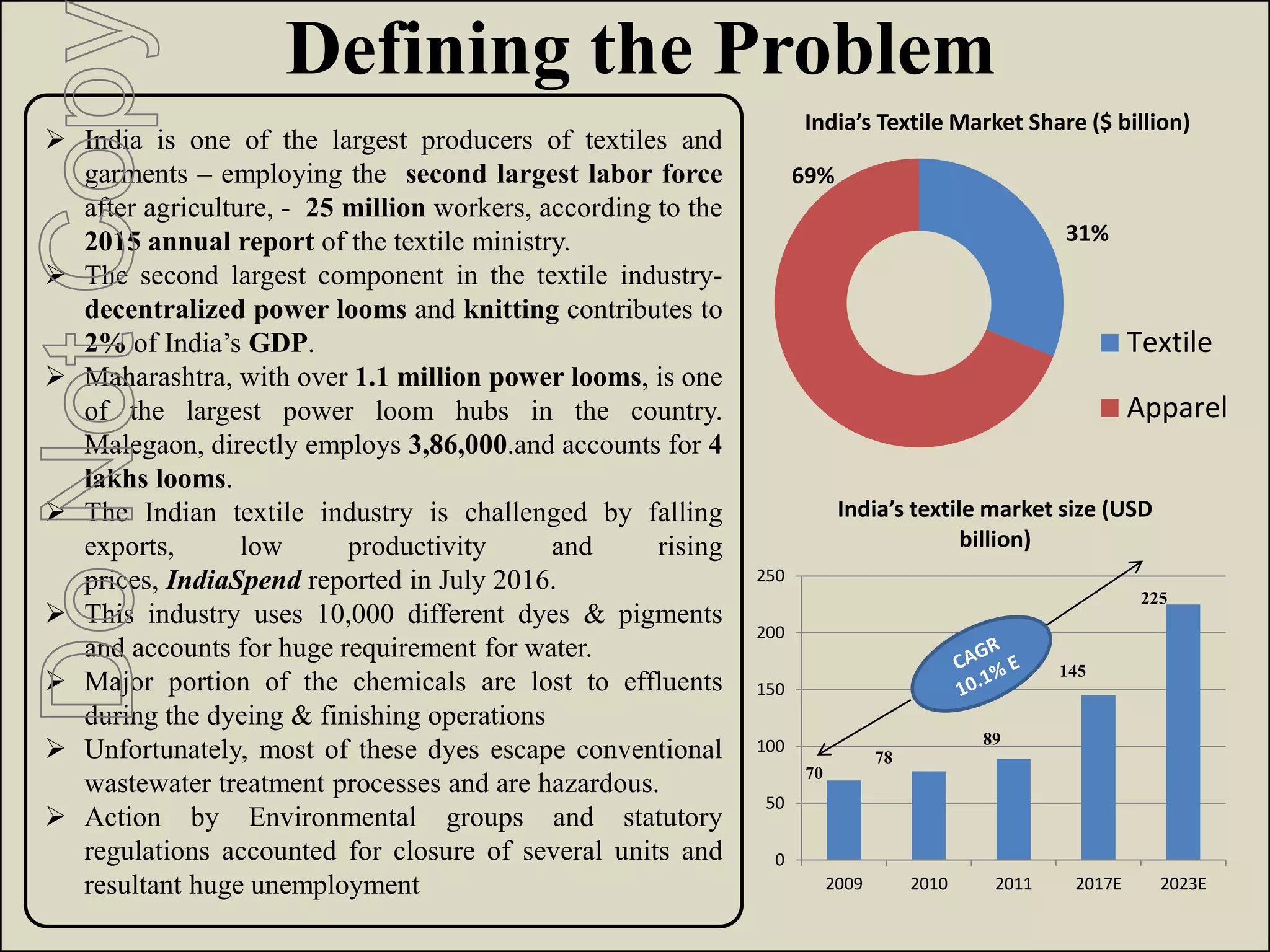

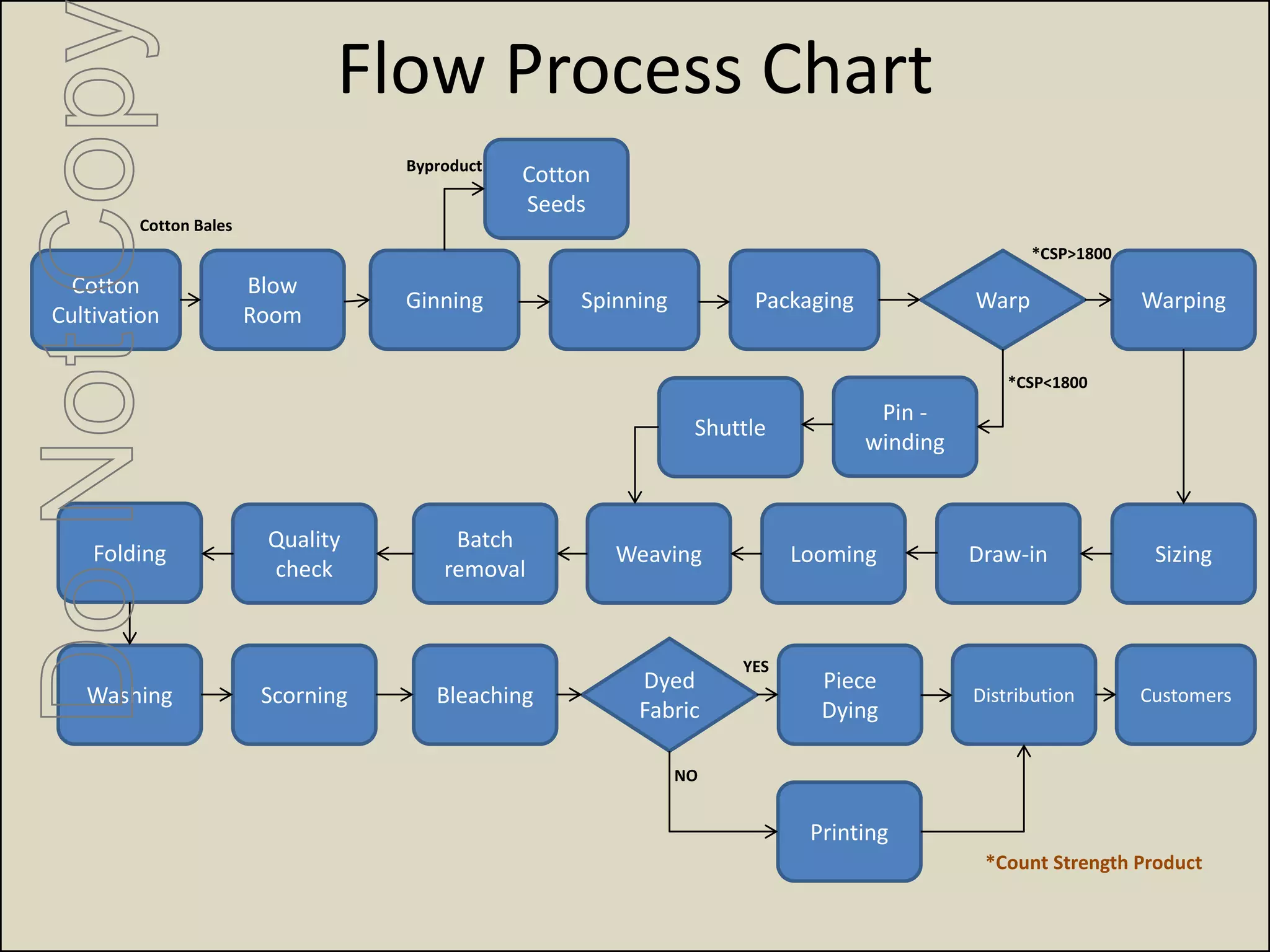

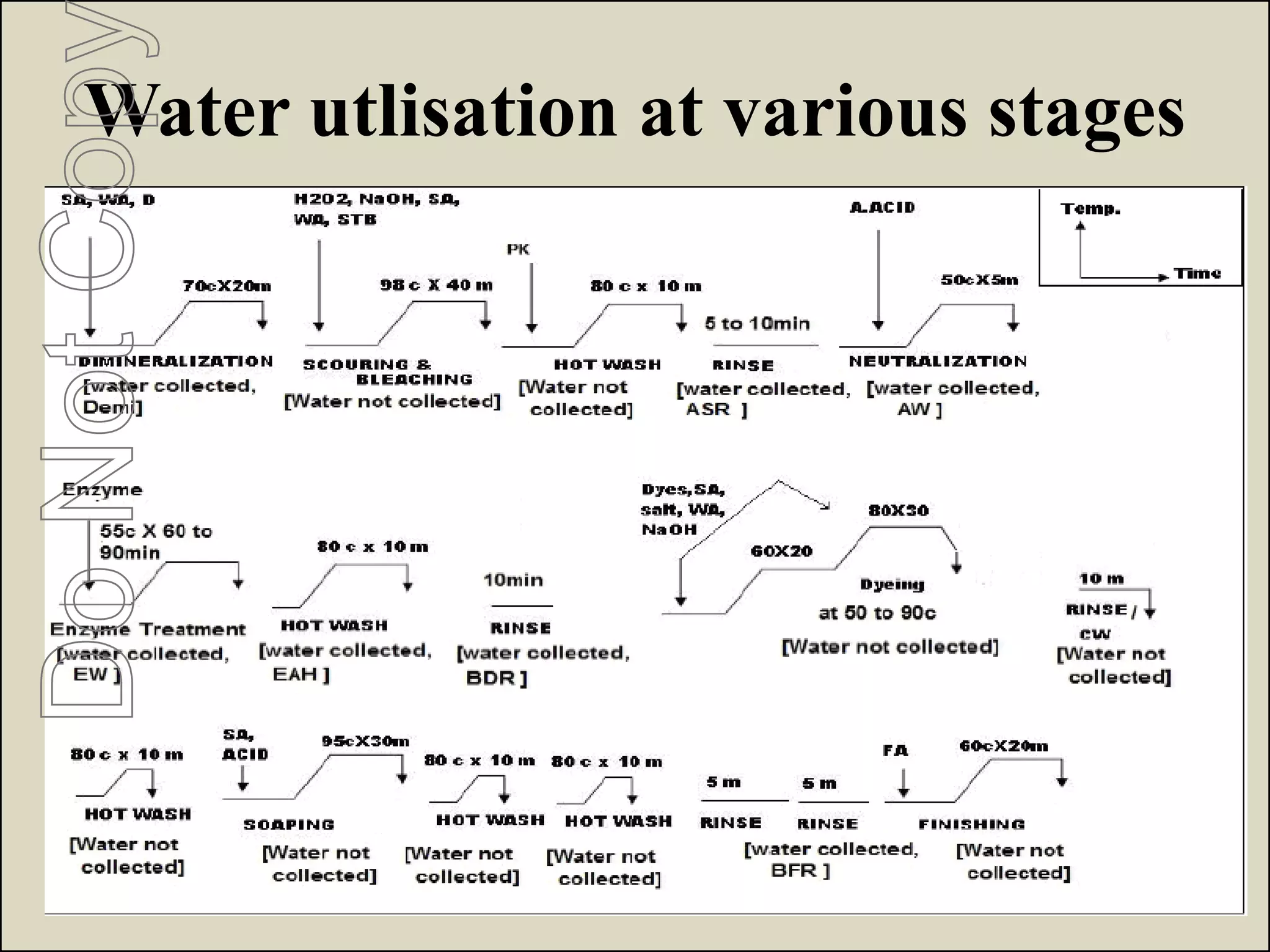

