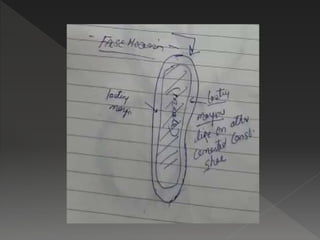

A moccasin is a soft leather shoe consisting of a sole and sides stitched together at the top. It has a soft, flexible sole and decorated upper. Moccasins were traditionally worn by Native Americans and Canadians for outdoor use. There are different styles depending on the terrain, like hard-soled moccasins for rocky plains. A driving moccasin is a modern version with added rubber tabs. Moccasins provide foot protection while maintaining flexibility and comfort.