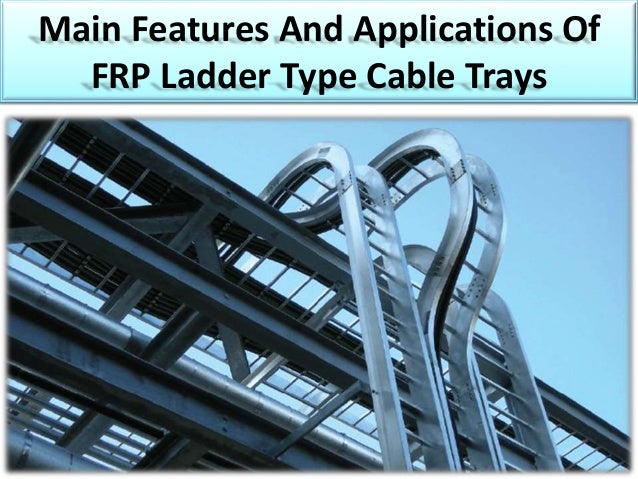

FRP ladder type cable trays are designed to support and protect various cables while offering benefits such as heat dispensation, ease of access for maintenance, and lesser moisture accumulation. Constructed from fiberglass reinforced plastic, these trays are lightweight, durable, and resistant to corrosion, chemicals, and fire, making them suitable for harsh industrial environments. Their customizable nature and variety of applications, including in chemical plants and offshore installations, emphasize their versatility and practicality in modern electrical infrastructure.