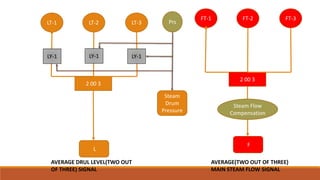

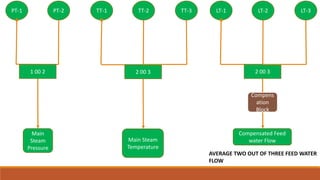

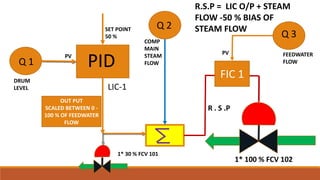

This document describes the closed loop control system used for boiler drum level control. It uses a three element control approach with drum level, feedwater flow, and main steam flow as process variables. During startup, a single 30% capacity feedwater control valve (FCV-101) is used to maintain drum level setpoint. At 30% load, control switches to two 100% capacity main feedwater valves (FCV-102) controlled via a three element algorithm. Drum level is measured by three level transmitters and averaged for input to the level controller (LIC-101). The controller output is summed with steam flow and used to set the remote setpoint for FIC-101, which controls FCV-102 position