Google Cloud Platform For Architects Design And Manage Powerful Cloud Solutions Raj

Google Cloud Platform For Architects Design And Manage Powerful Cloud Solutions Raj

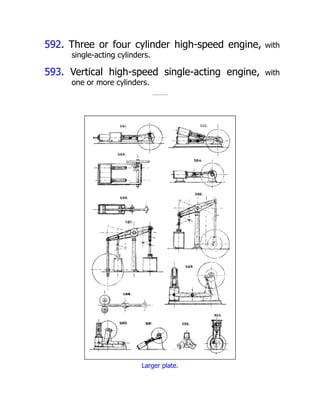

Google Cloud Platform For Architects Design And Manage Powerful Cloud Solutions Raj