and planning, demand forecasting, procurement, receipt and inspection, storage, inventory control, distribution, and disposal. Effective material management procedures include taking regular inventories, requisitioning based on needs, receiving and inspecting incoming items, proper storage and protection of items, and ensuring proper use of items.

![8] USAGE:

Every effort must be made at all levels in the

organisation to utilize supplies in order to avoid

any form of wastage. Monitoring of consumption

should be effected through monthly supply usage

reports to work which summarize items consumed

department wise. Material cost can also be

decreased by appropriate selection of materials,

cheaper substitutes and standardization of

supplies.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-59-320.jpg)

![9] MAINTENANCE:

Proper maintenance of equipment, furniture, and

fixtures not only ensure their almost continuous

availability for use but also an extended life and

productivity for the items, thus resulting in lower

material costs. Time and costs of maintenance can

be reduced by consideration of following factors

during purchase :-](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-60-320.jpg)

![MAINTENANCE:-

A] Durability:- Since the equipment will be

handled by multiple users provide for an

element of over specification so that the

item is more sturdy than that available for

single person use in the home

environment.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-61-320.jpg)

![MAINTENANCE:-

B] Periodical disinfections: The

external surface of the items should be

washable and it should provide for

sterilization by moist heat, formalin

vapour, spirit or other disinfectants](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-62-320.jpg)

![MAINTENANCE CONT…..

C] Repair ability:- Go for items which are

more easily repairable.

D] Spare parts availability:-

Standardization of items and choosing

those easily available in the market

ensures easy availability of spare parts

required for repair and mainaintence.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-63-320.jpg)

![MAINTENANCE CONT…..

E] Operation and service manuals:

When purchasing sophisticated

equipment it is essential to obtain the

operating and service manuals so that

repairs can be attended to by the

hospital maintenance department

without relying on the supplier.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-64-320.jpg)

![MAINTENANCE CONT…..

F] Service contracts:- Better terms for

service are possible by negotiating

service contracts for maintenance prior

to purchase of the equipment. Such

contracts should specify minimum

number of preventive maintenance over

hard schedules, service charges etc.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-65-320.jpg)

![MAINTENANCE CONT…..

G] Stand by units: Since the hospital

work must carry on even when the

equipment is down, wherever possible

it is necessary to provide for

replacements to tide over the period of

repair .](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-66-320.jpg)

![10] DISPOSAL/ CONDEMNATION:

Indents are often improperly examined and

unofficial inventory builds up in wards /

departments because of hoarding of supplies.

Thus the nursing supervisors should

periodically inspect the stocks attached to

each ward and arrange for return of excess

stock/equipment.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-67-320.jpg)

![11] COLLUSION:

Frauds involving buyer vendor collusion can

account for a significant percentage of avoidable

materials costs. For commission either in cash or

kind purchase personnel may compromise the

interests of the hospital. The vendor finances such

payment by infiltrating the price, overstating the

quantity or through fraudulent payments.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-69-320.jpg)

![12] PILFERAGE:

Theft is not common. Items may be

pilfered by the transporters, receiver,

stores personnel or the users. Control of

hospital theft is possible with intensive

vigilance.](https://image.slidesharecdn.com/materialmanagementsem4-171211060447/85/Material-management-71-320.jpg)