This document provides an overview of industrial microbiology, including:

- Key aspects involve production of microbial products through fermentation and microorganisms' role in services like waste treatment.

- It discusses the history and developments in the field from traditional fermentation to modern genetic engineering applications.

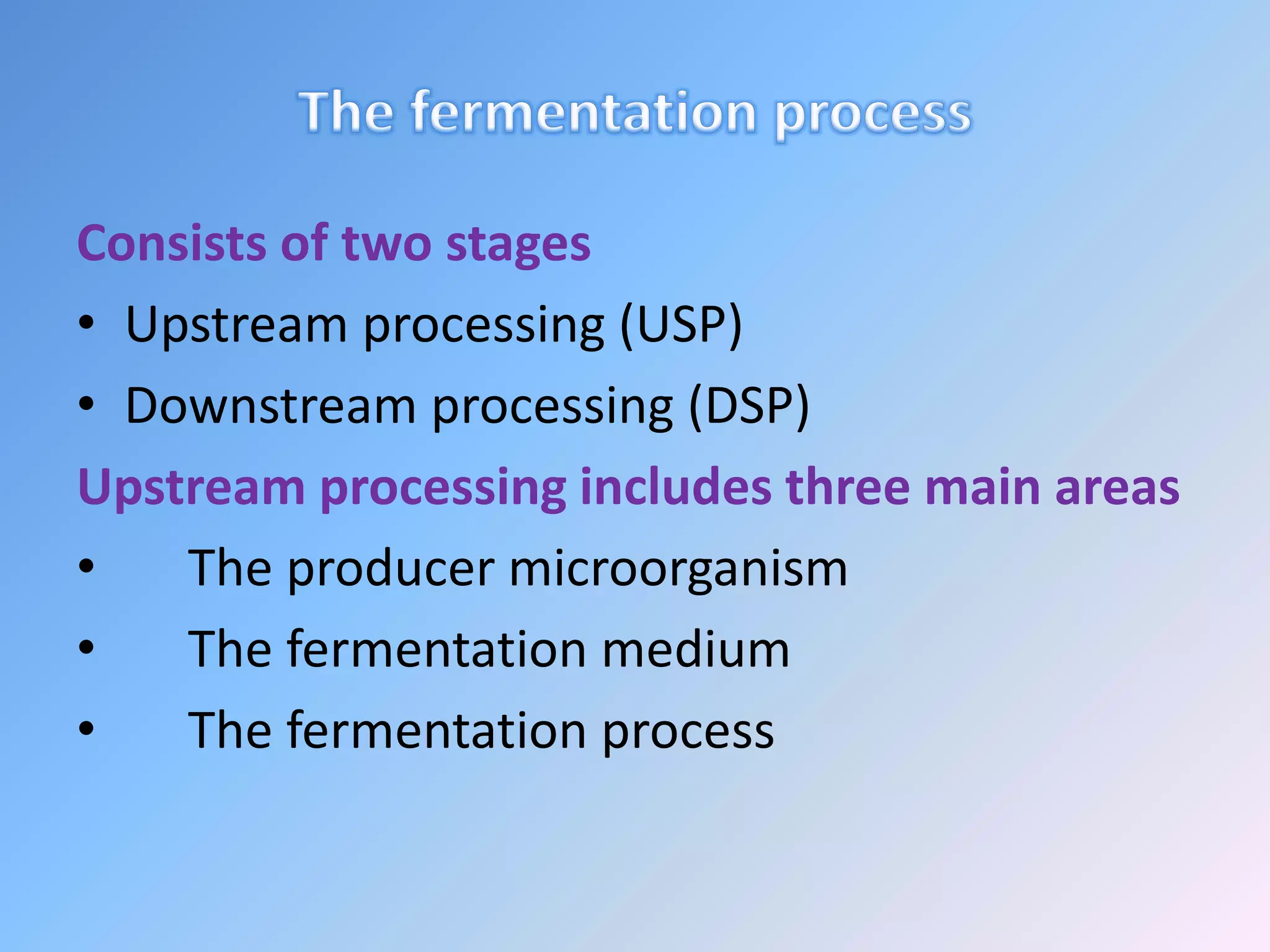

