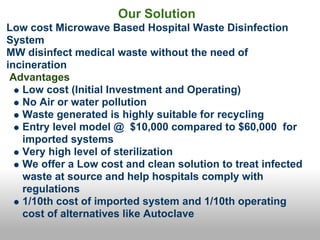

Microwave Based Biomedical Waste Disinfection System provides a low-cost solution to treat infected medical waste. It uses microwave technology to disinfect waste at the source for 1/10th the cost of imported autoclave systems with no air or water pollution. The market size for biomedical waste disinfection in India is estimated at $200 million, with 45,000 hospitals currently lacking treatment facilities. Cusen Systems plans to sell their $10,000 microwave systems directly to hospitals and develop a business providing waste management services. Their technology has been validated by industry experts and they are finalists for government grant programs to commercialize their prototype.