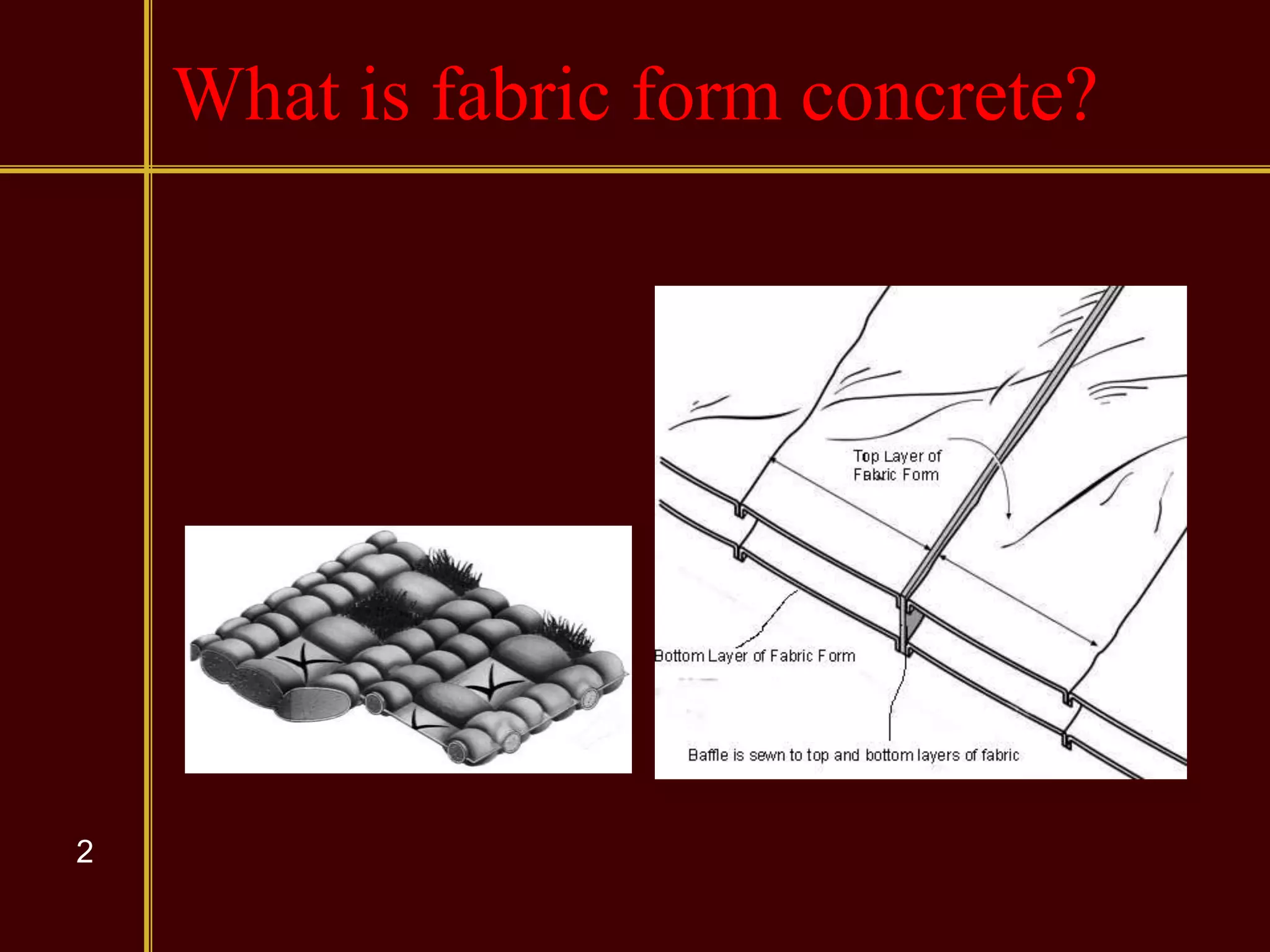

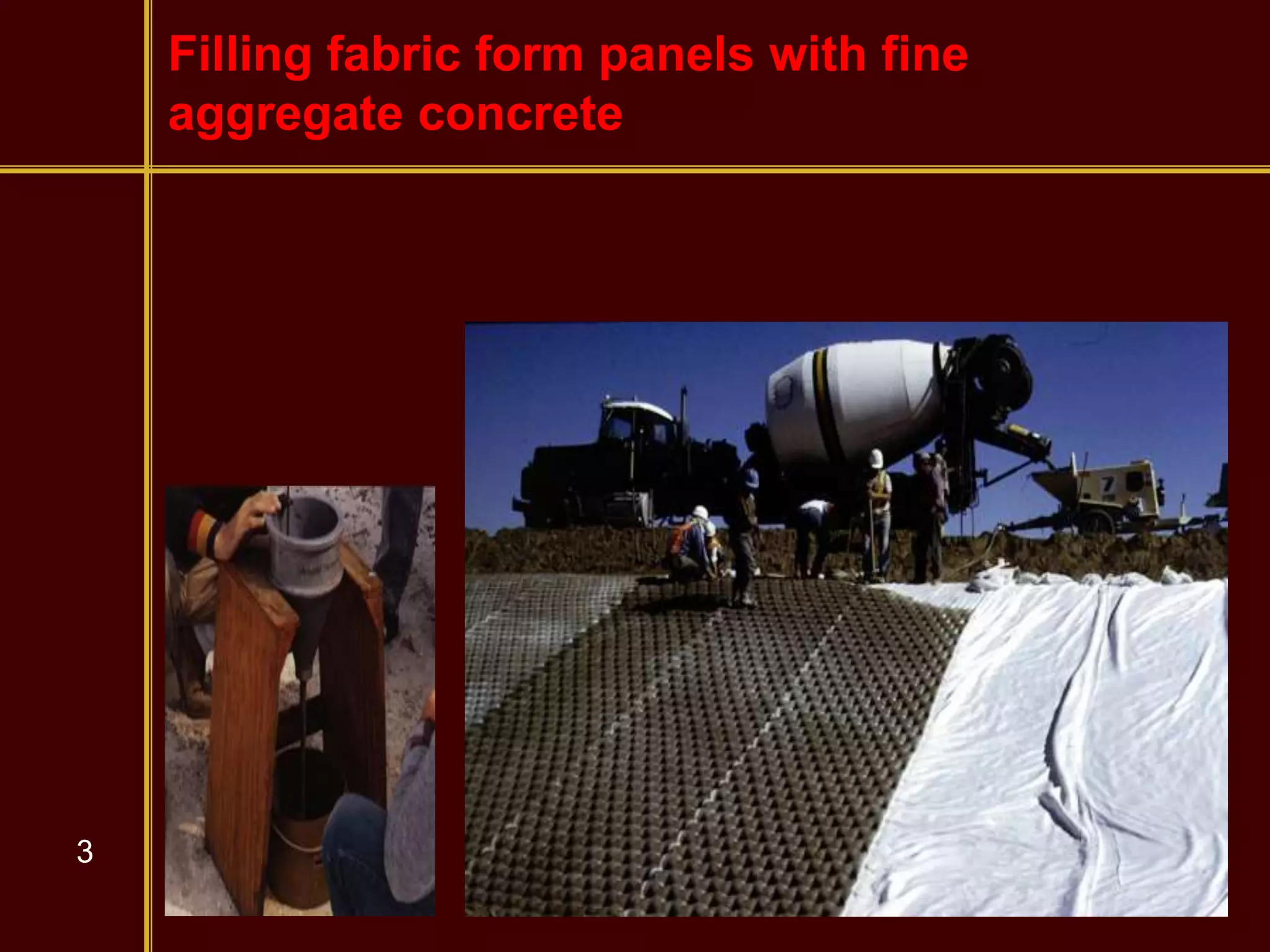

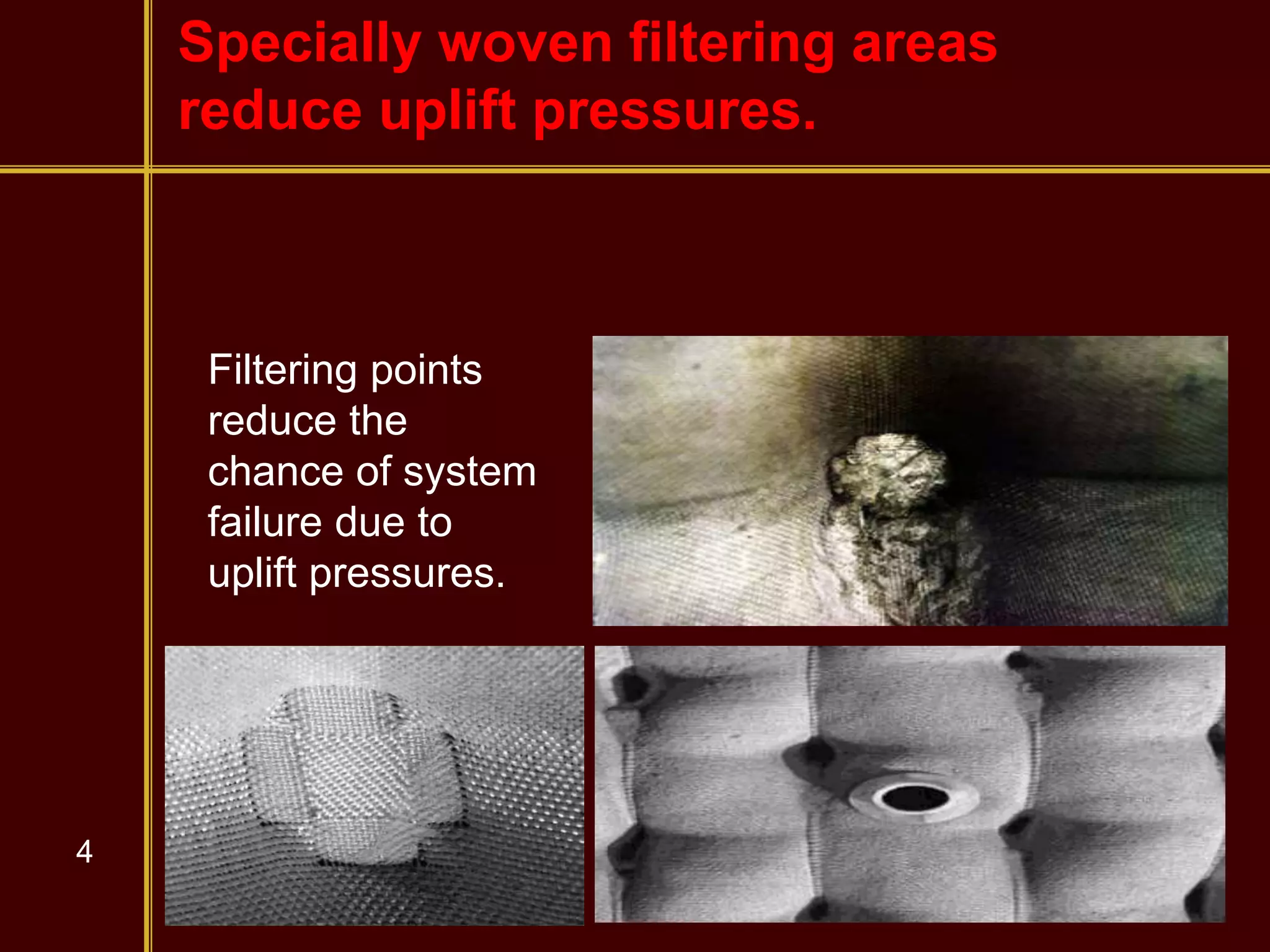

