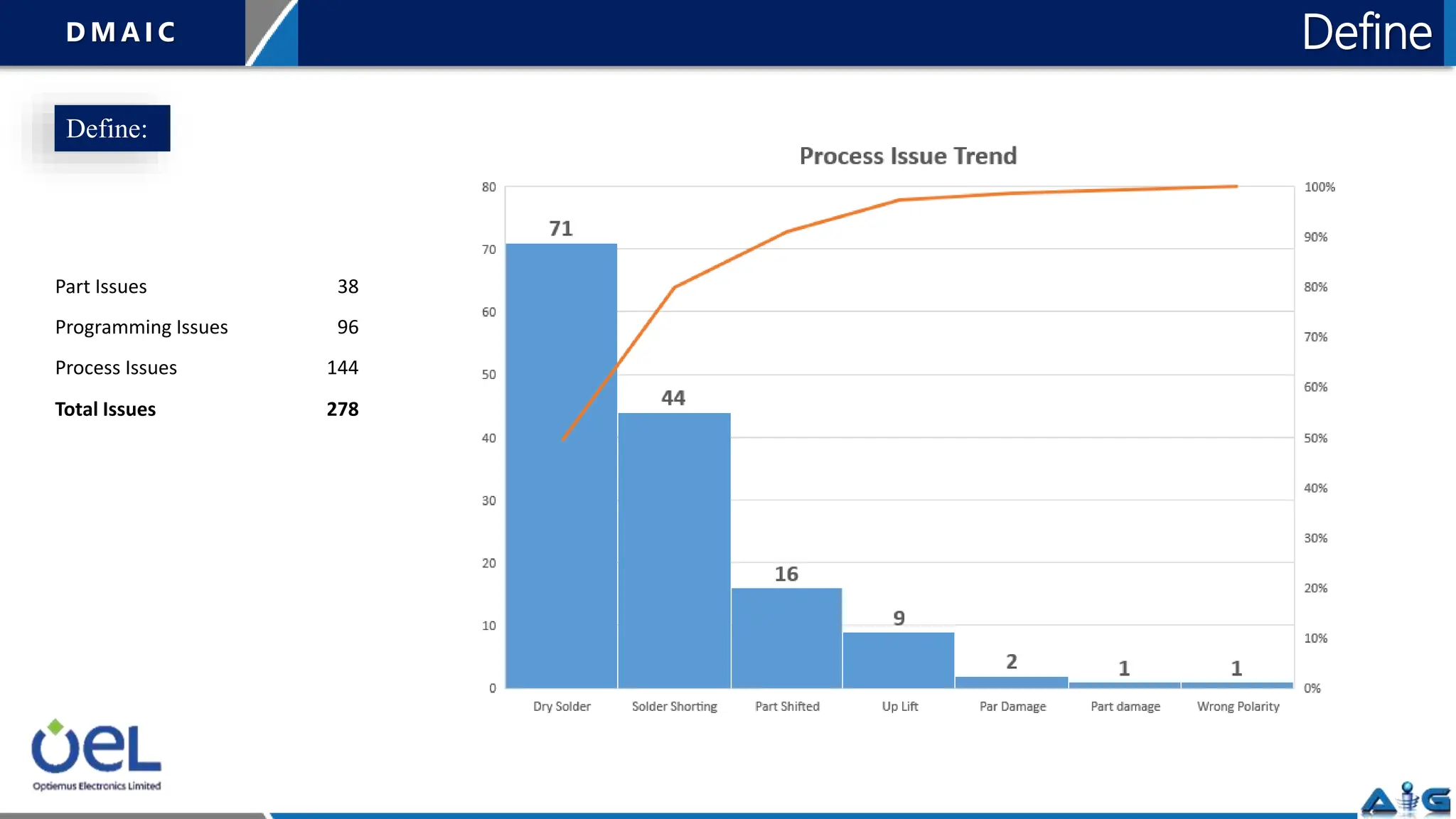

The defect reduction project for the Tejas RAC model aims to address a 19% failure rate during testing, primarily due to soldering issues that account for 60% of defects. The project's goals include reducing these defects to improve yield, decrease wastage, and minimize rework costs. A team is structured with specific roles, and a detailed project plan is outlined to follow DMAIC phases over the course of several weeks.