The document provides a limited warranty and liability terms for Fluke products:

1. Fluke warrants its products to be free from defects in material and workmanship for one year from the date of shipment. Parts, repairs, and services are warranted for 90 days.

2. The warranty is limited to the original buyer and does not cover misuse, abuse, or modifications to the product. Software is warranted to operate as specified for 90 days.

3. Fluke's sole obligation is to repair, replace, or refund the purchase price of defective products returned within the warranty period. Consequential damages are excluded from the warranty.

![805/805 FC

Users Manual

40

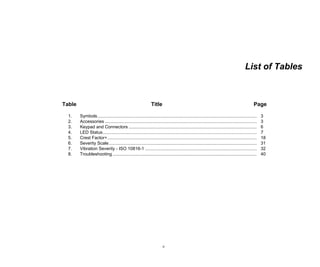

How to Troubleshoot

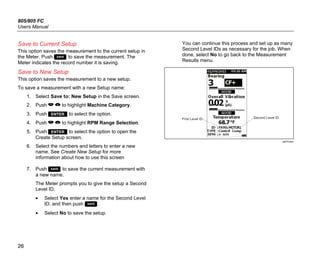

Table 8 is a list of problems, causes, and corrective actions for the Meter.

Table 8. Troubleshooting

Symptom Cause Corrective Action

Meter does not turn on. • The battery voltage is too

low.

• The battery connection is

loose.

1. Replace the batteries. See Battery Replacement on

page 38 for more information.

2. Ensure the batteries are properly aligned and

secured.

3. If the problem continues, contact the Fluke Service

Center [1]

for technical support.

Buttons do not operate. Meter

does not operate.

1. Restart the Meter.

2. If the problem continues, contact the Fluke Service

Center [1]

for technical support.

The Meter cannot connect with

the PC.

The USB cable is not

connected correctly.

Correctly connect the USB cable. See USB on page 16 for

more information.

• The USB cable is

damaged.

• Check that USB drivers

are installed in the

PC/Laptop.

1. Examine the USB cable for any damage. If you find

damage, contact the Fluke Service Center [1]

for a

replacement cable.

2. Reboot the PC.

PC does not see the Meter is

connected.

Reboot the PC.

Error Message: Measurement

invalid. Please hold to surface

for full duration.

The Meter was not held on

the surface for a sufficient

time or with sufficient force.

Push Meter onto test surface until green LED turns on.

Wait until the green LED turns off. See About

Measurements on page 17 for more information.

[1] See How to Contact Fluke on page 1.](https://image.slidesharecdn.com/805umeng0200-190603033805/85/H-ng-d-n-s-d-ng-Fluke-805-50-320.jpg)