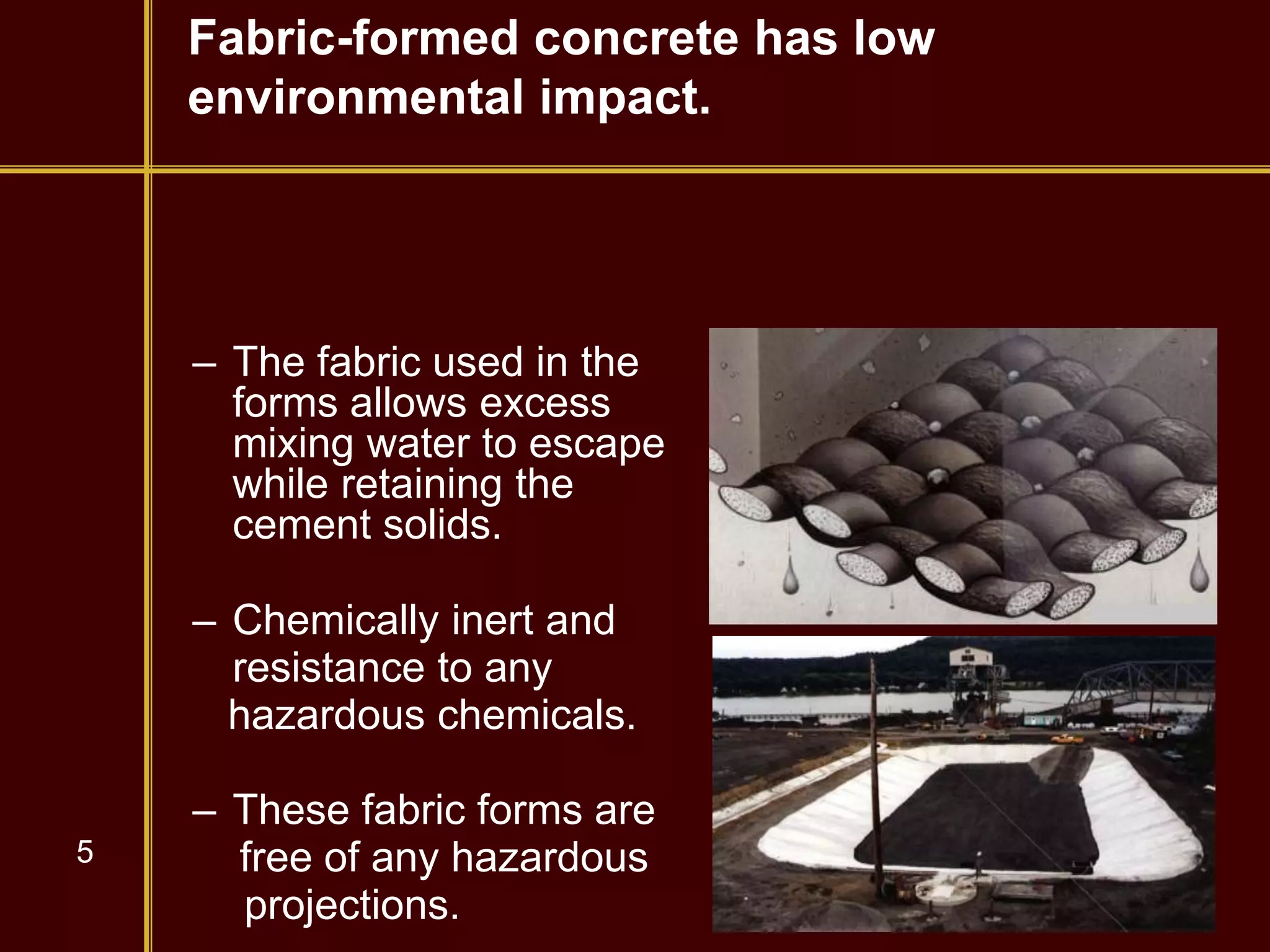

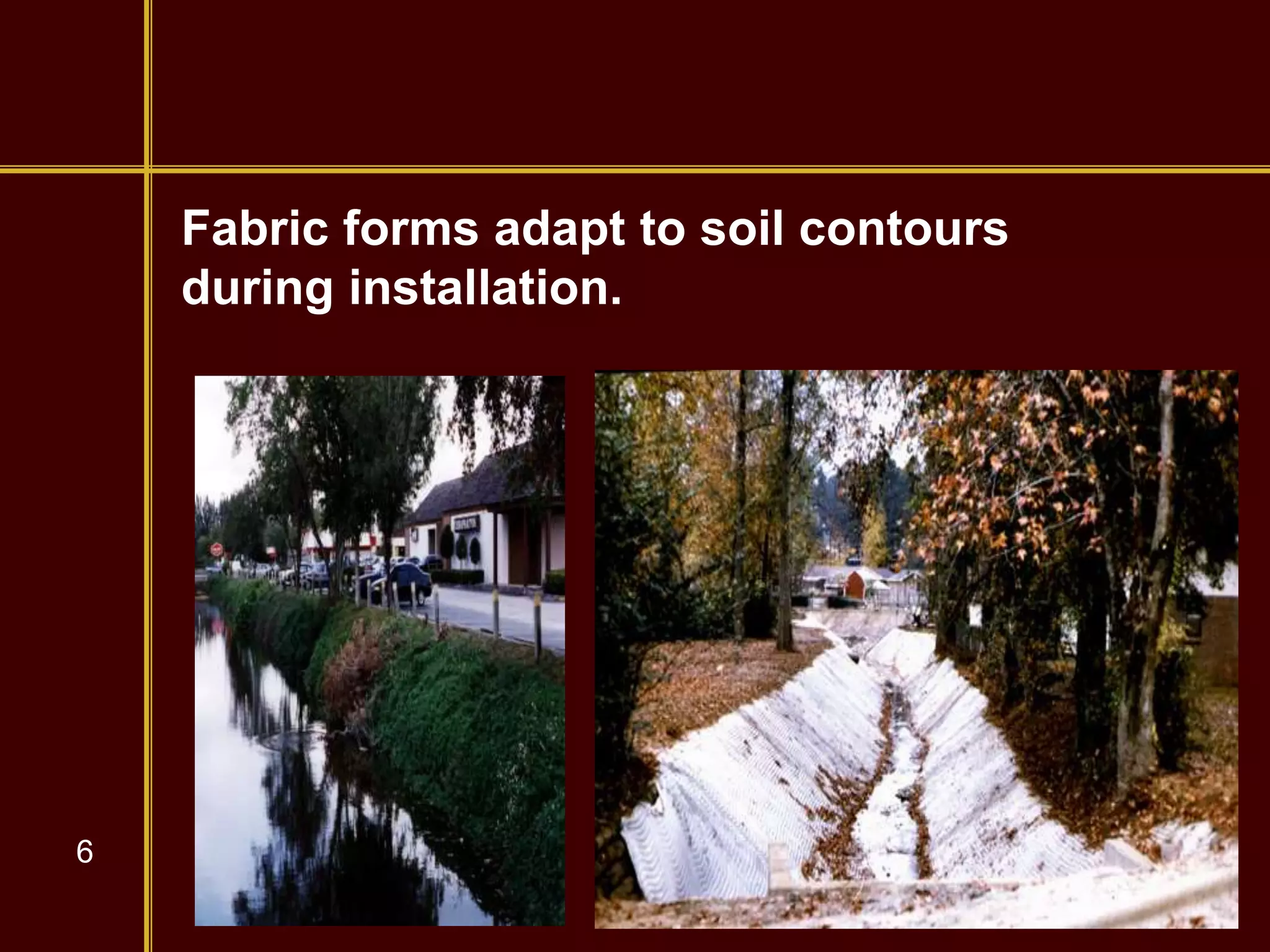