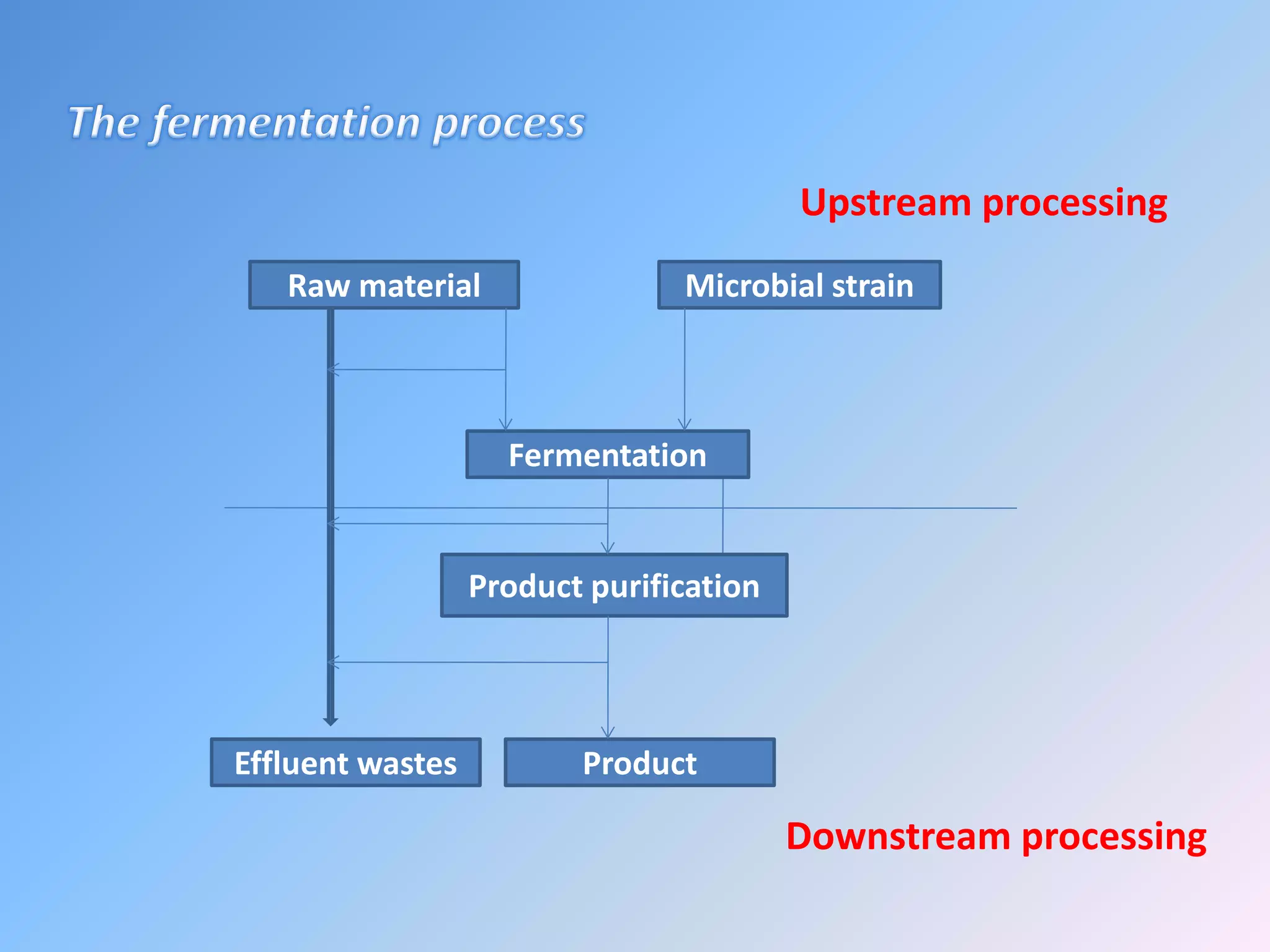

- The fermentation process involves upstream processing including selection of microorganisms, media, and process as well as downstream processing to recover products.

- Major fermentation products include foods, beverages, antibiotics, enzymes, chemicals and fuels while microorganisms also play important environmental roles in waste treatment.