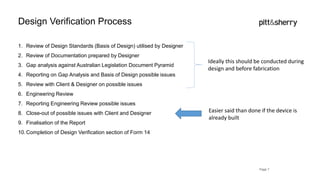

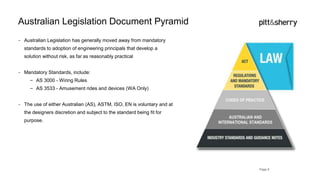

The document outlines the design registration process for amusement devices under Australian regulations, emphasizing the importance of verifying designs to ensure they meet technical standards before supply. It details who is involved in the process, including the applicant, designer, and design verifier, and highlights the role of the verifier in reviewing documentation and compliance with standards. The document also recommends initiating verification early in the design phase to identify and resolve issues efficiently.