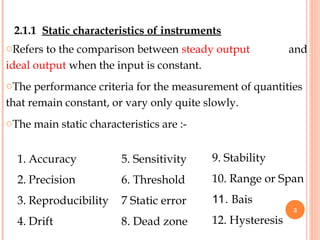

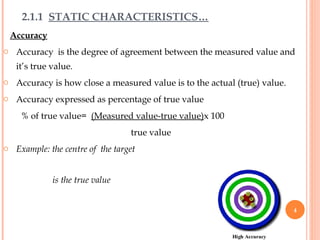

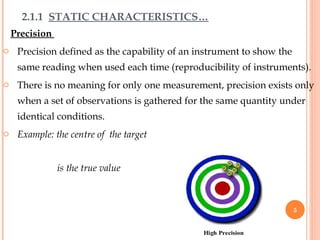

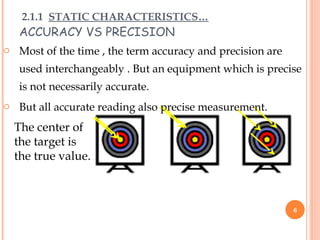

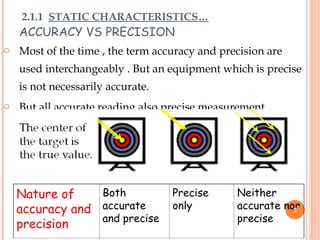

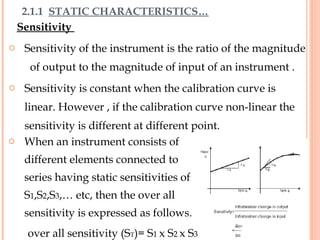

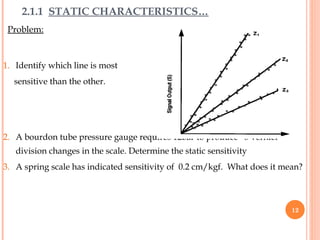

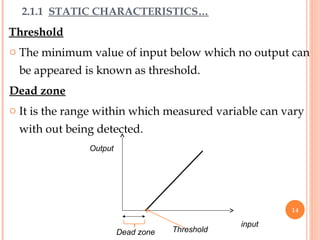

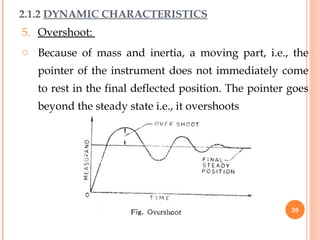

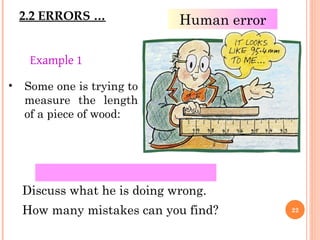

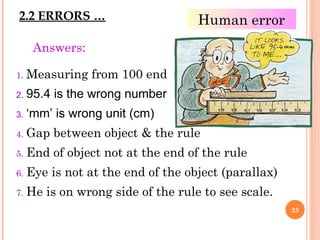

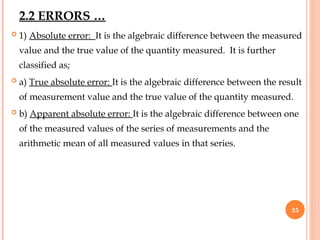

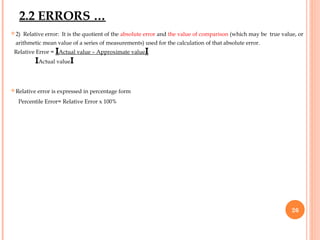

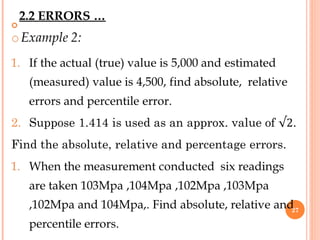

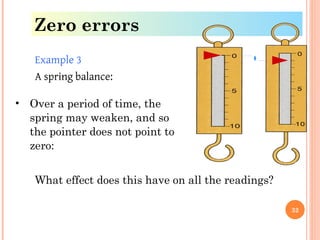

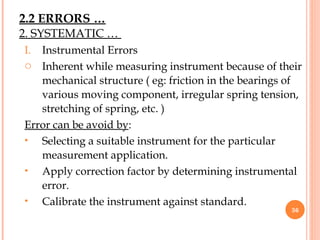

The document discusses performance characteristics and measurement errors of instruments, categorizing them into static and dynamic characteristics. It covers key concepts like accuracy, precision, sensitivity, and various types of errors, including gross, systematic, and random errors, highlighting the importance of calibration and environmental factors in measurement accuracy. Additionally, it emphasizes the distinctions between different types of errors and their impact on measurement reliability.