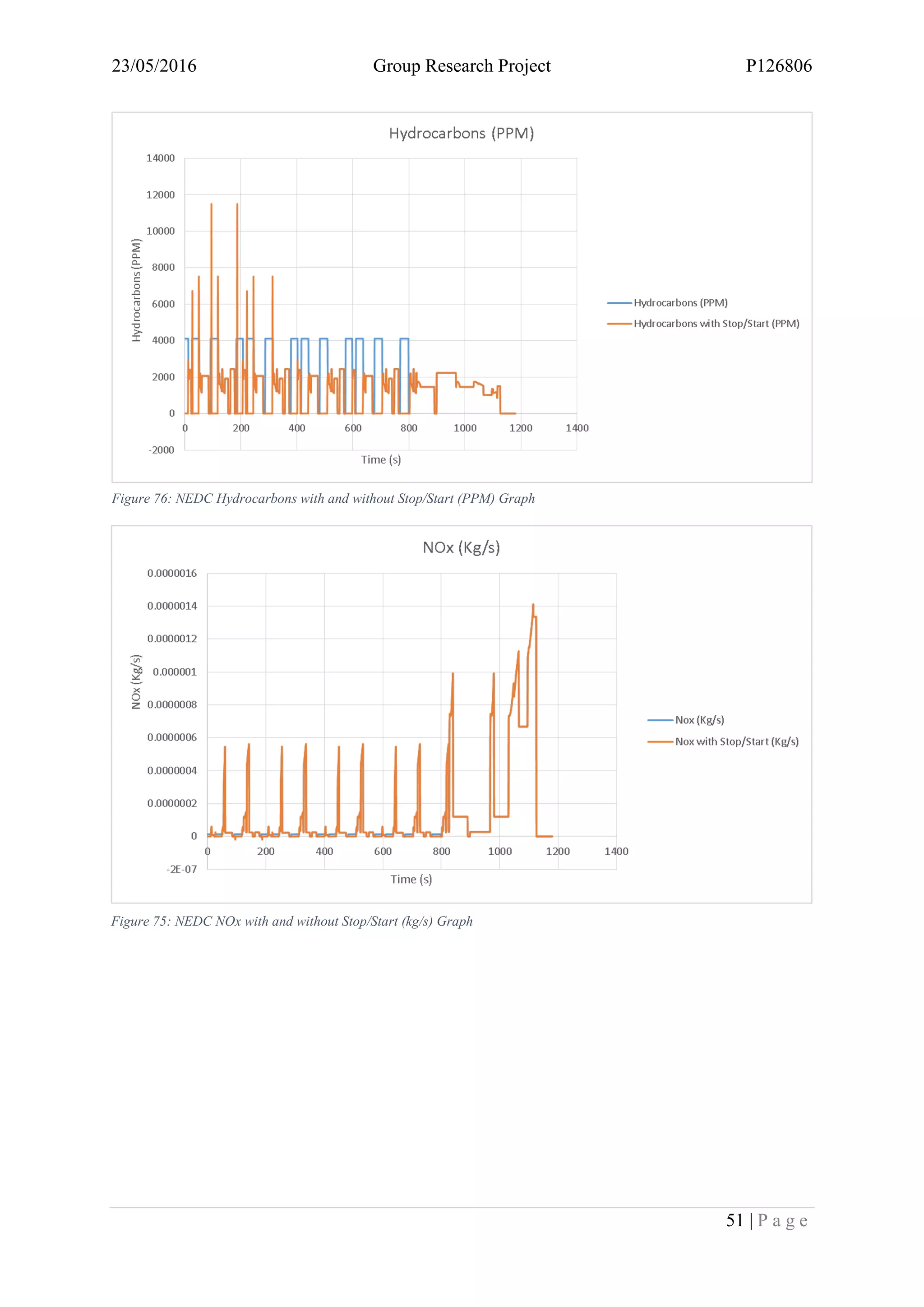

This document appears to be a group research project report that includes 81 figures analyzing and comparing vehicle drive cycles and engine performance. Specifically, it analyzes the New European Driving Cycle (NEDC) and Worldwide harmonized Light vehicles Test Procedure (WLTP) drive cycles. It also models the effects of stop-start systems and varying engine parameters on fuel consumption, emissions and performance.