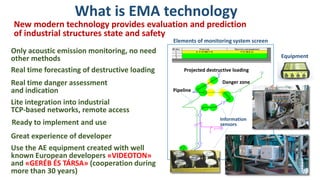

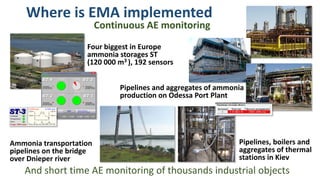

EMA technology offers acoustic emission monitoring for real-time evaluation and prediction of industrial structures' safety, eliminating the need for other methods. It has been successfully implemented in various large-scale projects, including ammonia storages and aerospace testing, demonstrating accurate forecasting of destructive loading. Future plans involve improving technologies, developing regulatory documentation, and commercialization efforts in continuous monitoring systems.