The document presents a proposed system for human detection and rescue operations during disasters using a mobile rescue robot. The system consists of two main units:

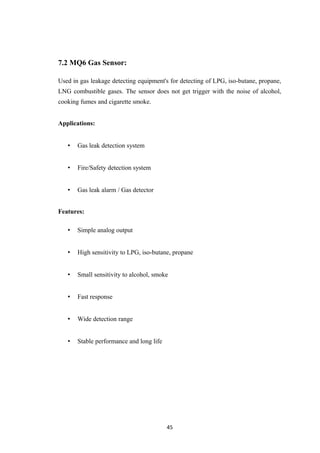

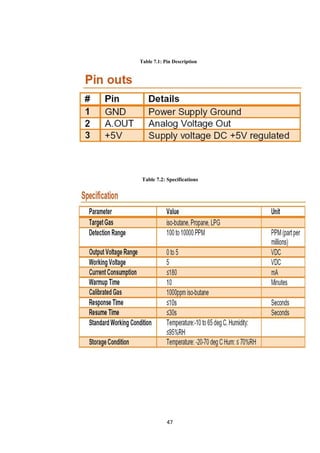

1) A robot unit comprising sensors like PIR, gas and temperature sensors, a wireless camera, and a ZigBee module for wireless communication. It is controlled by an Arduino microcontroller.

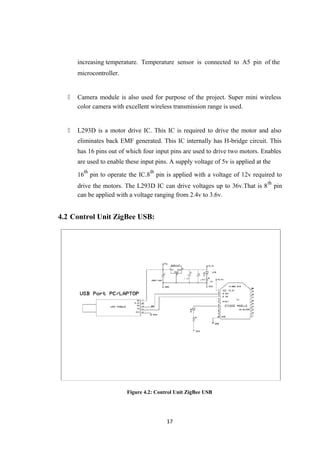

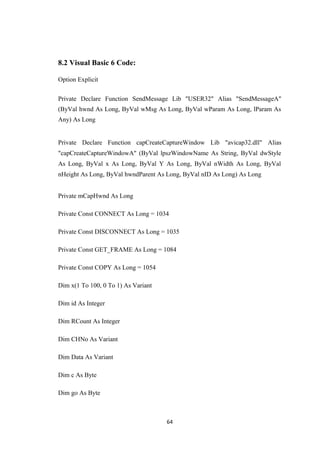

2) A control unit with a ZigBee USB module for communicating with the robot unit. It allows an operator to manually control and monitor the robot.

The system is designed to allow the robot to autonomously detect trapped humans using its onboard sensors, and transmit the location and sensor data back to the control unit to facilitate rescue operations. The overall

![Another static trait is the involuntary motion of internal organs, such as the heart and

lungs. This can be measured through skin-penetrating radio and ultrasound signals.

Finally, a relatively new avenue for human-sensing lies in scent detection [Pearce et

al. 2006].

Furthermore, CO2 levels have also been used to detect the presence of people, albeit

with slow response times [De Cubber and Marton 2009].

Dynamic traits are those that arise from human activity. We divide these into three

categories: external motion, gait, and vibrations. As for vibrations, these are the

pressure waves that people produce either involuntarily (in the form of sounds and

vibrations from footsteps, for example) or voluntarily (in the form of speech), which

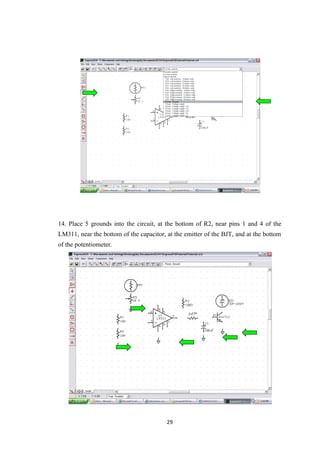

can be measured with accelerometers and microphones, respectively.

2.2 Sensor classification:

On basis of many different human traits that can be used for identifying human

presence large no. of sensors are available. Of which we limit ourselves to a selection

of approaches which are either the most useful, the most ubiquitous, or the most

ingenious. We discuss these in the context of similar solutions to illustrate the

advantages and disadvantages of each.

Binary Sensors:

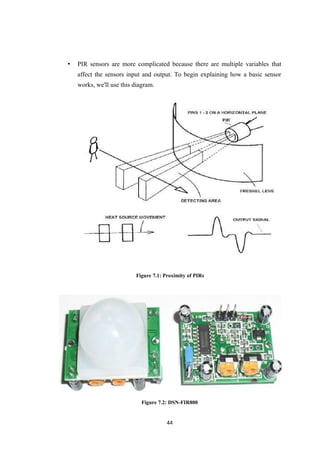

A variety of sensing modalities can be grouped into the broad category of “binary

sensors". In the context of human-sensing, binary sensors are those that return logic 1

if human presence is detected within a certain sensing area, otherwise returning logic

0. The modality of binary sensors includes sensors such as break-beams, contact

sensors, PIRs, and binary Doppler-shift sensors, all of which are currently used in

resource-constrained scenarios. In single-node configuration, binary sensors can only

be used to detect presence, and nothing more.

4](https://image.slidesharecdn.com/19e5fc7d-ed29-4b62-8a3a-4463903a6082-161217232126/85/Degree-Project-12-320.jpg)

![REFERENCES

THIAGO TEIXEIRA Yale University, GERSHON DUBLON Massachusetts

Institute of Technology and ANDREAS SAVVIDES Yale University-“A

Survey of Human-Sensing:

Methods for Detecting Presence, Count, Location, Track, and

Identity” ACM Computing Surveys, Vol. V, No. N, 20YY.

Geetha Bharathi.V.S PG Student, Department of ECE, Easwari Engineering

College, Chennai, TN, India , Dr.S.Sudha Professor, Department of ECE,

Easwari Engineering College, Chennai, TN, India-“Alive Human Detection in

Disaster Zones using Manually Controlled Robots”

IJIRCCE Vol. 3, Special Issue 2, March 2015.

Trupti B. Bhondve PG student[VLSI], Dept. of E&TC , Dr.D.Y.Patil College

of Engineering, University of Pune, Ambi, Pune, India, Prof.R.Satyanarayan

Assistant Professor, Dept. of E&TC , Dr.D.Y.Patil College of Engineering,

University of Pune, Ambi, Pune, India, Prof. Moresh Mukhedkar Assistant

Professor, Dept. of E&TC , Dr.D.Y.Patil College of Engineering, University

of Pune, Ambi, Pune, India-“Mobile Rescue Robot for Human Body

Detection in Rescue Operation of Disaster”

IJIRCCE Vol. 3, Issue 6, June 2014.

Rajeev Joshi *, Pratap Chandra Poudel **, Pankaj Bhandari Department of

Electronics & Communication, N.I.T, Raichur, Karnataka, India-“An

Embedded Autonomous Robotic System for Alive Human Body Detection

and Rescue Operation”

International Journal of Scientific and Research Publications, Volume 4, Issue

5, May 2014

Basic Electronics – B.Ram

Digital Electronics – R.P.Jain

74](https://image.slidesharecdn.com/19e5fc7d-ed29-4b62-8a3a-4463903a6082-161217232126/85/Degree-Project-83-320.jpg)