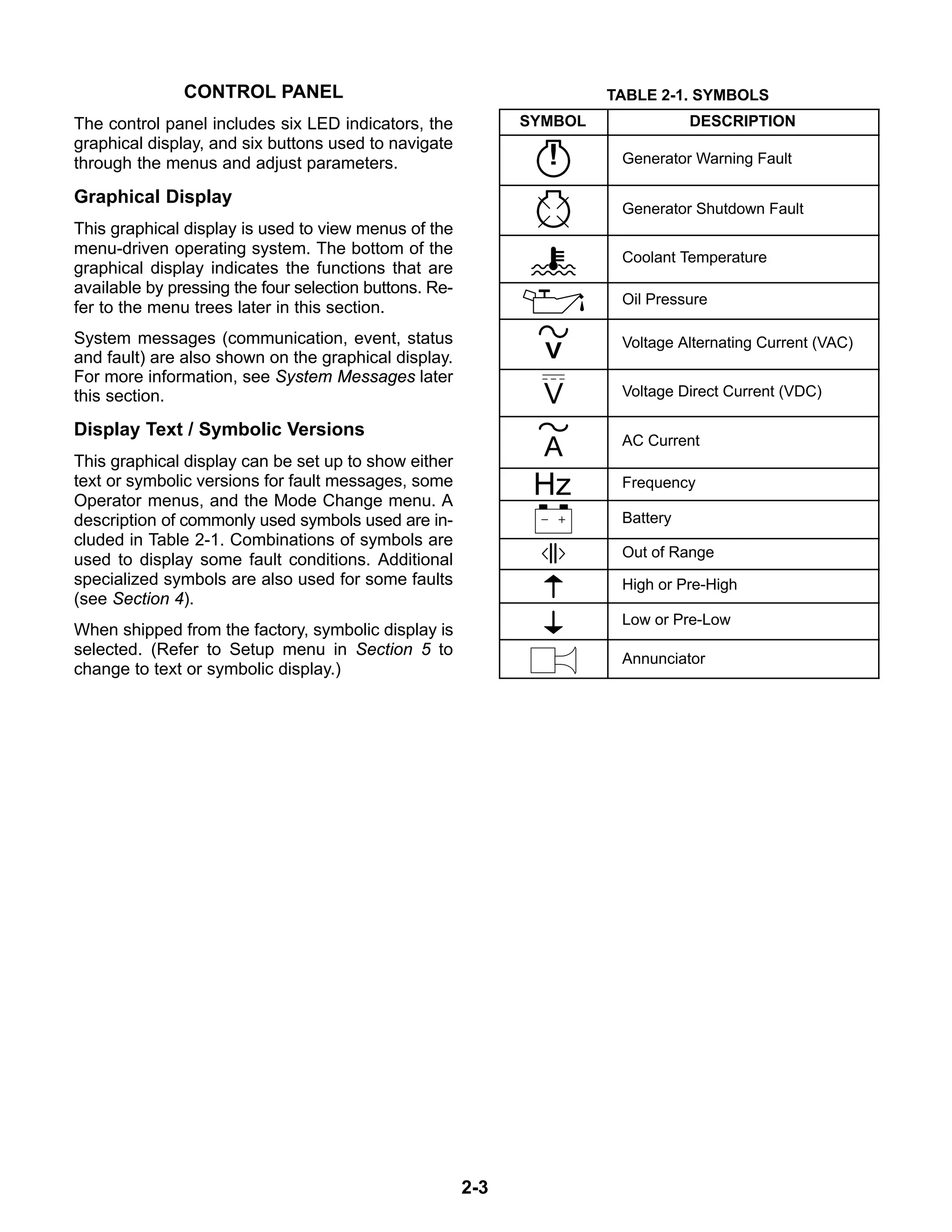

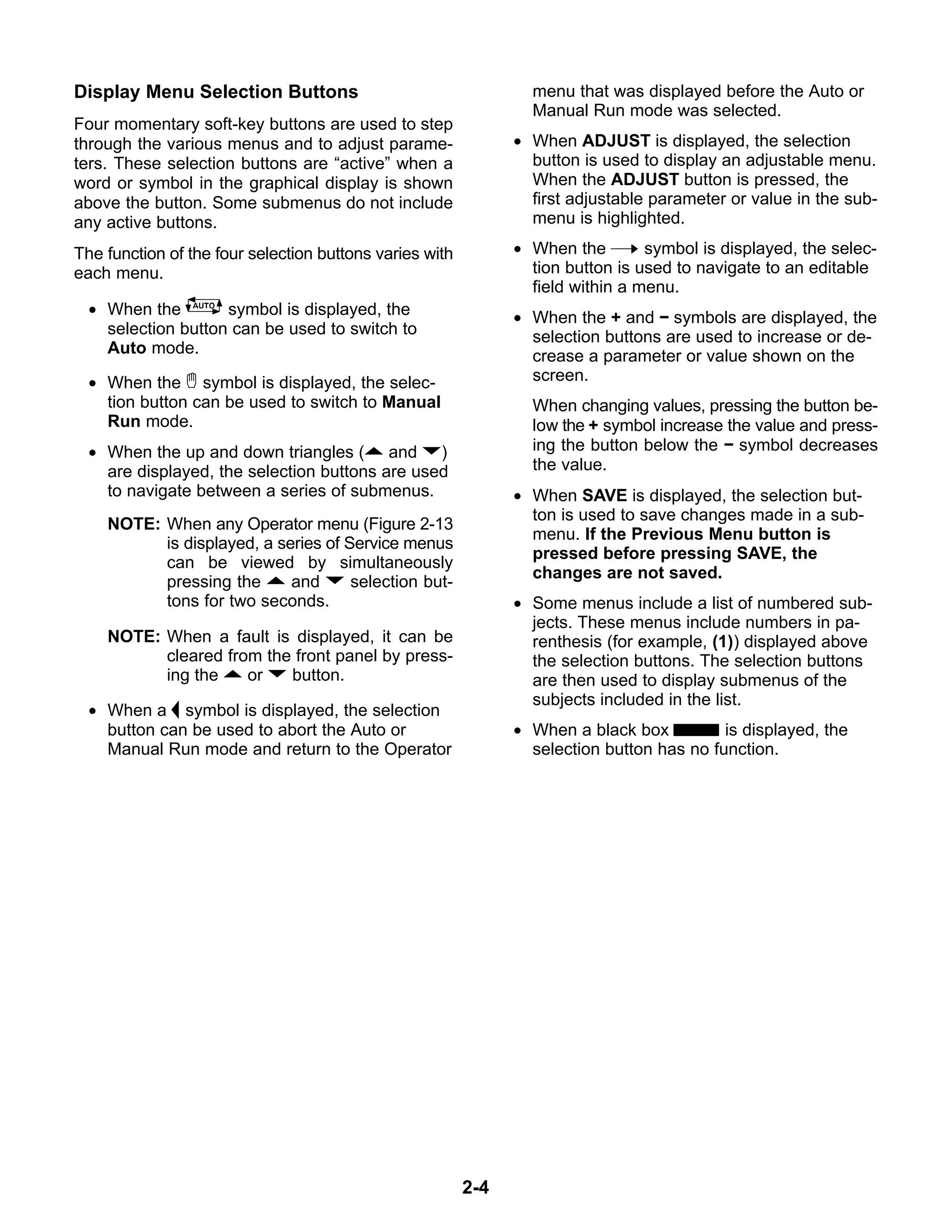

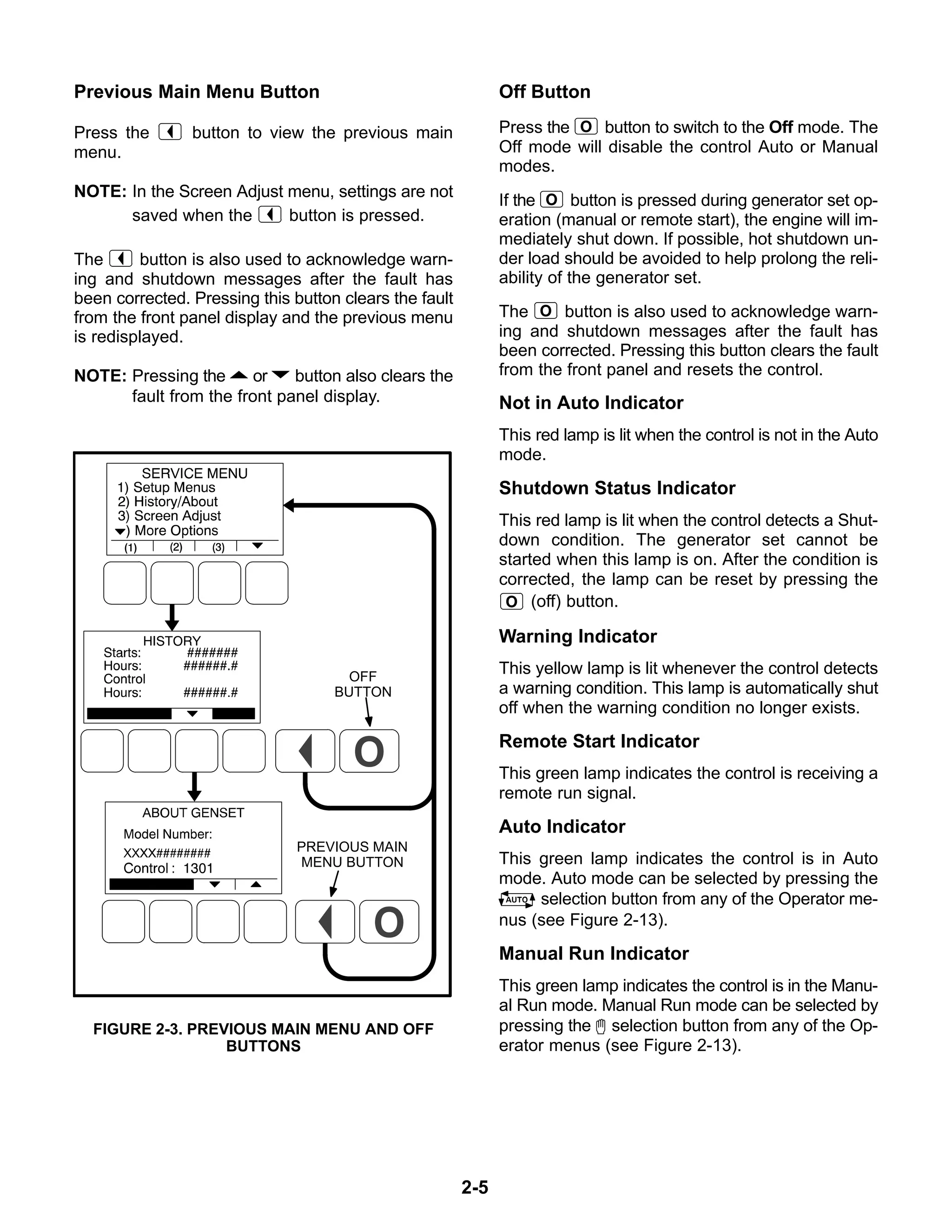

