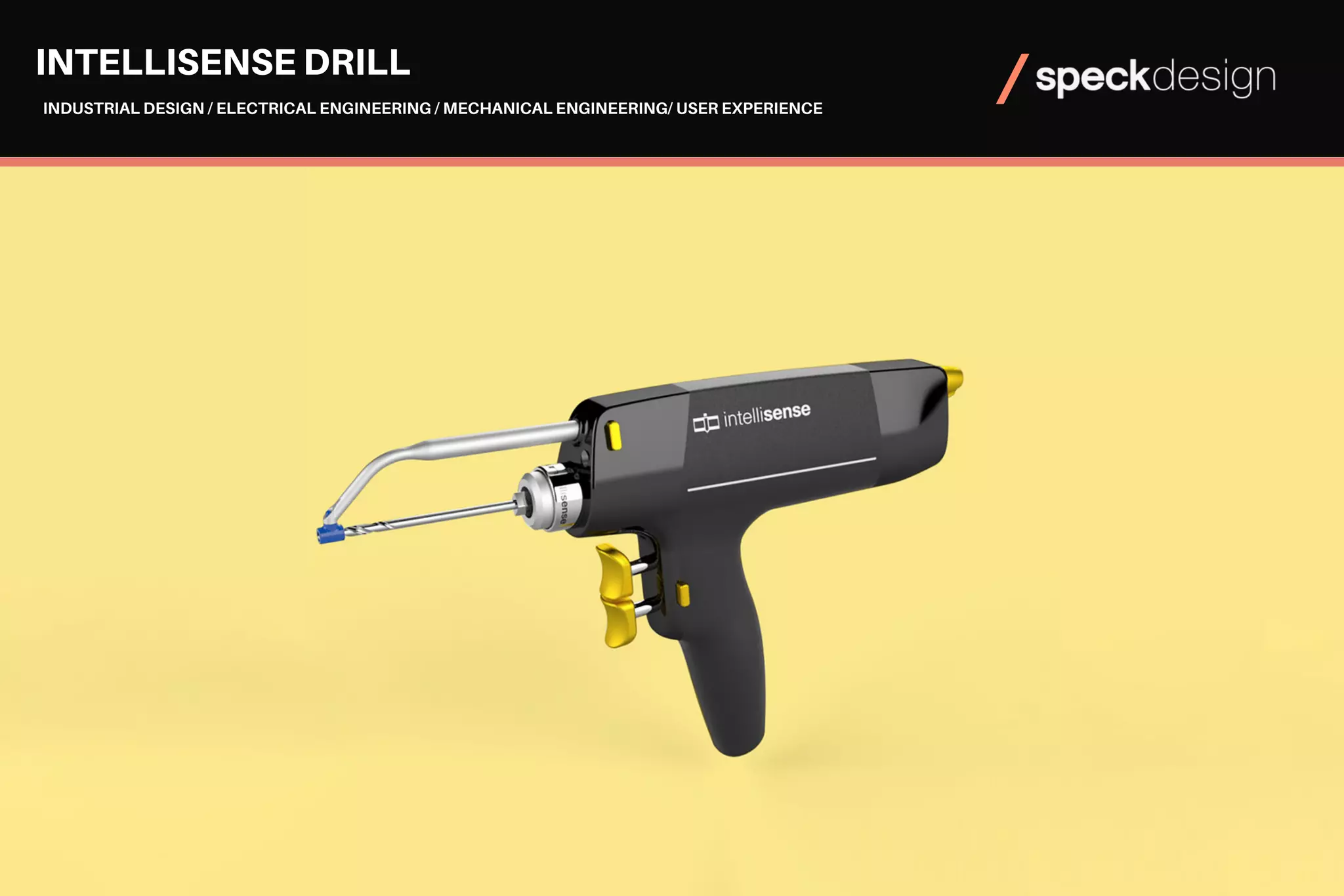

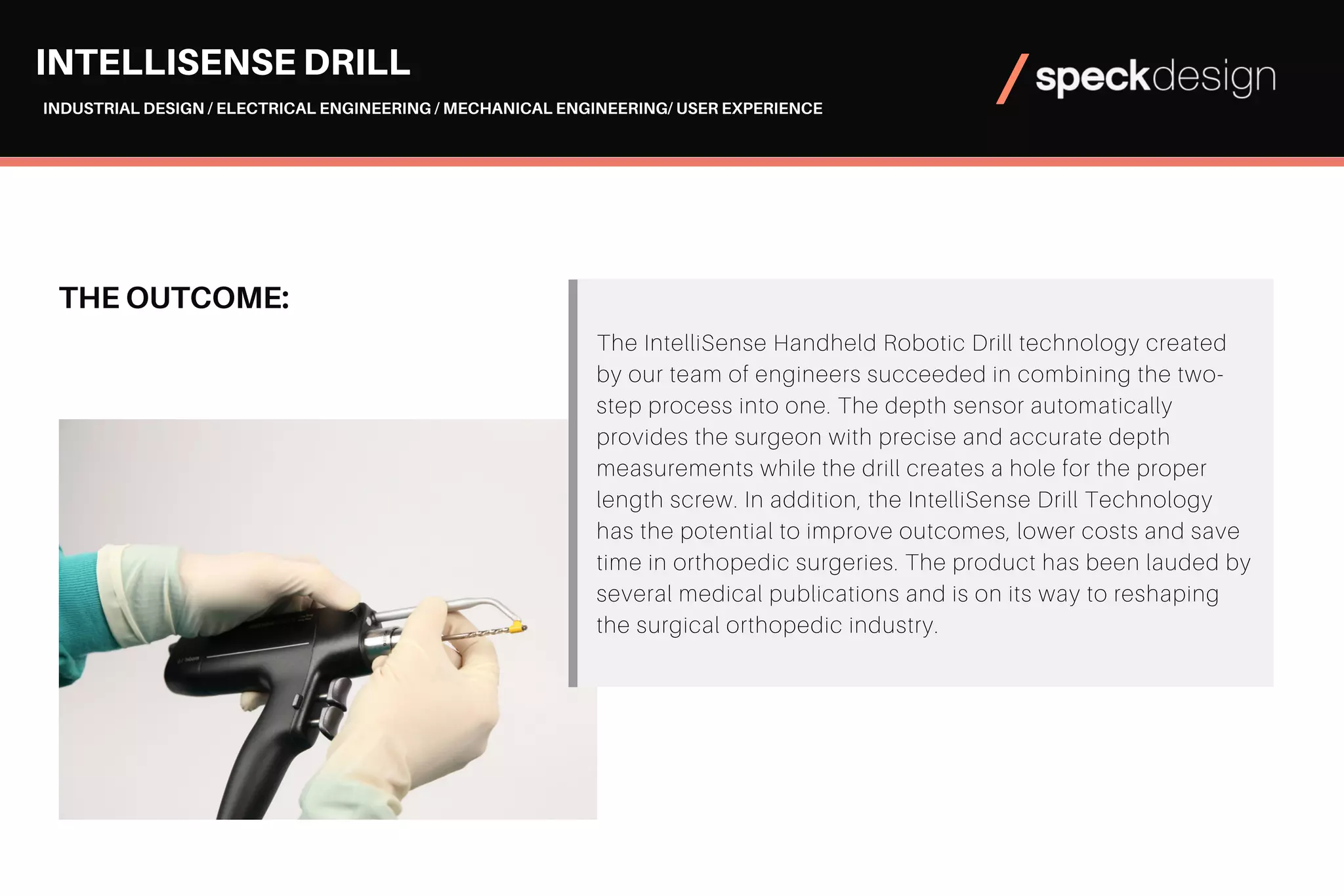

The Intellisense handheld robotic drill technology aims to enhance orthopedic surgeries by using multiple sensors to accurately measure drilling depth, preventing improper screw implantation. Developed by Speck Design for Dr. McGinley, it integrates real-time depth measurement with automated functionality to streamline the surgical process while ensuring safety and cost-efficiency. The device has garnered positive attention in medical publications and is poised to transform the orthopedic surgery landscape.