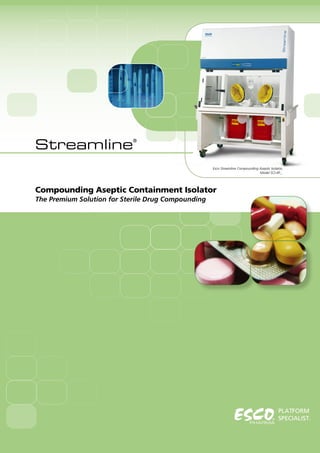

This document provides information about the Esco Streamline Compounding Aseptic Isolator. It describes the main features of the isolator including ULPA filters that provide superior air cleanliness, a gold microprocessor controller that monitors airflow and pressures, and positive pressure work zones. The document discusses the isolator's robust dual-wall construction, ergonomic design, and antimicrobial coating. It also summarizes the isolator's certification, filtration system, safety features, and options.