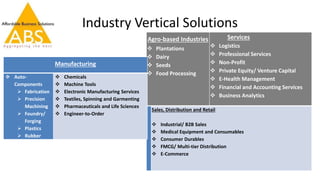

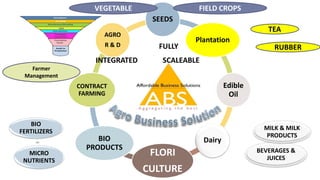

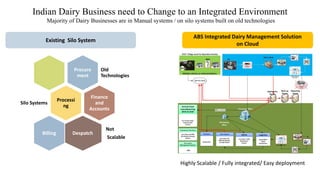

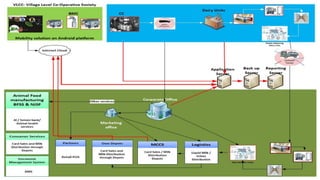

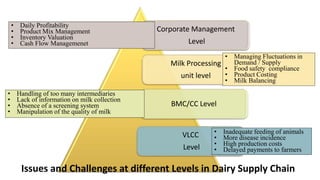

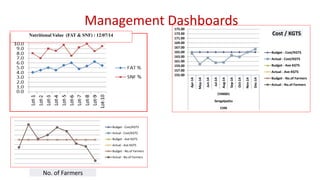

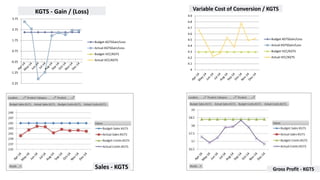

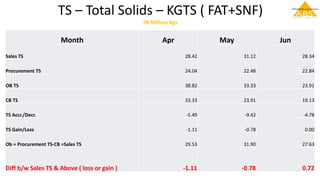

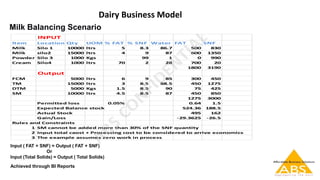

This document discusses using cloud technology for dairy businesses. It provides an overview of ABS, a company that offers industry vertical solutions including for agro-based industries like dairy. It outlines the key challenges dairy businesses face at different levels from procurement to processing to finance. It then describes the dairy industry business analytics and management dashboards ABS provides using cloud, including for milk balancing, daily profitability, and key performance indicators. Finally, it presents ABS's business model of minimal capital expenditure and quarterly subscription payments from customers.