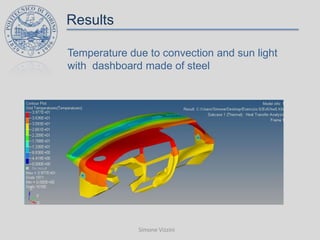

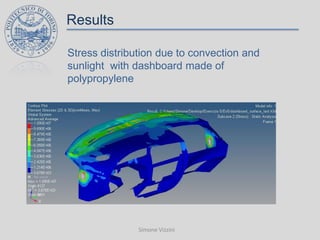

The document describes a study of the temperature distribution and structural deformation of a dashboard surface subjected to direct sunlight. The study involves creating models of the dashboard made of polypropylene and steel in Abaqus. Both materials are subjected to convection heating from the vehicle interior and a 400 W/m2 heat flux to simulate sunlight. The results show that while steel distributes heat more uniformly, polypropylene reaches lower maximum temperatures. Both materials experience strain from the thermal loading, but steel exhibits lower displacement and higher stresses at constraint points due to its higher modulus of elasticity. However, using steel for a 2.5mm thick dashboard would compromise flexibility.

![Description of the problem

Material

used:

Polypropylene

E [Gpa]

ν

1.8

0.45

ρ

[kg/m3]

946

Thermal

Expansion

coefficient [1/C°]

Thermal

Conductivity

[W/mC°]

Heat

Transfer

coefficient [W/m2C°]

150 e-6

0.16

25.4

73

40

Steel

210

0.3

7800

1 e-5

Dashboard property:

– thickness t= 2.5 mm

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-3-320.jpg)

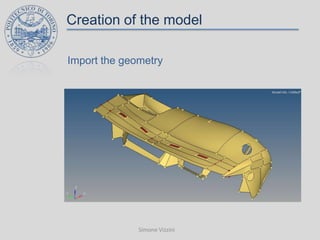

![Creation of the model

Move some surface from dashboard to air tunnel

– [tool-organize]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-6-320.jpg)

![Creation of the model

Create the Material and insert the specific

properties

– [card image:MAT1 and MAT4 for thermal properties]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-7-320.jpg)

![Creation of the model

Create the “Properties” and assign to the

components

• [card image:PSHELL, choose the material and define

the thickness]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-8-320.jpg)

![Creation of the model

Create the mesh and merging the common

nodes

– [2D-automesh, tool-edges]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-9-320.jpg)

![Creation of the model

Create the constraint point

– create the master nodes [geom-nodes]

– connect to the dashboard [1D-rigids]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-10-320.jpg)

![Creation of the model

Create the convection heat exchange surface

– [analysis-interfaces]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-11-320.jpg)

![Creation of the model

Create the internal heat source, creating a

constraint node with the specific initial T and

assign to to the dashboard

– [geom-node, analysis-constraint, card edit-insert the

inner T ]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-12-320.jpg)

![Creation of the model

Constraint all the air-tunnel nodes and assign

the initial T

– [analysis-constraints, card edit-insert the T ]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-13-320.jpg)

![Creation of the model

Create the conduction heat exchange surface,

create the flux, update the loadstep adding the

flux to the laod and Simulate

– [analysis-interfaces]

– [analysis-flux]

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-15-320.jpg)

![Creation of the model

Create the constraints for the master nodes.

– [analysis-constraints]

Create a generic load-step for the thermal stress

Simulate

Simone Vizzini](https://image.slidesharecdn.com/dashboard-131213030803-phpapp01/85/Dashboard-Thermal-Analysis-with-HyperWorks-16-320.jpg)