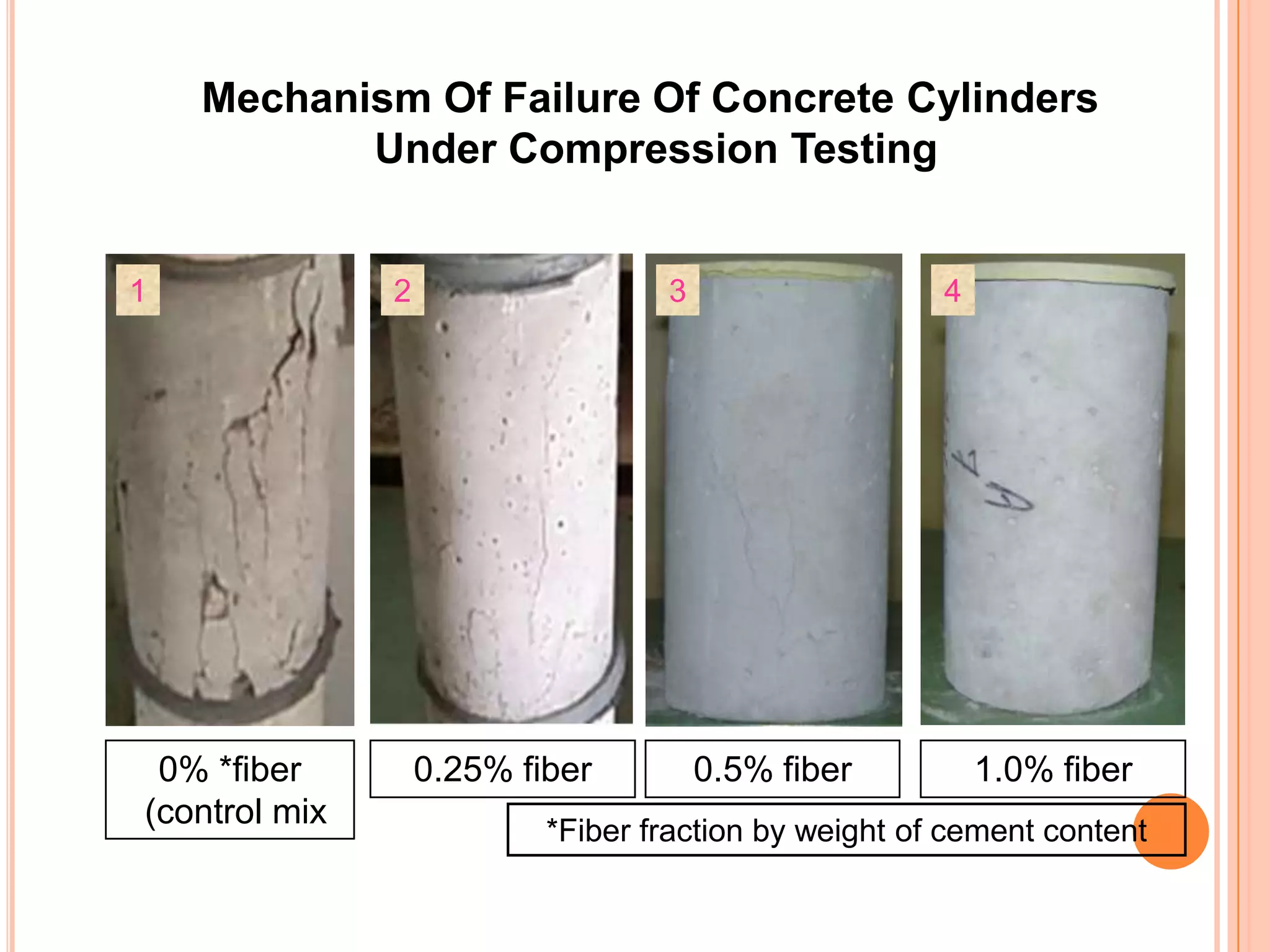

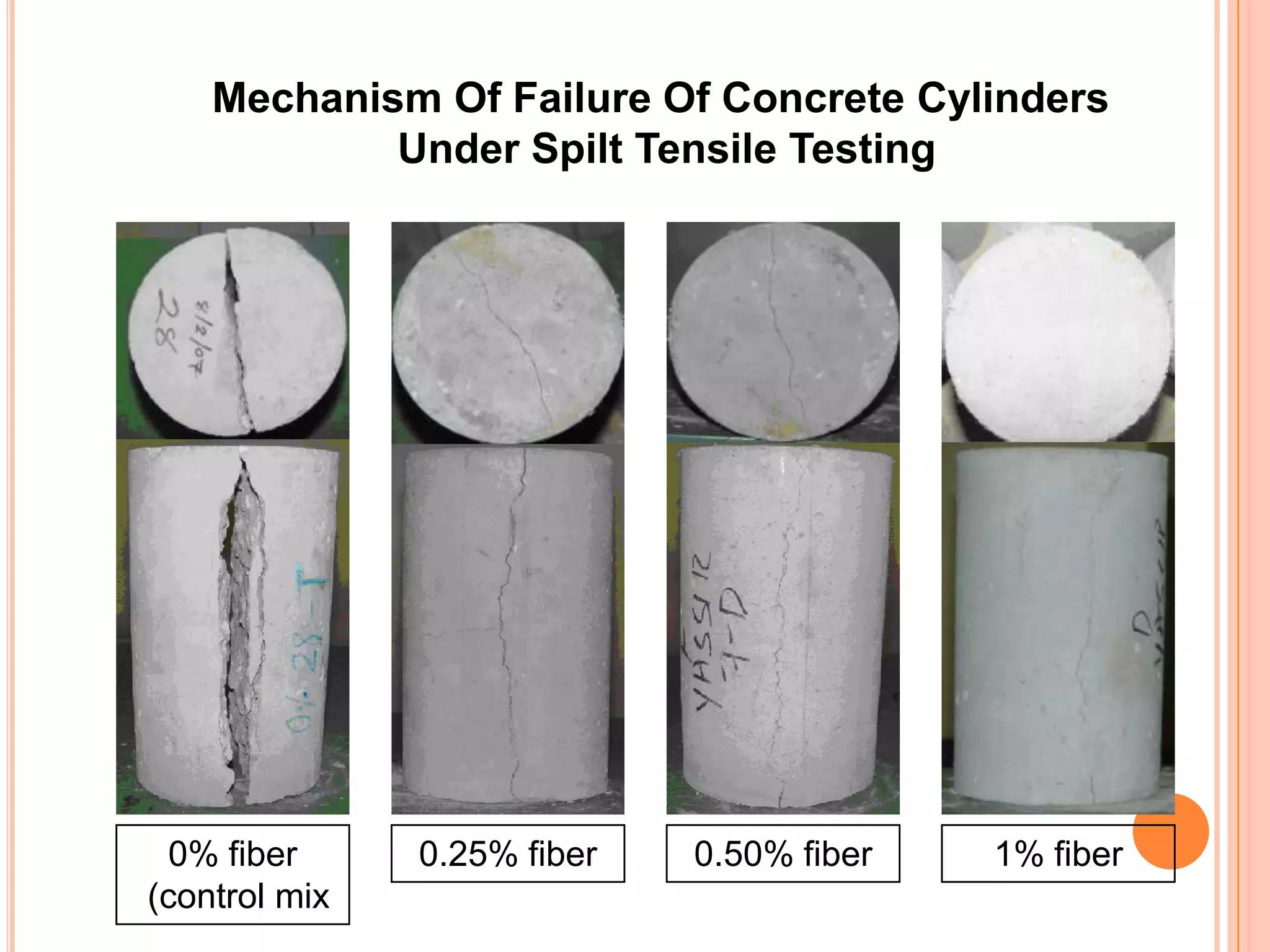

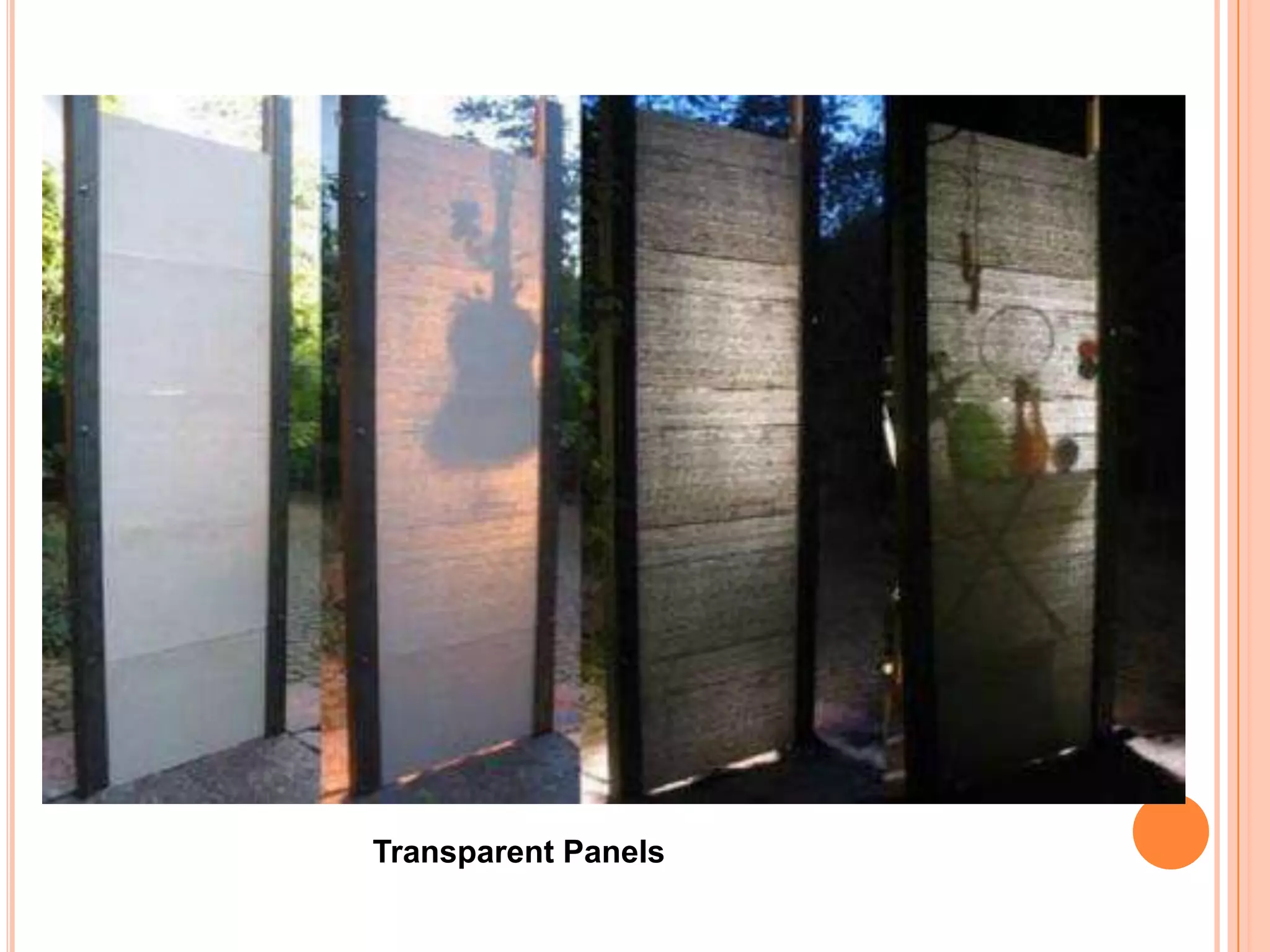

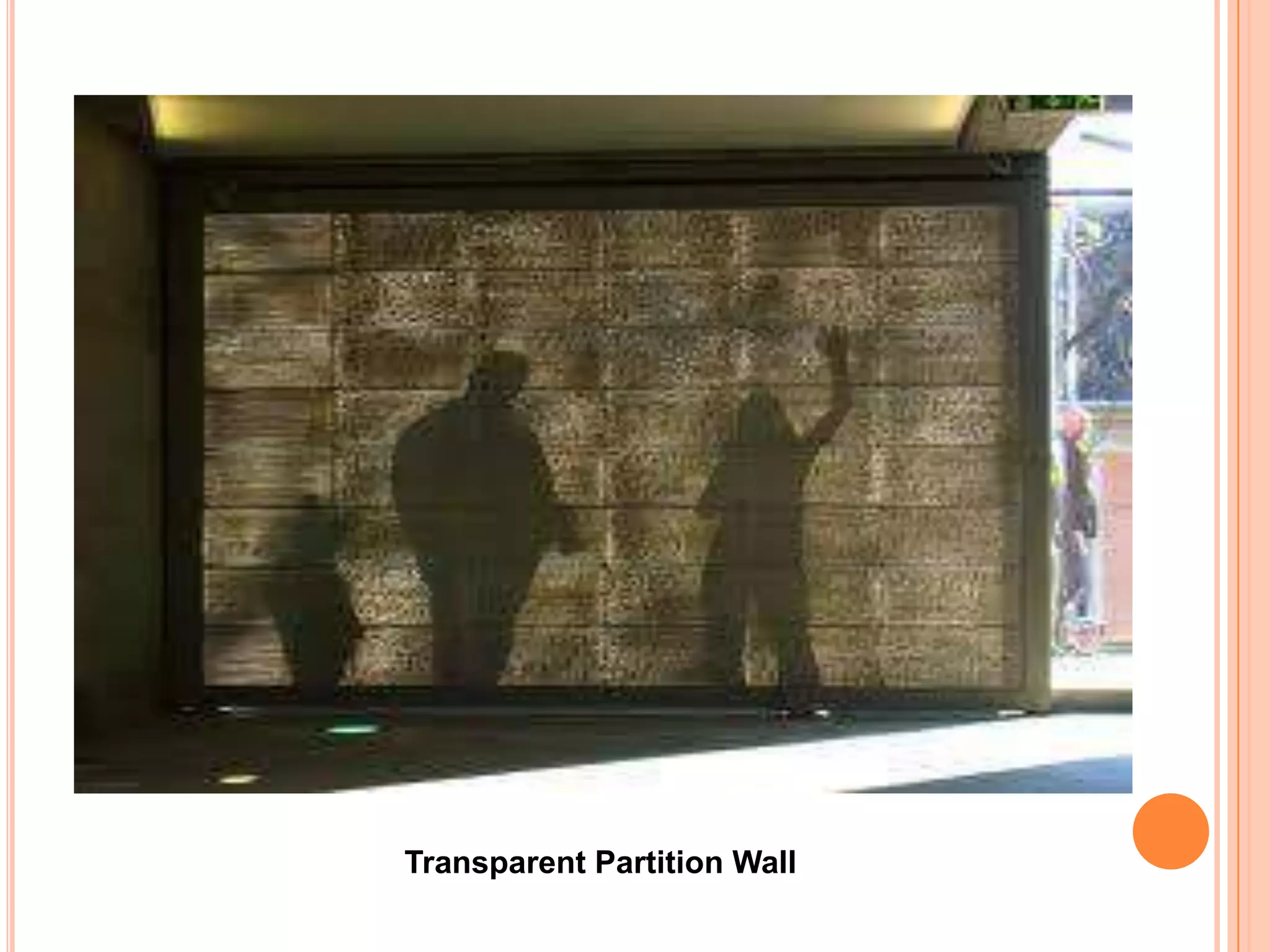

Ch. Gopi Chand presented on fiber reinforced concrete at Sri Venkateswara Engineering College. Fiber reinforced concrete was developed as a replacement for asbestos fibers in concrete. It involves adding short discrete fibers uniformly throughout a concrete mix. These fibers increase the tensile strength and cracking resistance of concrete. Fiber reinforced concrete has applications in thin sheets, pipes, precast elements, and transparent panels and partitions due to its improved strength and durability properties.