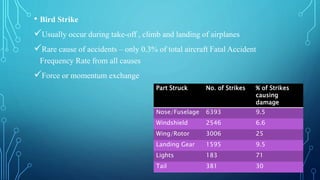

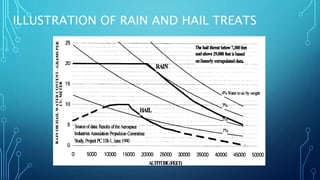

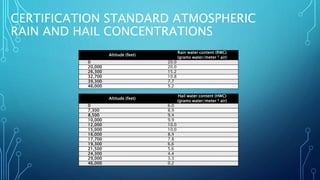

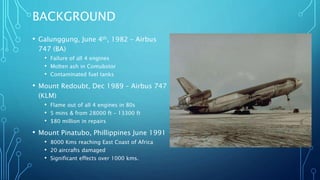

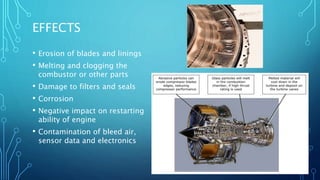

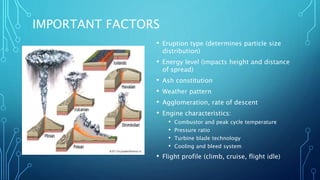

The document outlines engine ingestion standards and certifications mandated by the FAA concerning bird, hailstone, and volcanic ash ingestion tests. It specifies the requirements and methodologies for ensuring engine resilience against these threats during critical flight phases, detailing the impacts of each type of ingestion and corresponding safety measures and certification standards. Additionally, the document discusses challenges related to volcanic ash encounters and the need for improved forecasting and testing methods.