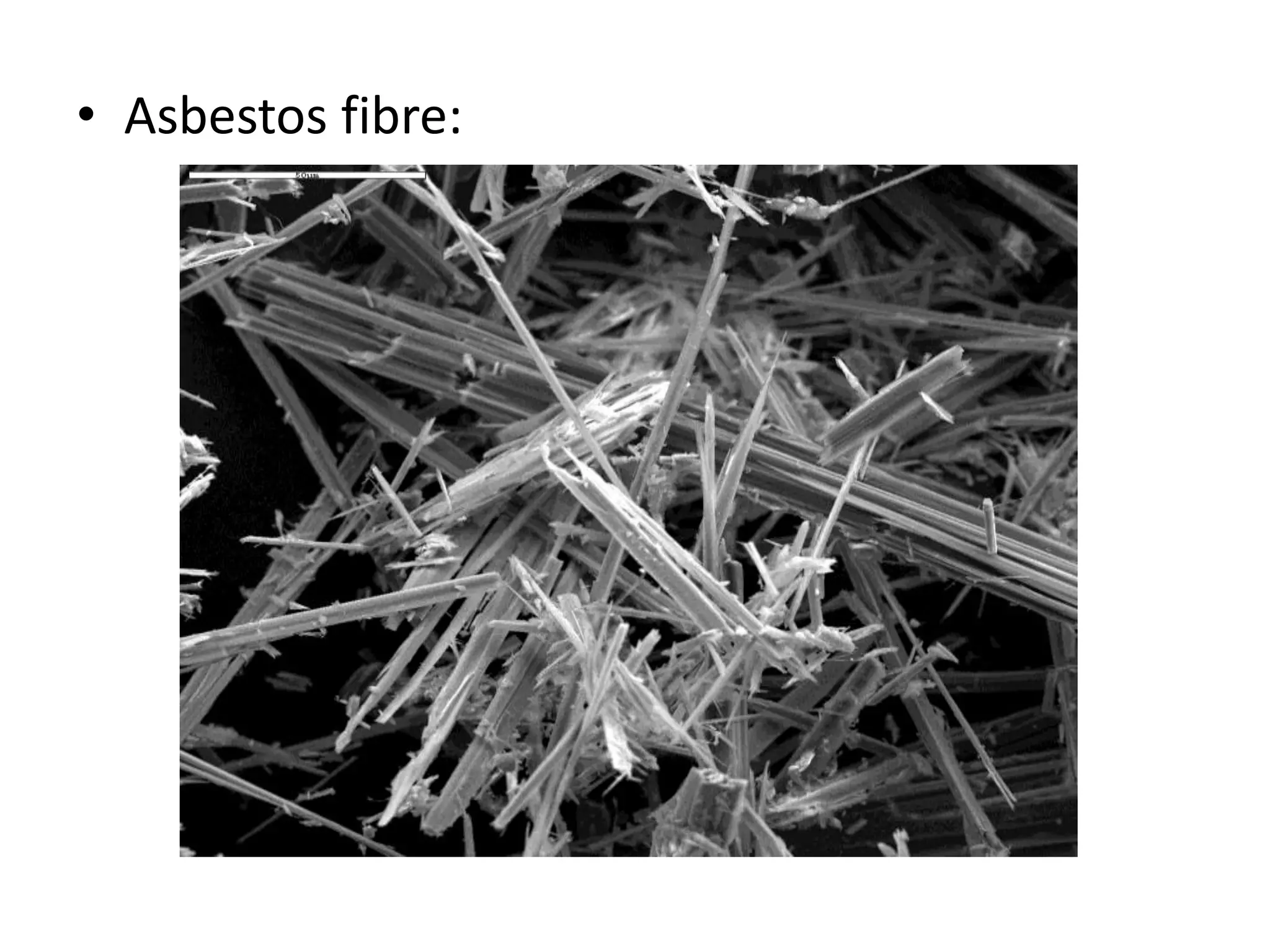

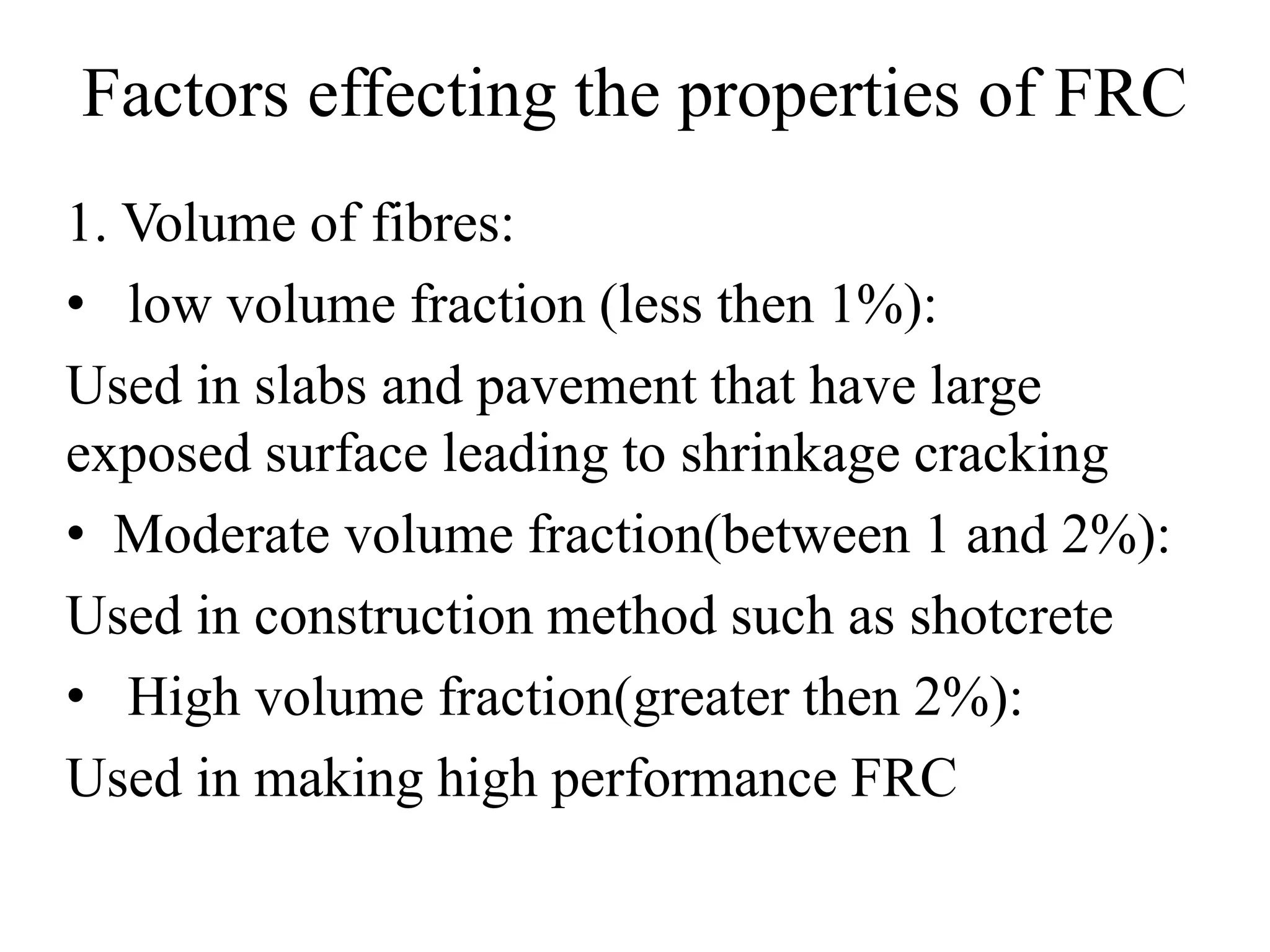

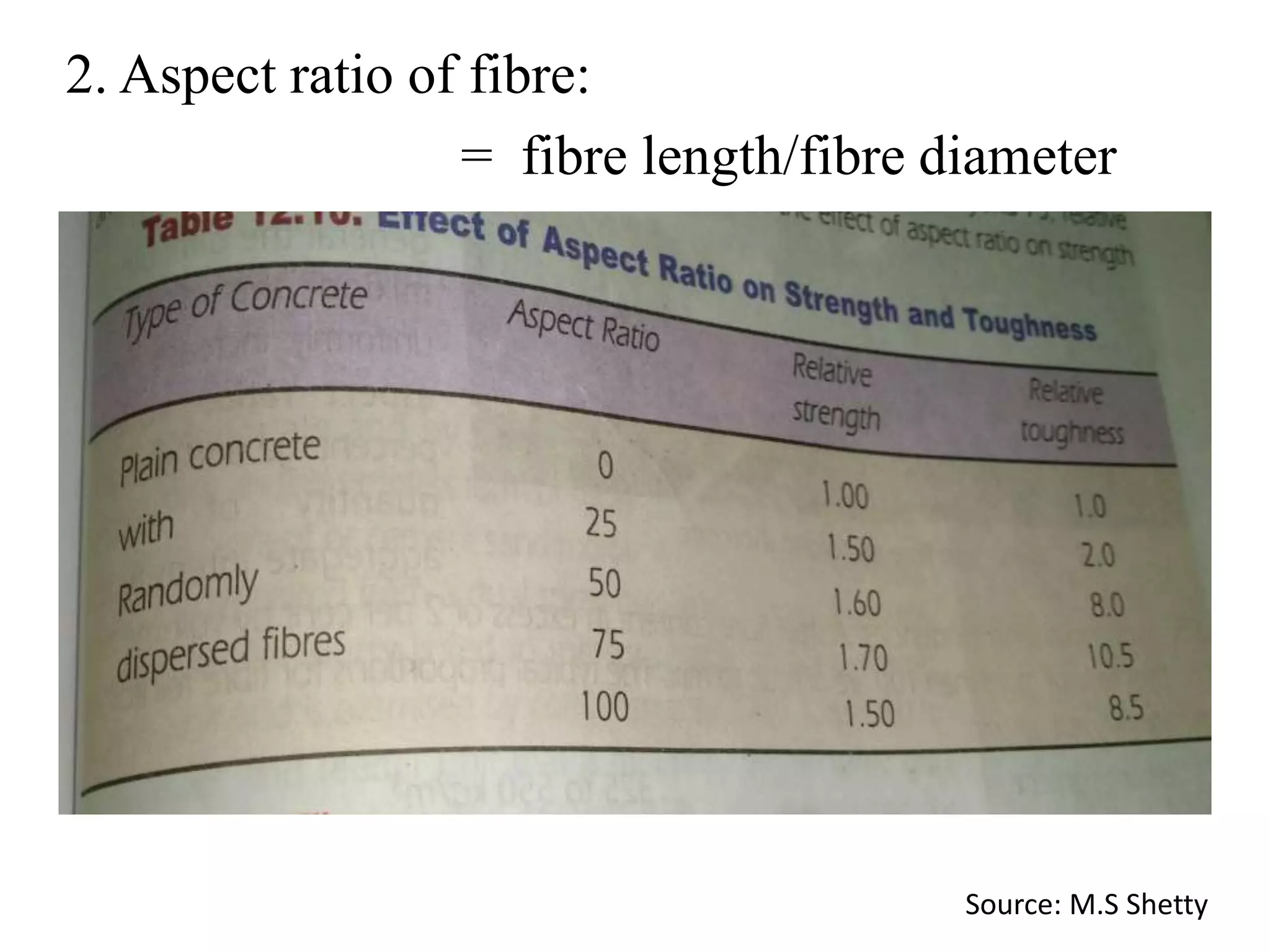

