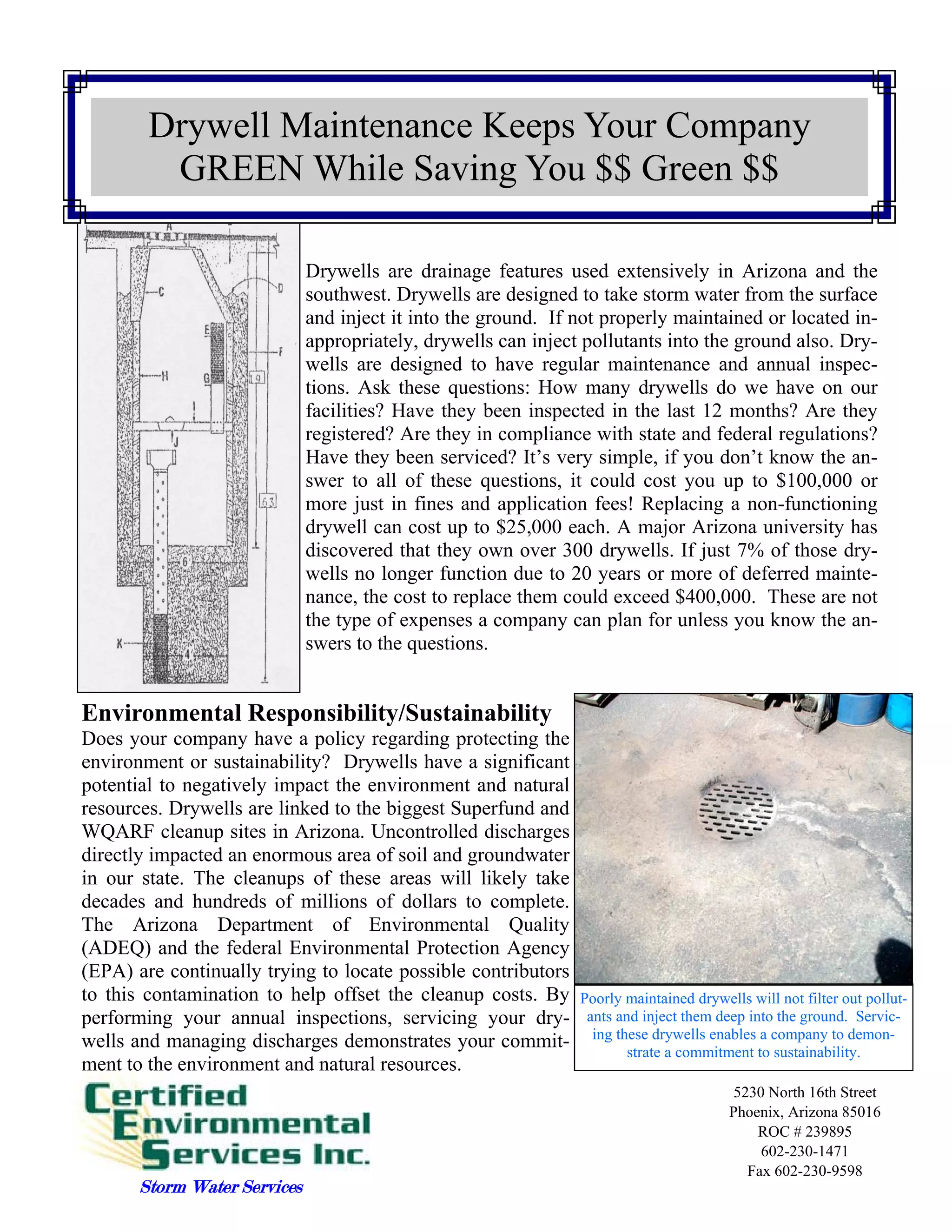

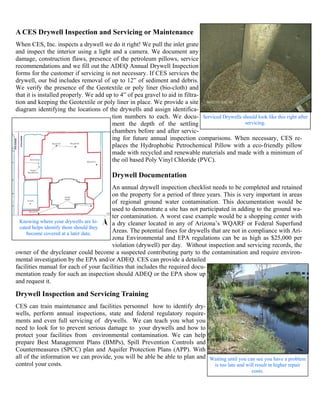

Poorly maintained drywells can negatively impact the environment by injecting pollutants deep underground. Companies should regularly inspect and service their drywells to comply with regulations, avoid fines, and demonstrate commitment to sustainability. Unregistered or non-functioning drywells that are not properly maintained can cost companies thousands of dollars to replace.