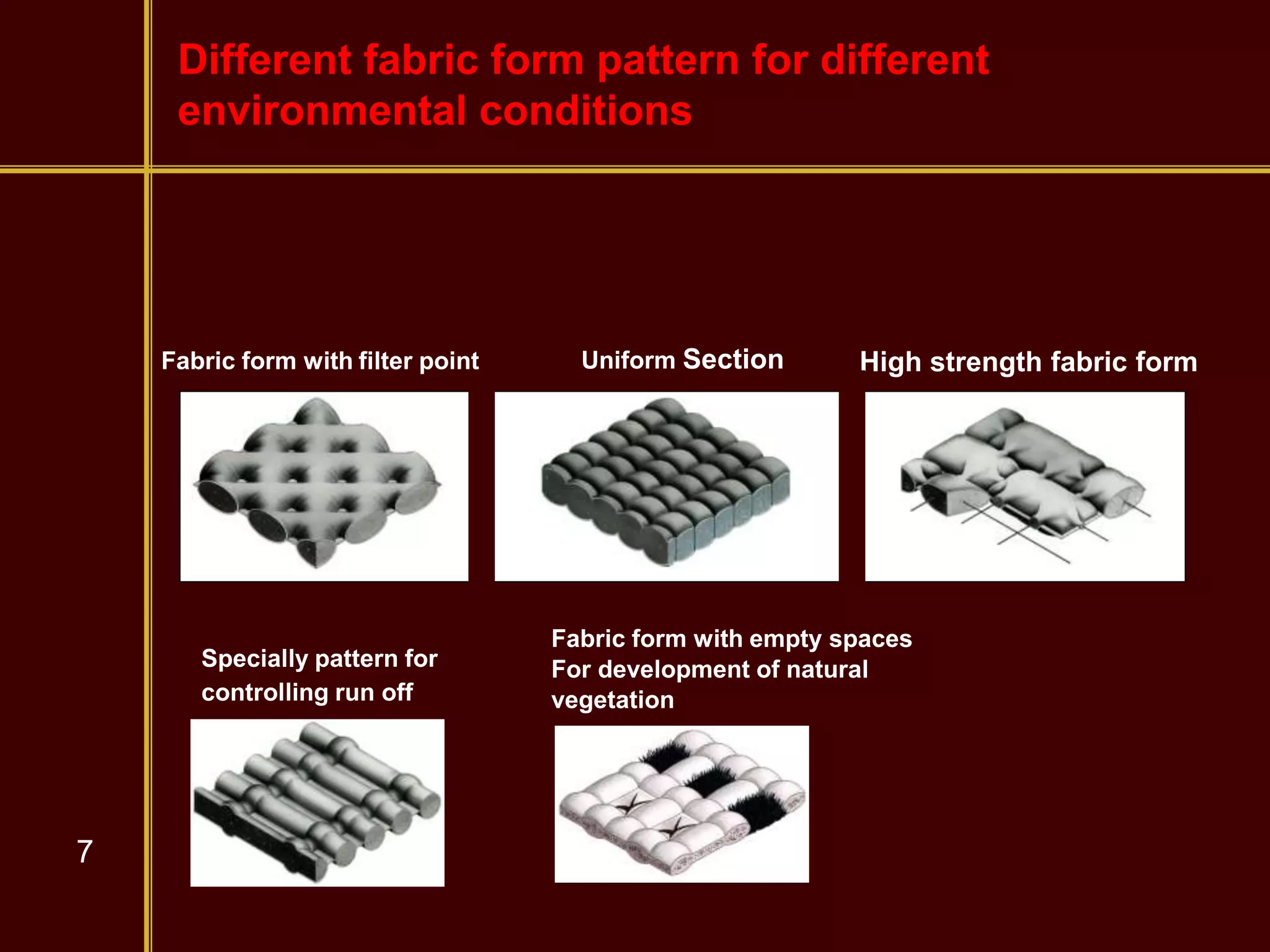

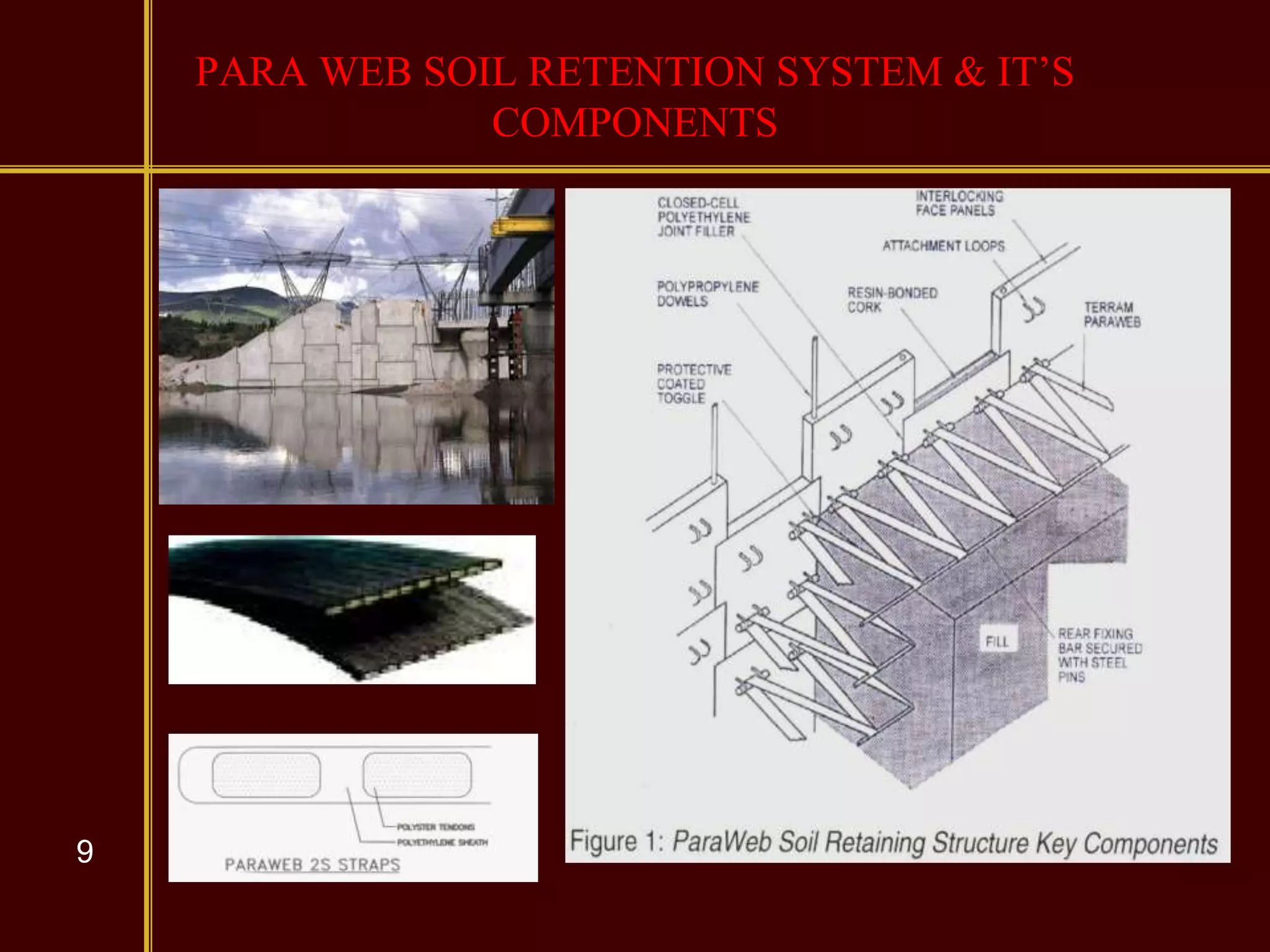