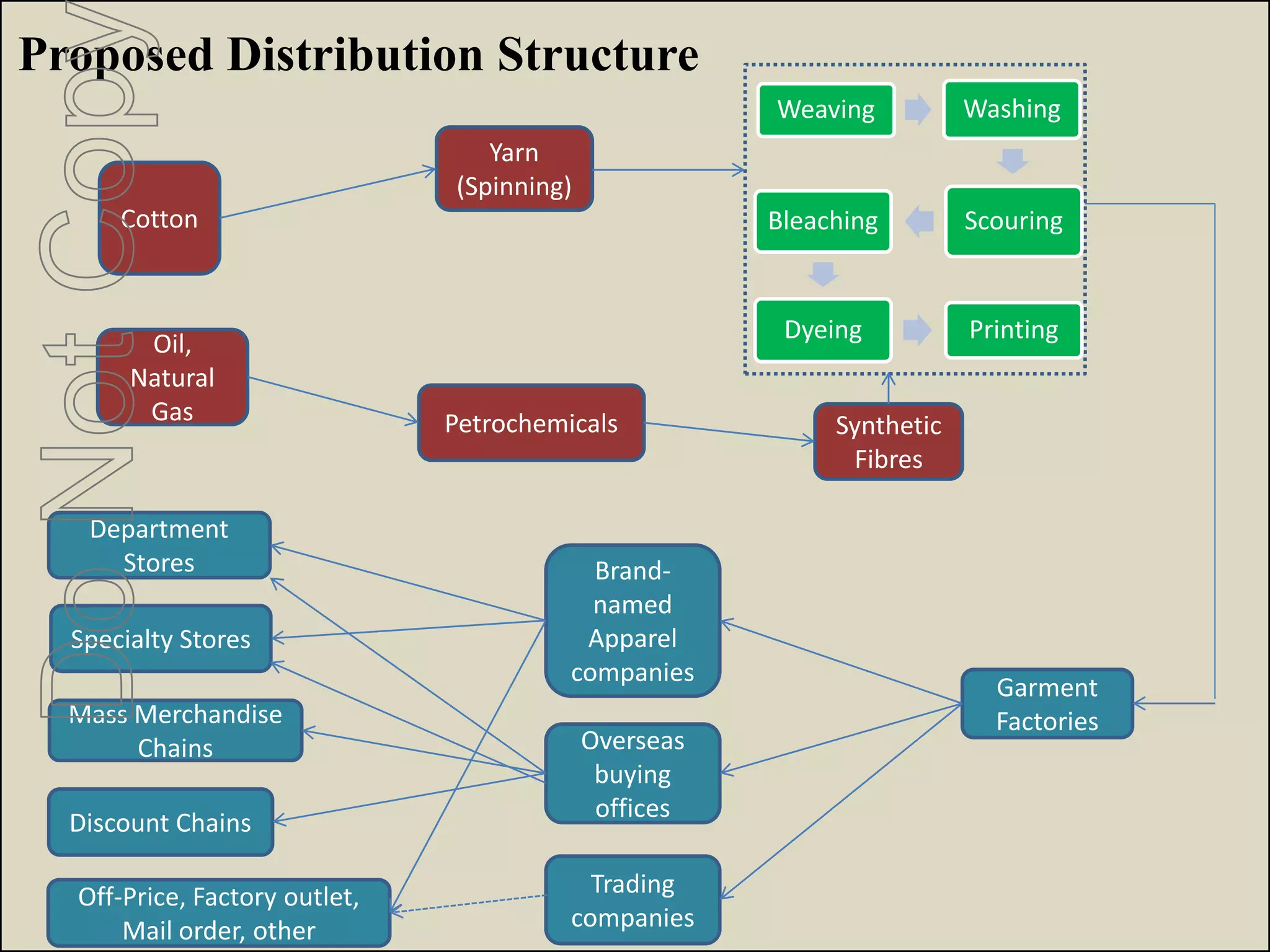

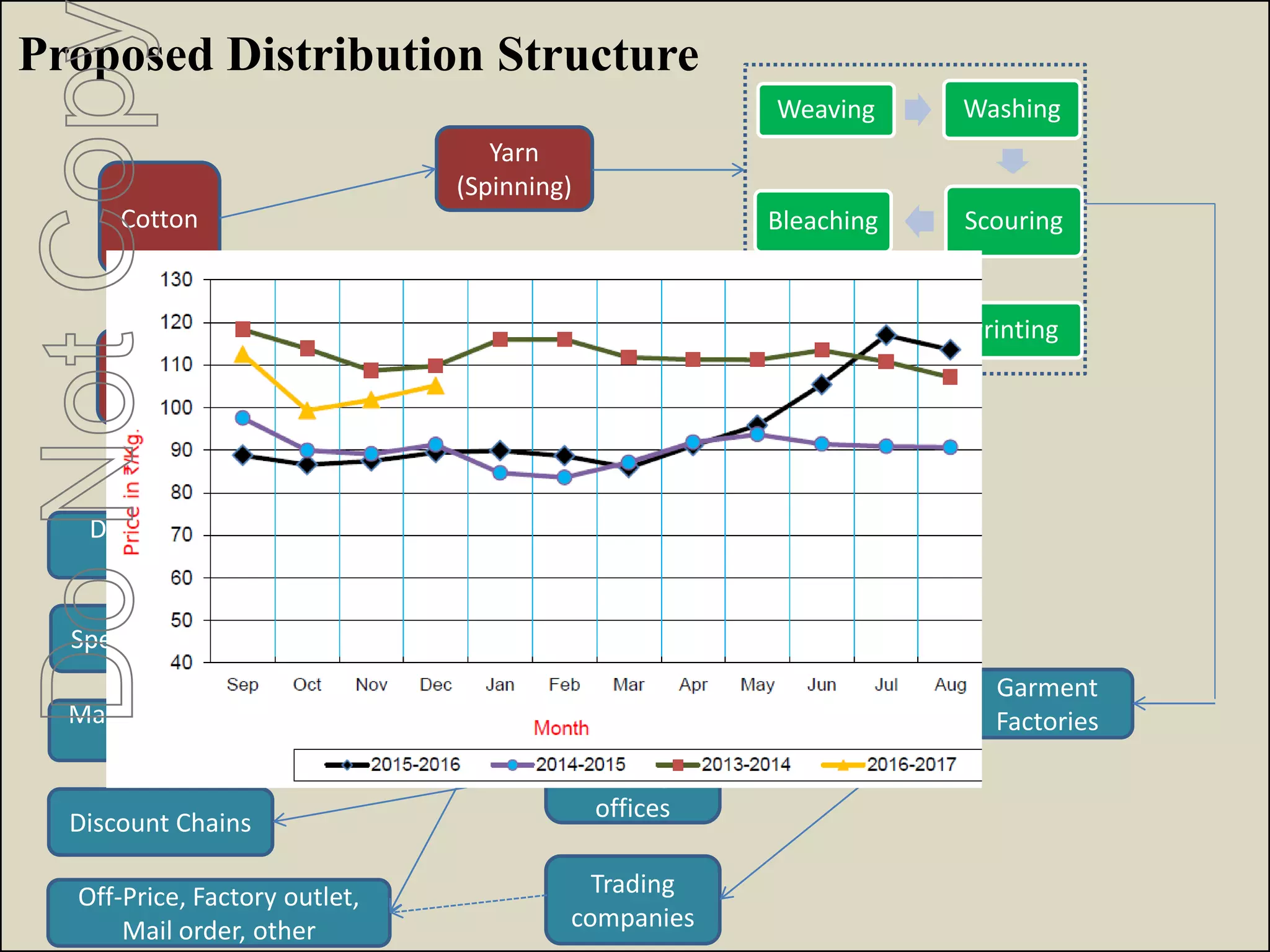

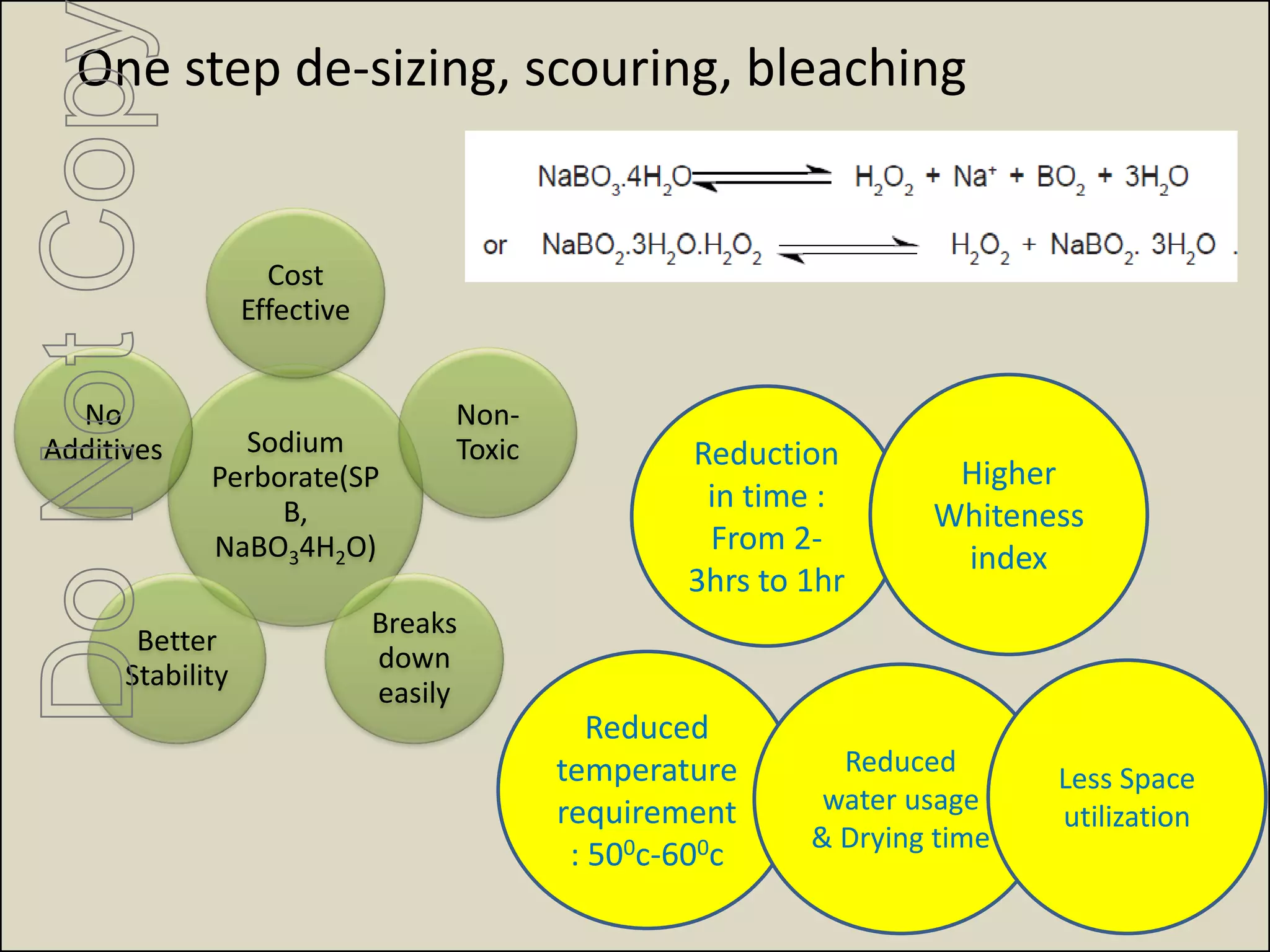