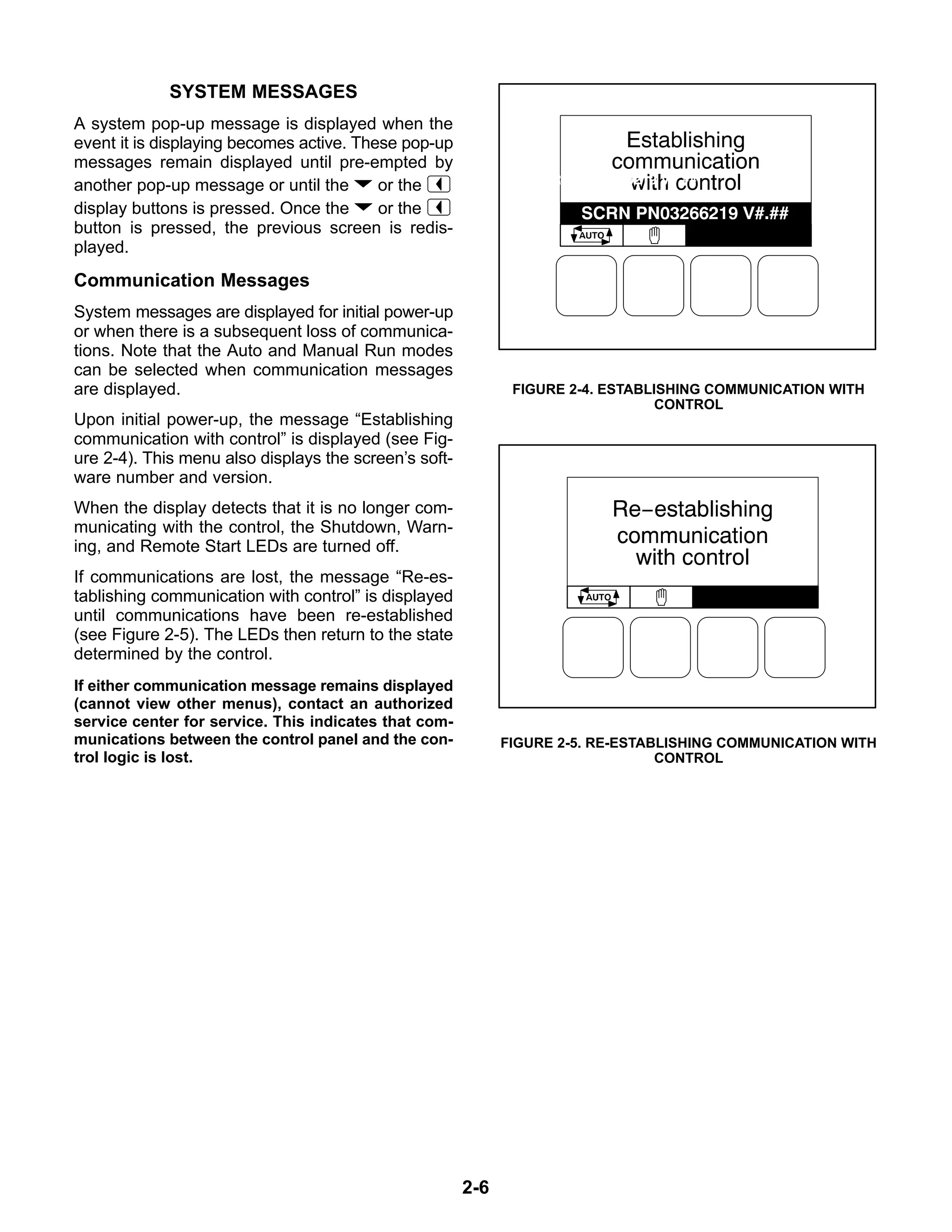

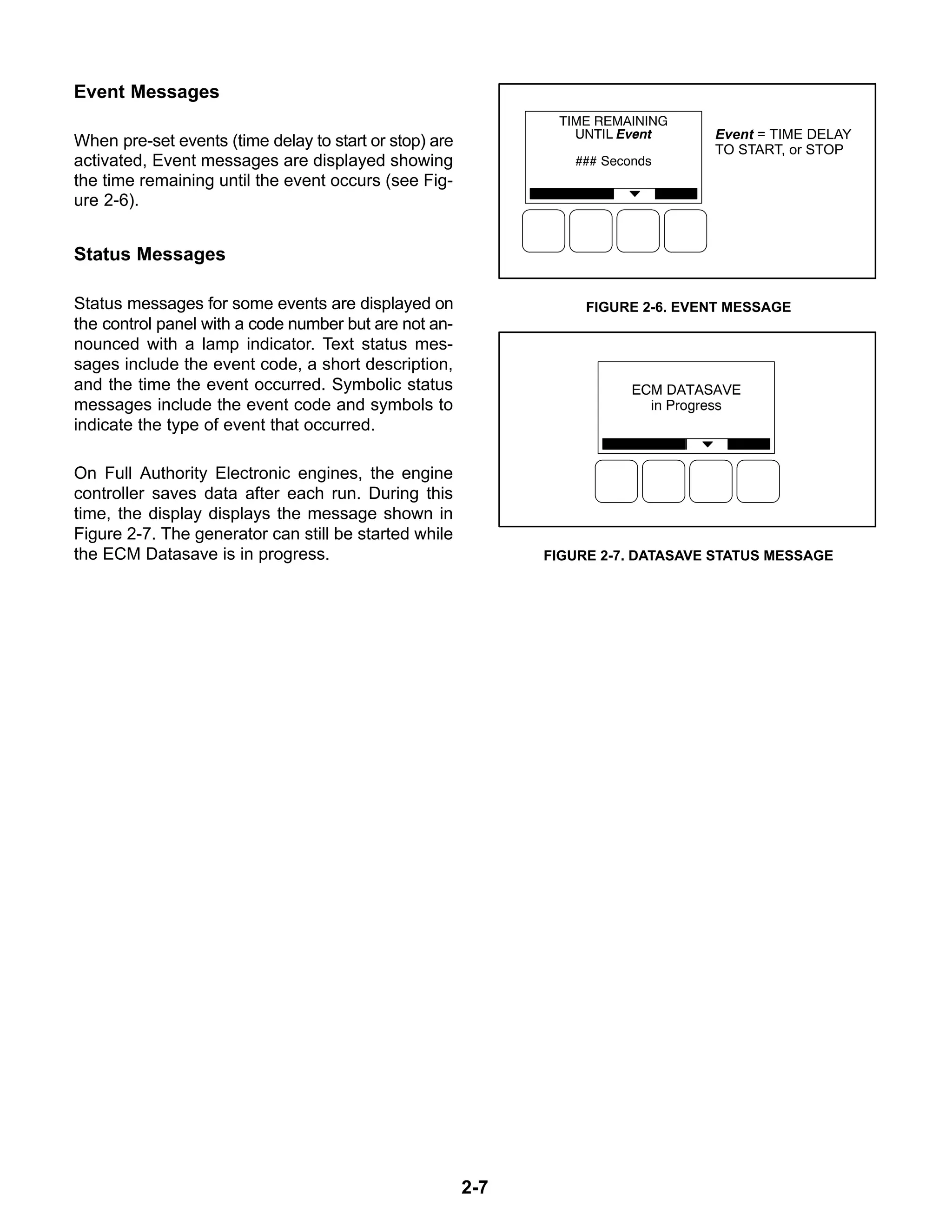

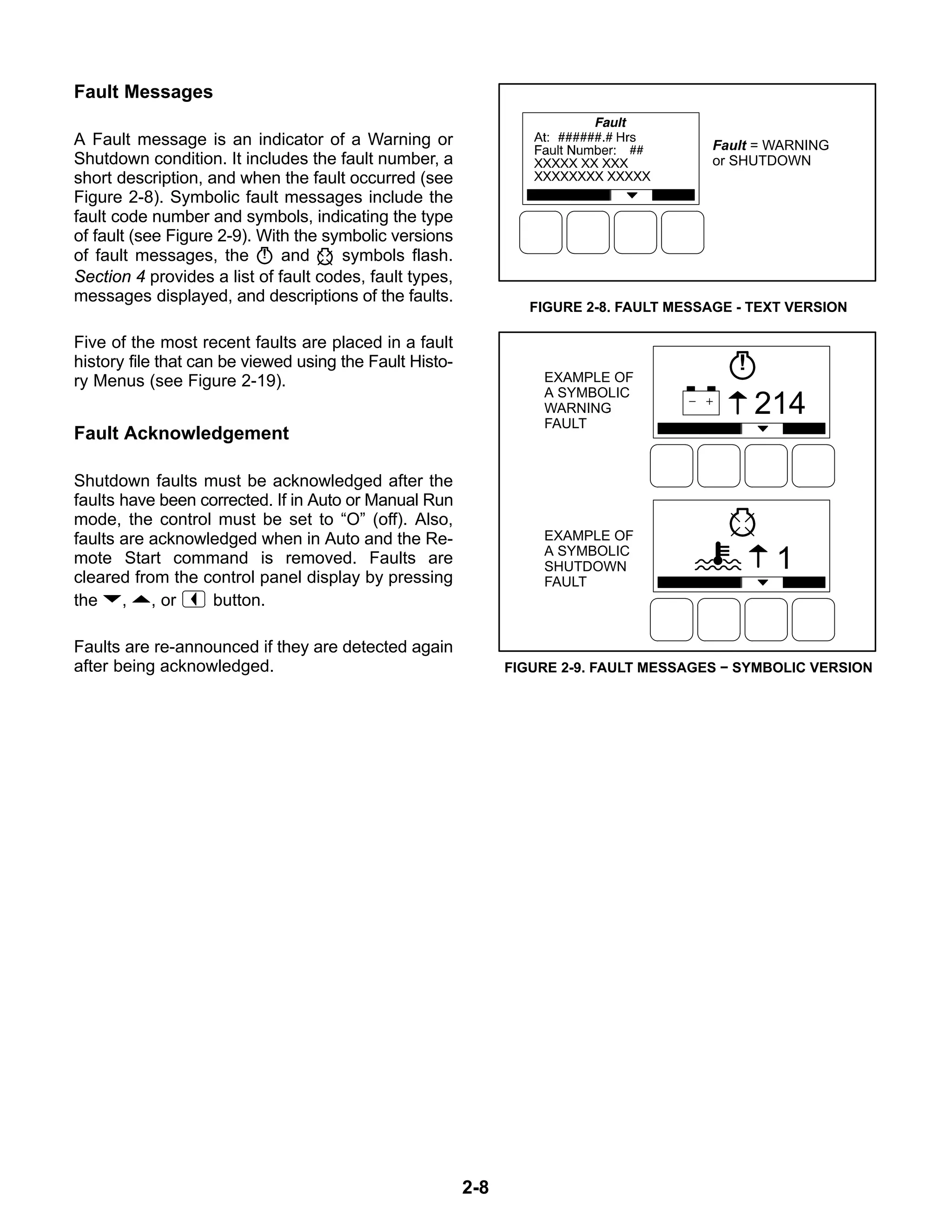

This document is a service manual for various models of generator sets equipped with the PowerCommand® 1302 controller. It includes crucial safety instructions, operational guidelines, and detailed troubleshooting procedures. The manual intends to ensure safe and efficient operation and maintenance of the generator equipment.