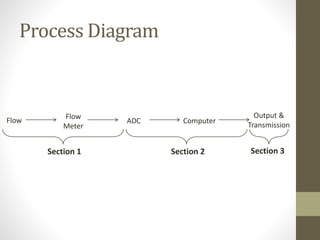

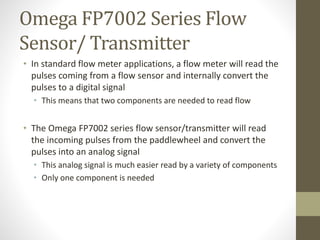

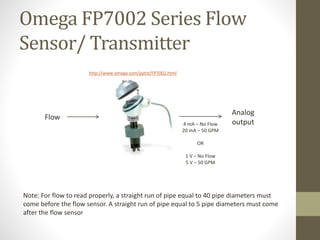

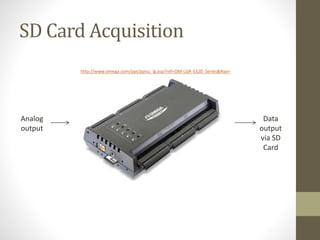

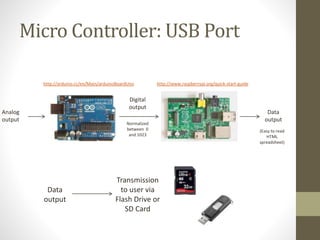

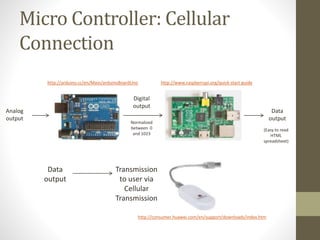

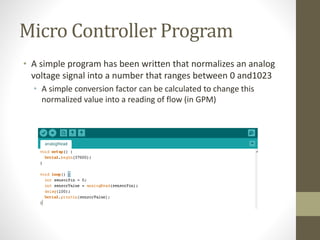

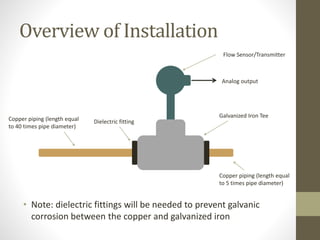

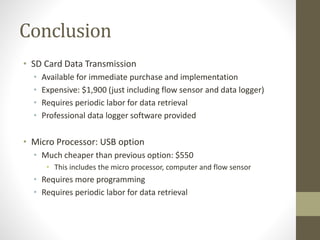

This document summarizes research into solutions for acquiring flow meter readings from a water feature to understand water losses. It identifies measuring flow, transmitting data wirelessly, manipulating data easily, and having a reliable, cost-effective system as key requirements. Potential solutions investigated include using a paddlewheel sensor with SD card or cellular data transmission, or a microcontroller with USB or wireless transmission. An Omega flow sensor/transmitter combined with a data logger or microcontroller is recommended to meet the requirements.