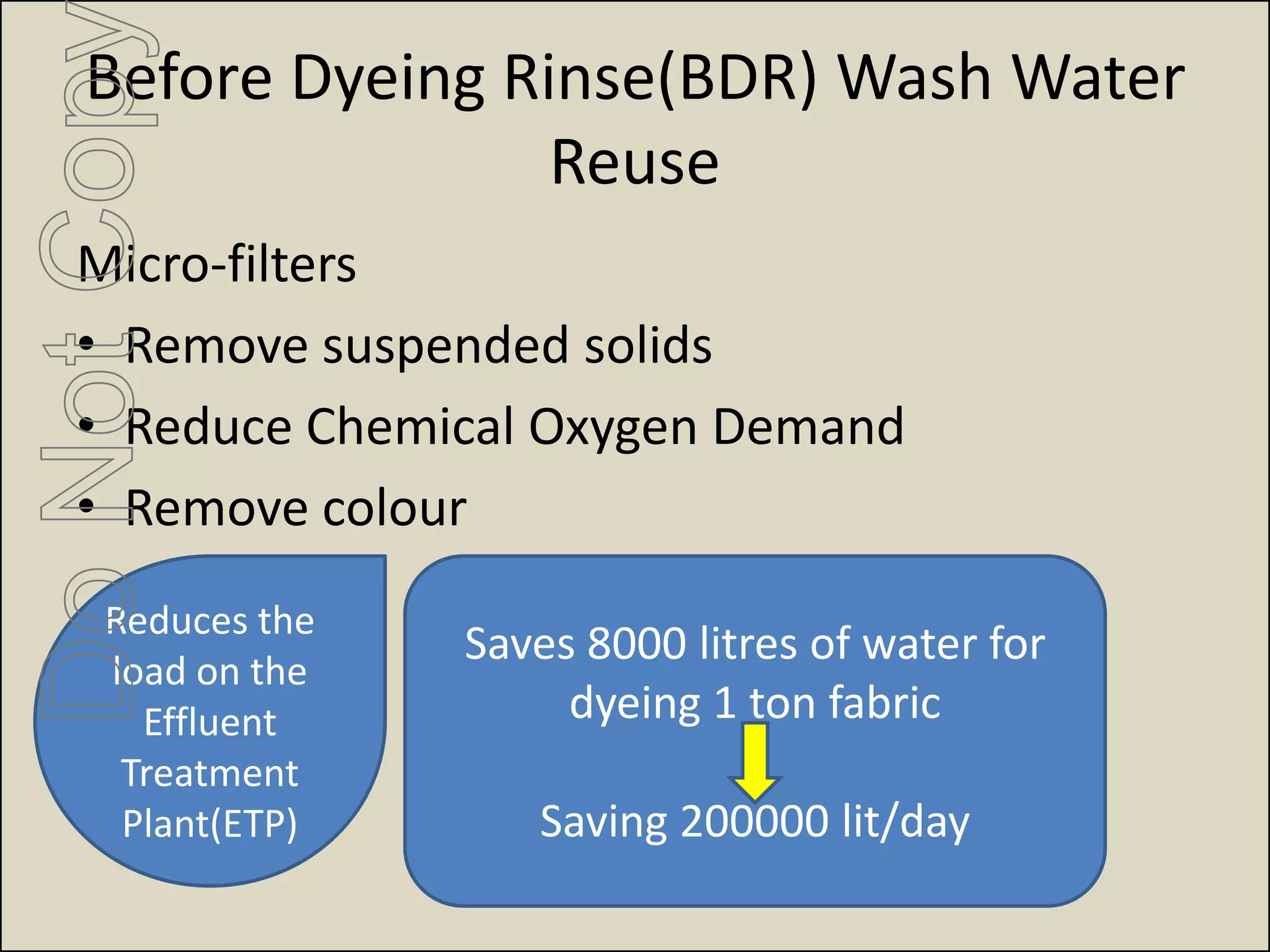

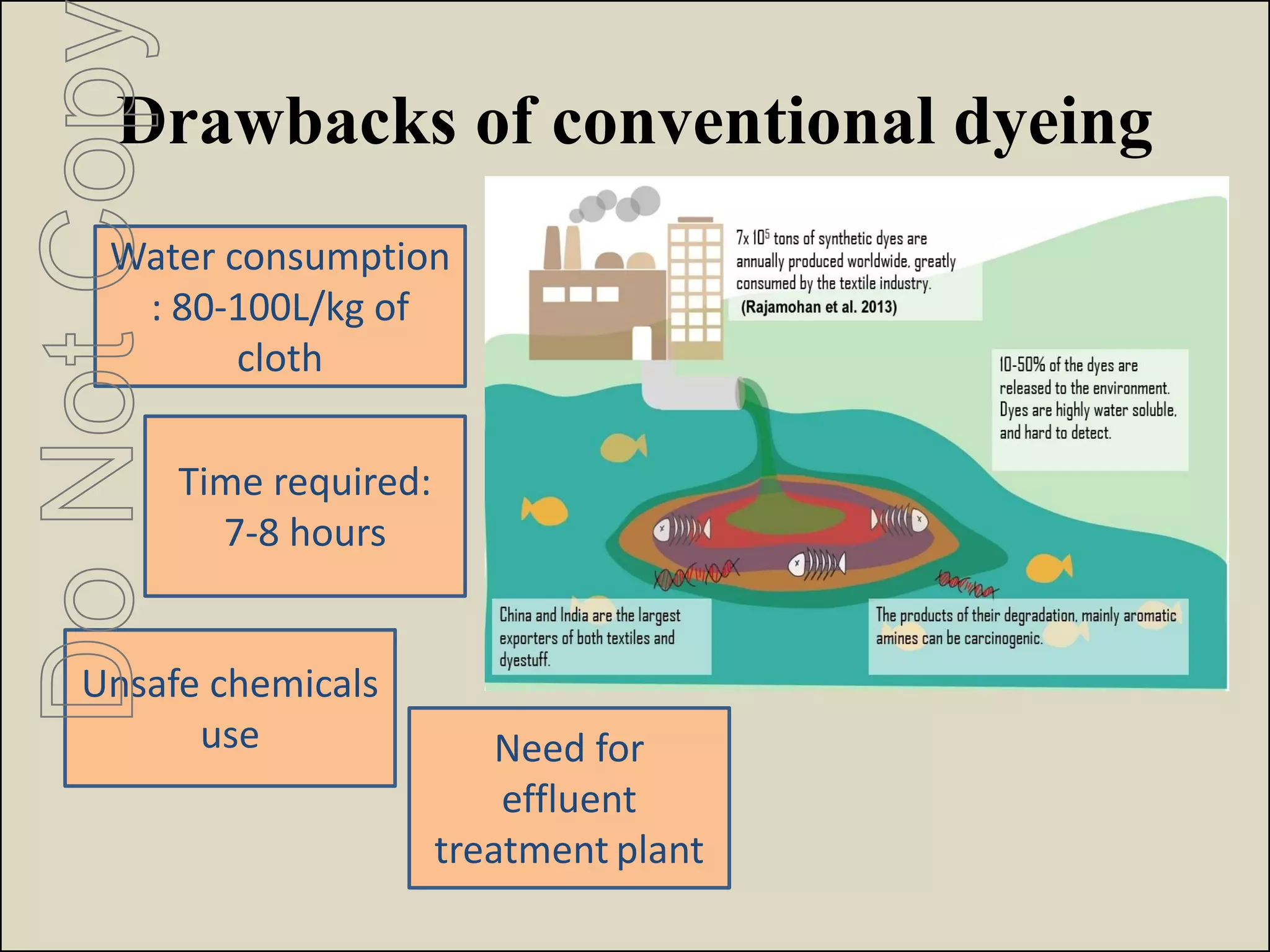

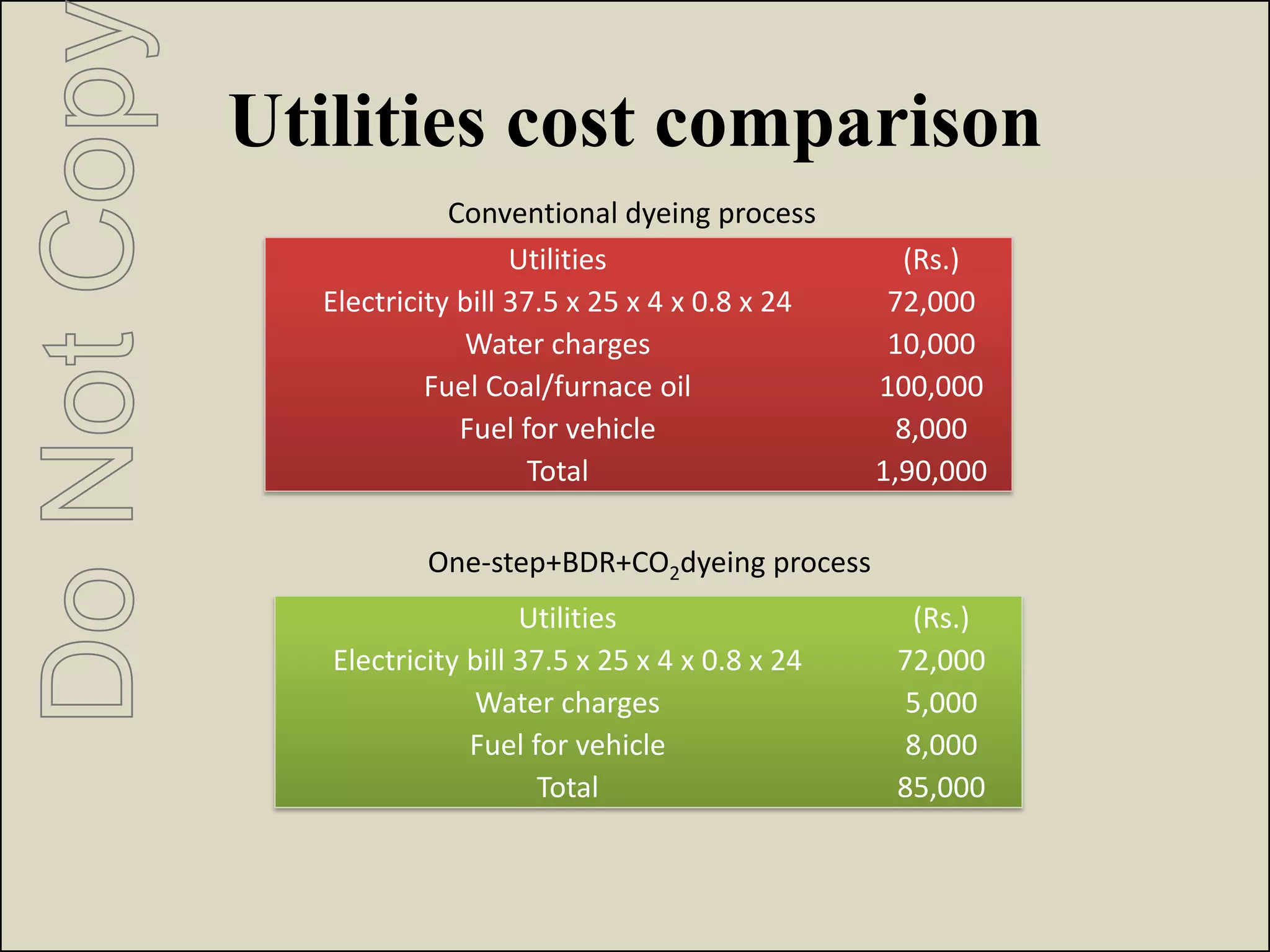

The document discusses the challenges and opportunities within India's textile industry, which employs 25 million workers and contributes significantly to the GDP. It highlights the environmental issues related to textile dyeing, including excessive water use, harmful chemicals, and inadequate waste treatment, and proposes solutions like eco-friendly dyeing processes. Additionally, it compares the costs and utilities of conventional dyeing methods with advanced techniques that utilize CO2, emphasizing benefits such as reduced water consumption and environmental impact.