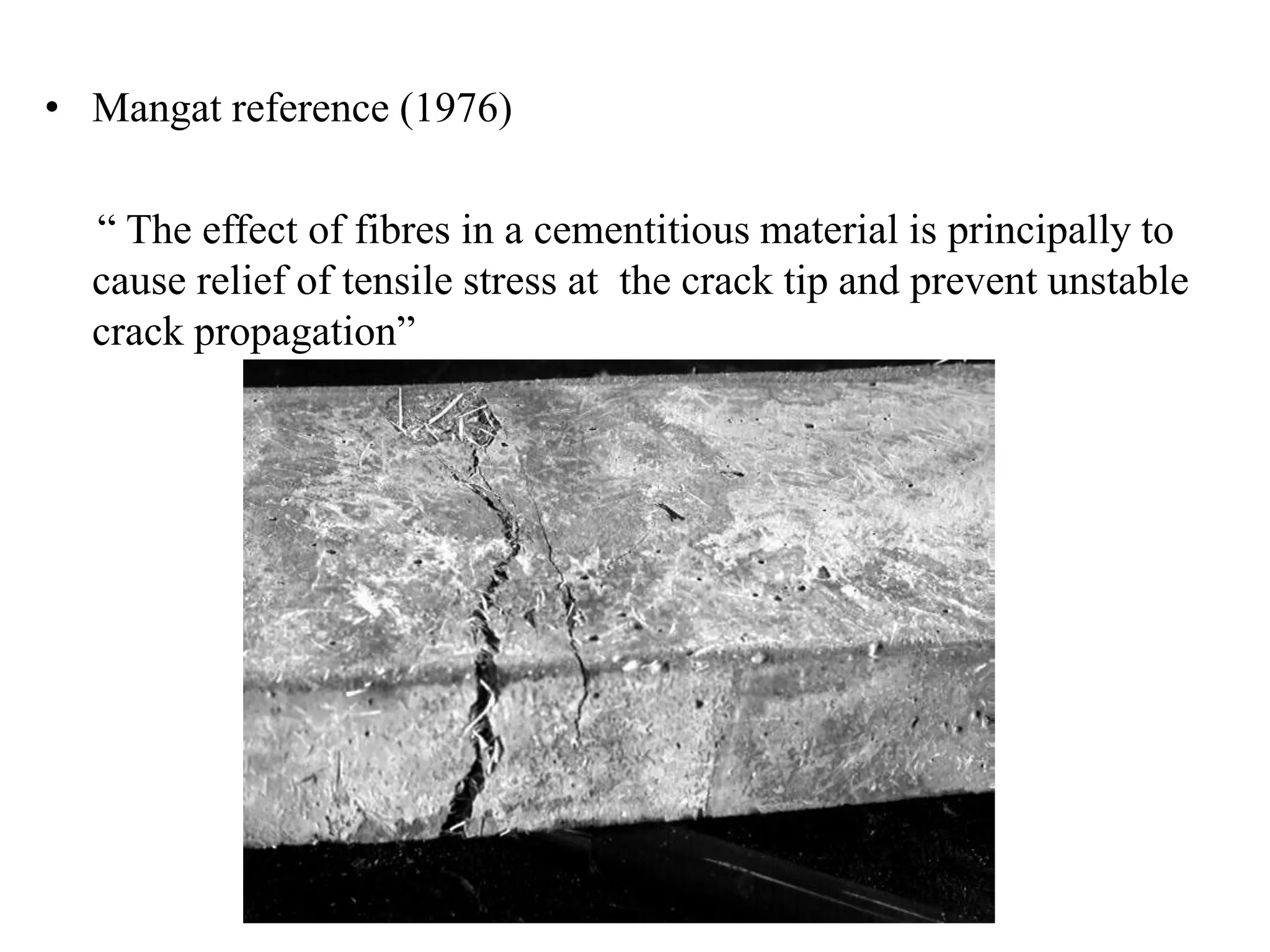

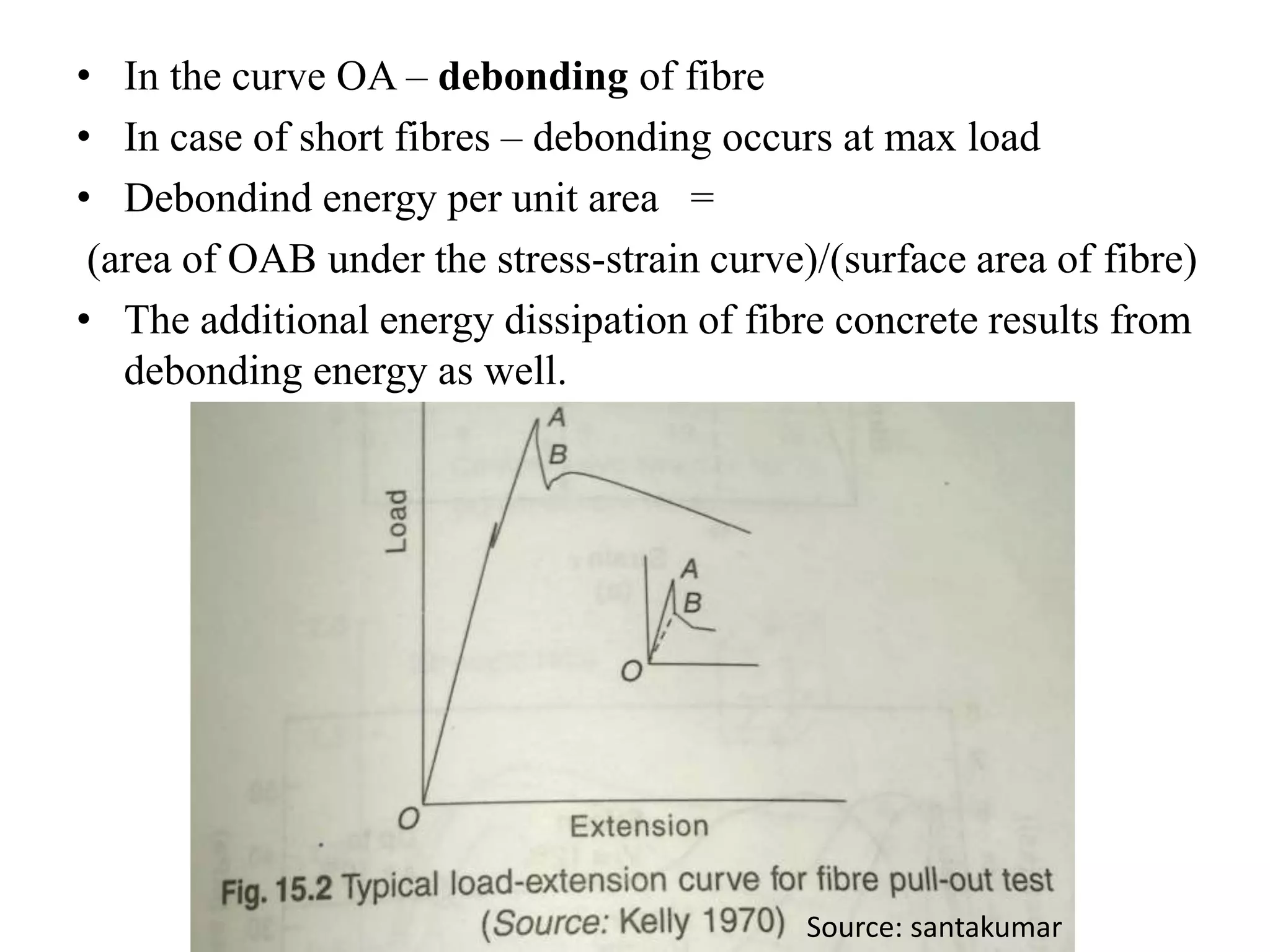

