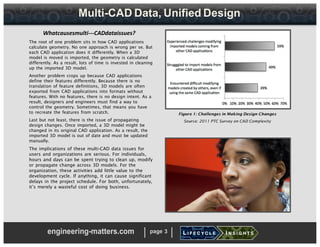

The document discusses the challenges of working with multi-CAD data, emphasizing productivity loss due to interoperability issues among different CAD applications. It highlights three recent technological advancements that improve collaboration: visualization tools for cleaner geometry imports, recognition of design intent in imported models, and automated updates to 3D models when original files change. These innovations aim to alleviate the inefficiencies of traditional CAD workflows and enhance the overall design process.