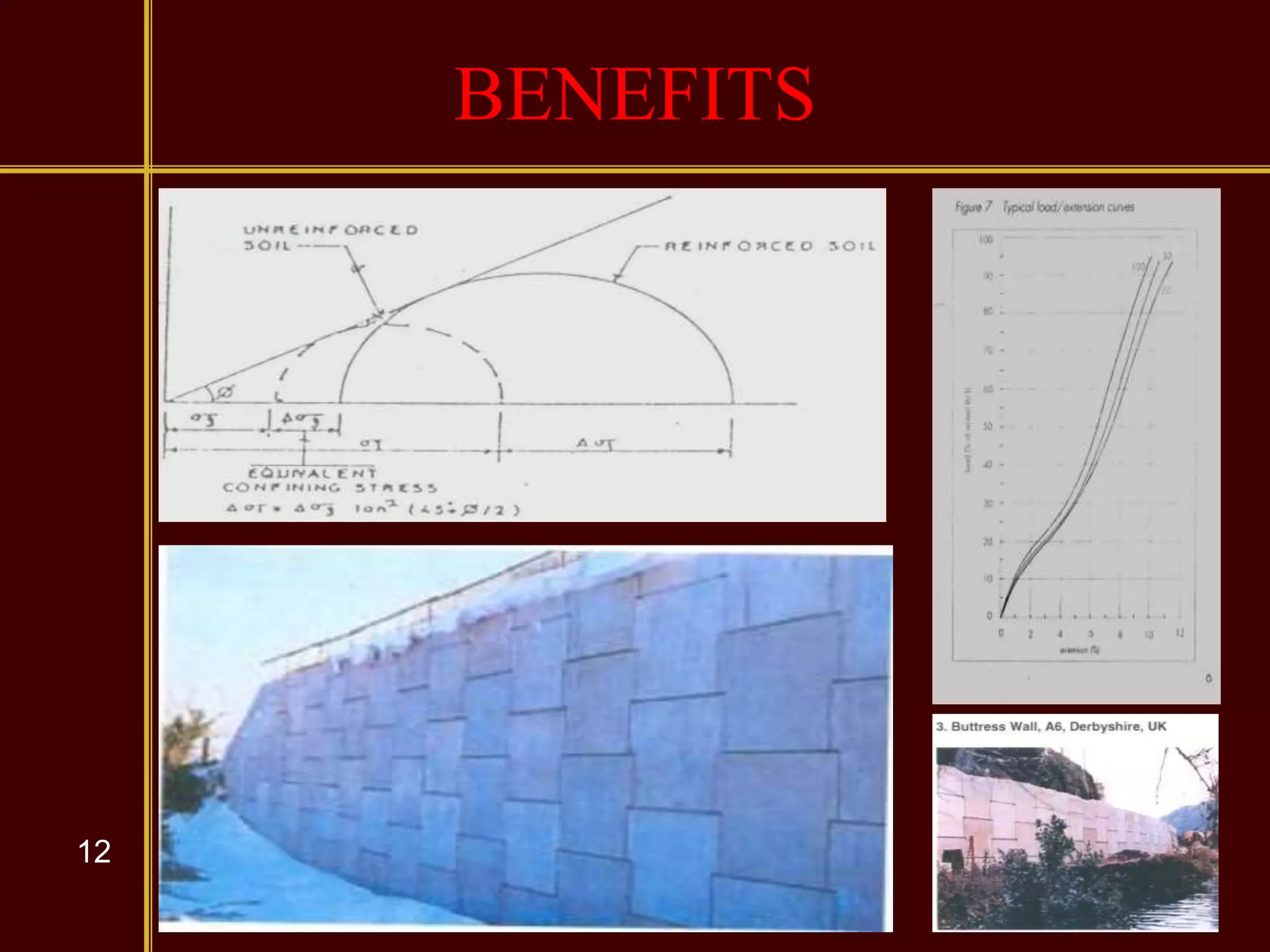

Fabric form concrete involves filling specially woven fabric panels with fine aggregate concrete to create structures that adapt to soil contours during installation. The fabric forms have filtering points that reduce uplift pressures and the chance of system failure. They allow excess water to escape while retaining cement solids, and are chemically inert and hazard-free. Para web soil retention systems use geo-textile fabrics and compacted soil fills for slope stabilization and erosion control.