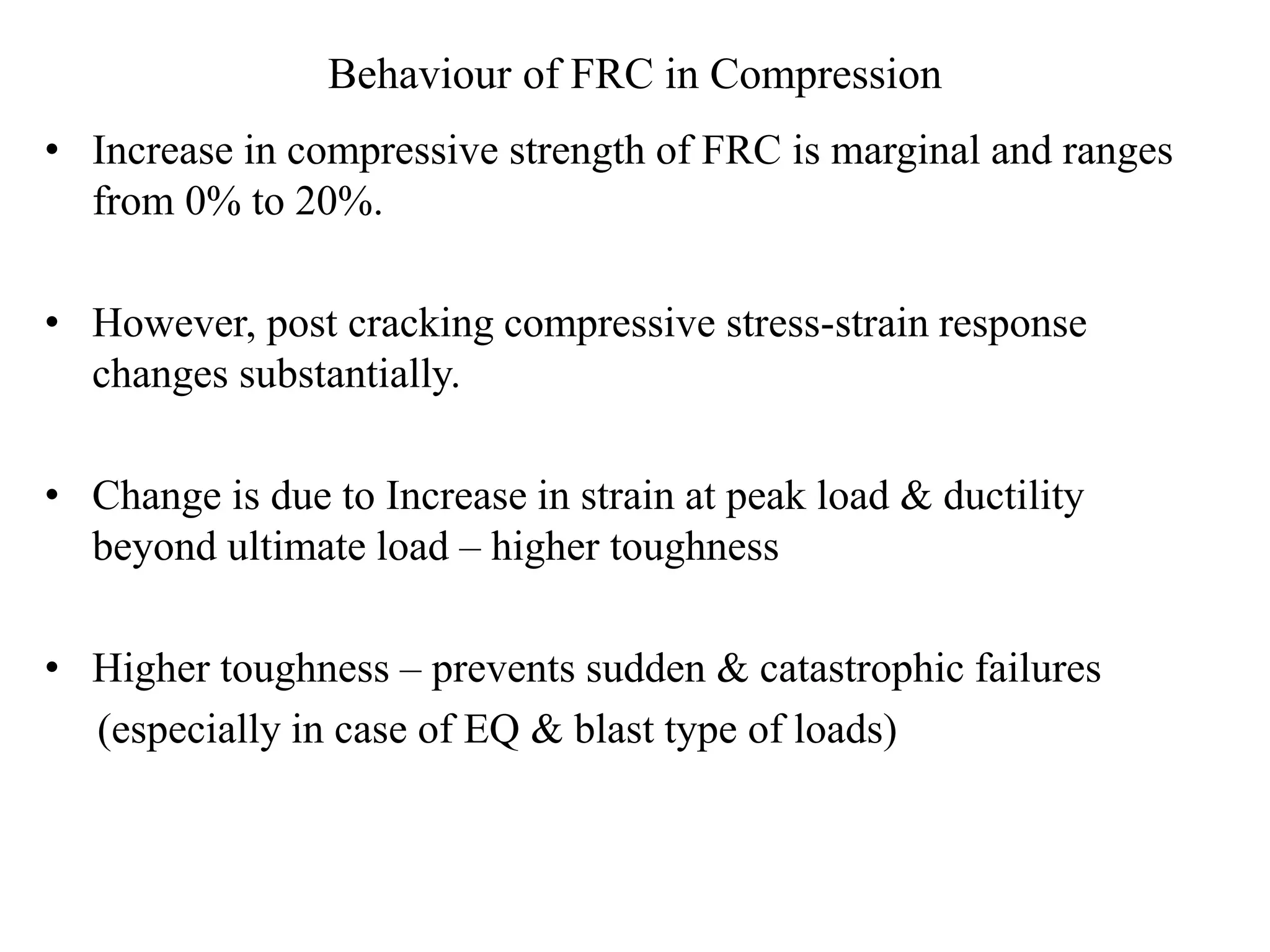

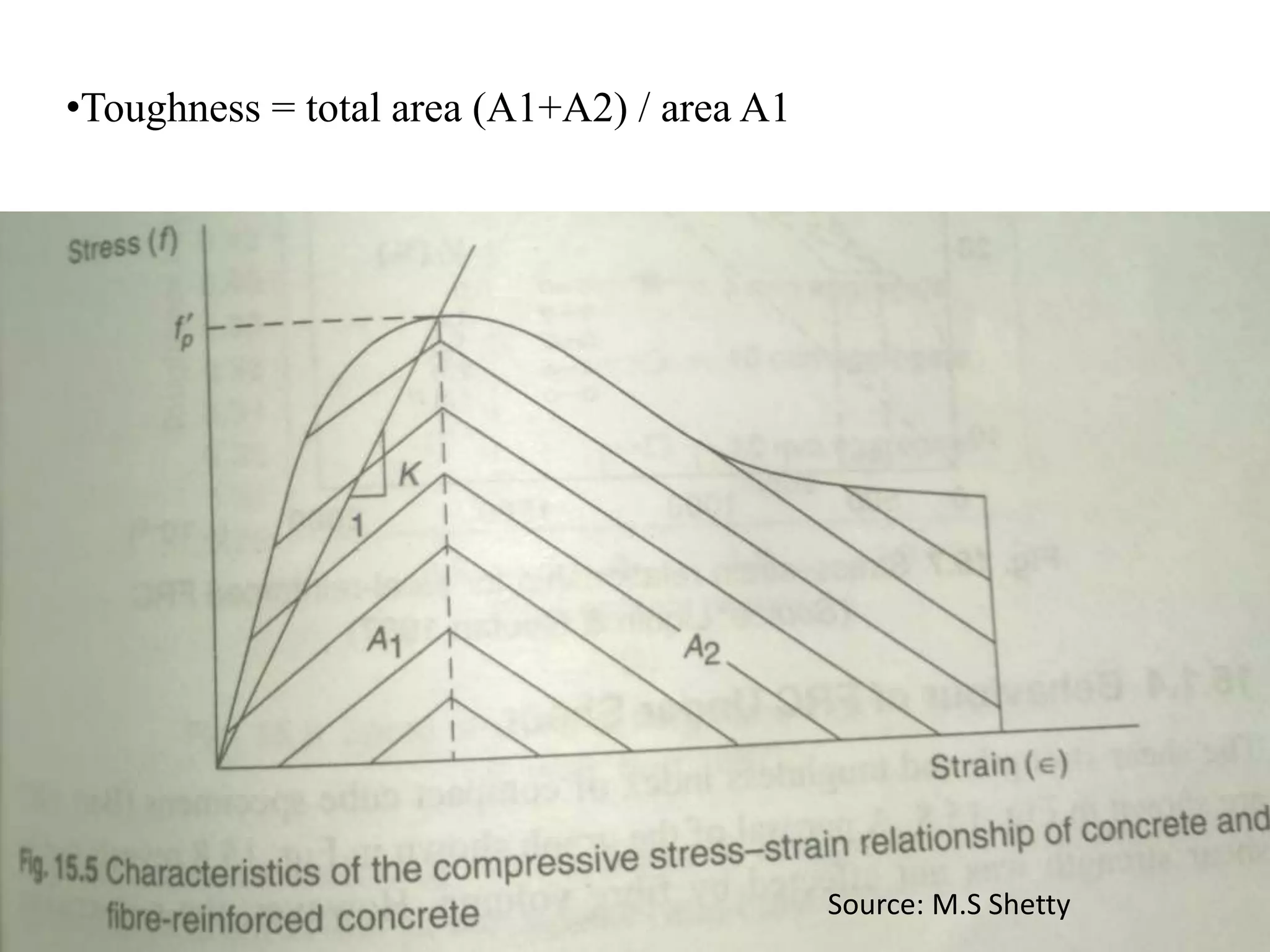

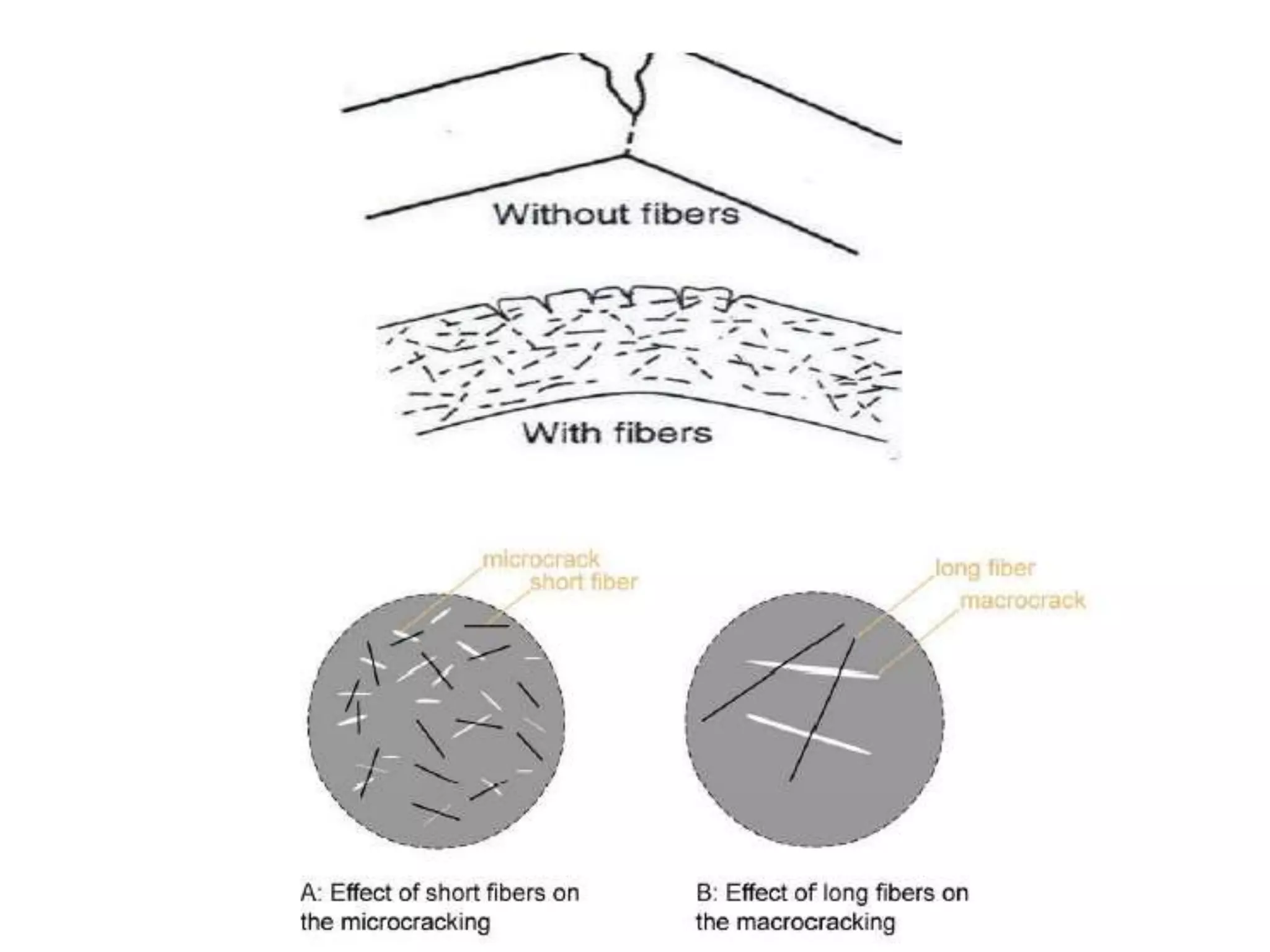

Fibre reinforced concrete is a type of concrete containing fibres that increase its structural integrity. It is made of Portland cement reinforced with randomly distributed fibres. The fibres are used to overcome concrete's weakness in tension and brittleness. Common fibre types include steel, glass, carbon and polypropylene. Factors like fibre volume, aspect ratio, orientation and relative stiffness affect FRC properties. FRC exhibits improved tensile cracking behaviour and increased toughness, energy absorption and fracture resistance compared to conventional concrete.