CRPS_The_IPV_System

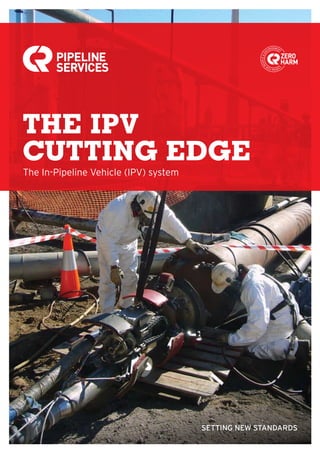

- 1. OUR MISSION // OUR VALUES // “ Setting new standards in specialised industrial services.” Teamwork Performance through teamwork. Innovation Leading in innovative technology and performance. Delivery Changing the critical path by exceeding expectations. Zero Harm Care for health, safety, community and environment. People Our most valuable asset. Customers Working together for continuous improvement. SETTING NEW STANDARDS OPERATION & CREW The IPV system can be adapted to suit most pipeline operations. In deep manholes with no human access, a ‘Launcher’ tube is used. The Launcher is secured and aligned with the pipe to be cleaned, providing the starting point for the cutter, flush with the manhole wall. Control of the IPV is completely remote, keeping the operator safely away from work in progress. With the exception of vacuum storage, all controls and equipment are contained in a small trailer unit, and most operations can be completed with only two people; resulting in a minimal on-site footprint. THE IPV CUTTING EDGE OPERATION 01. IPV Launcher with on board Recovery Winch 02. IPV hydraulic power control unit 03. Cutter breaking through Bauxite deposits in Alumina refinery 04. Cleaning Flare line under inert atmosphere 05. Vacuum truck 01. 03. 04. 05. 02. www.contractresources.com www.contractresources.com NEW ZEALAND Call: +64 9 2652 083 Fax: +64 9 2652 084 Email: crnz@contractresources.com Business Address: 7 Neil Park Drive, East Tamaki Auckland Postal Address: PO Box 204194, Highbrook Manukau City 2161 FOR FURTHER INFORMATION CONTACT // The In-Pipeline Vehicle (IPV) system Quality 100% right first time. Presentation Proud to stand out in a crowd. Success Commercially successful and sustainable.

- 2. The In-Pipeline Vehicle (IPV) system is a truly ground breaking advancement in pipeline cleaning, and is the only waterless technology of its kind; a remotely operated, hydraulically powered in-pipeline robotic vehicle capable of precision cleaning in one pass. The IPV system has a wide range of applications; ranging from removing hazardous substances to cutting and removing extremely hard materials, in a variety of industries. “The IPV system can handle operations that were once impossible; where the only option before was complete pipeline replacement.” 01 Multiple front attachments can be used with the IPV 02 CCTV allows for both real time visual monitoring of work in progress and recording 03 High grade stainless steel construction 04 Unique single actuator design to multiple wall engaging clamps and wheels ensures the unit always remains concentrically aligned TECHNICAL INFO The IPV system is a result of many years of RD, and its applications are ever expanding. Our team of innovative engineers can design and deliver specialised cutters and accessories for a multitude of applications; including cutters incorporating rock drilling technologies to break down very hard deposits and Bead Cutters for removing weld beads in Polyethylene Pipe systems. All waste material is removed at the cutter face, resulting in true one-pass efficiency. THE IN-PIPELINE VEHICLE (IPV) SYSTEM PIPE CLEANING Used for mining and refining processes, the IPV system is able to clean pipes from 280mm in diameter to 1200mm in diameter. Pipes completely filled with liquids, sludges, and very hard solids can all be returned to a clean state in even the most demanding circumstances. The IPV can also be adapted for specialised applications to remove difficult materials, such as concrete liner, and large volume deposits of silt, sand, gravel, or other materials in the pipe. Unlike pressure water jetting, fall of pipe has no effect on the IPV, so it is capable of cleaning in both directions. Consequently, long sections of pipe can be cleaned, with a launch entry at both ends. POLYETHYLENE PIPE WELD BEAD REMOVAL Polyethylene pipe is becoming increasingly common; particularly with the advancements in trenchless pipe-laying technologies. The IPV system can remove internal ‘weld beads’ created in the welding process. 05 In-built failsafe: IPV requires both hydraulic pressure and data to continue operating; if either is lost, wall engaging clamps automatically release and machine can be easily recovered with attached recovery line 06 Robust control system with surge-overload protection and full live status and diagnostics 07 Onboard intelligence relays pipe conditions to the LCD controller display APPLICATIONS FEATURES In Polyethylene pipes it is common to have an oval variance imposed in manufacture from the cutting procedure, and pipe joins can easily be unaligned as a result. The IPV system’s Bead Cutter heads can blend the mismatched edges for a smooth transition between pipes. TRENCHLESS DIRECTIONAL DRILLING The IPV is able to remove drill mud and cuttings from within the polyethylene pipe in larger, open-pipe ‘pullback’ operations. This greatly reduces the risk of a blowout as it relieves pressure build up at the reamer. Cuttings and mud are removed and contained in the vacuum truck or vessel, eliminating the risks of spillage or contamination around the entry pit. The IPV has fine water jets that are able to rinse the pipe wall clean with minimal water usage. Using the IPV system significantly reduces the end volume of waste material compared to conventional pipe cleaning methods. Historically the ability to remove Bauxite, Concrete, Silica, and other hard materials has not been effective using conventional methods, and on occasion the only option has been to replace entire pipelines. This is no longer the case using the IPV. The forward travel speed of the IPV is automatically adjusted depending on the load to the cutter, ensuring the most productive performance relative to the changing volumes and hardness of waste material encountered. Waste removal can be tailored to the client; with bulk dumping, bulk bag, bin, and drum options. The data collected from on-board monitoring equipment includes; gradient of pipeline, cutting rate in mm per minute, alignment of IPV, distance travelled, extender ram position, and cutter rotation speed in revolutions per minute - all in real time. High grade stainless steel construction enables operation in hostile environments and atmospheres, including in the presence of hydrocarbons, pyro-phorics and alike with closed loop nitrogen re-circulation. Pipes from 280mm to 1200mm can all be cleaned through the use of the IPV system, often removing deposits which are impossible to clean using conventional methods. The IPV is also able to operate in inert atmospheres and hostile environments, further increasing its range of uses. The IPV’s unique design ensures it remains concentrically aligned in the pipe at all times, cleaning to a tolerance of within 2mm, without risk of damage to pipe walls. Water can be used as lubrication for materials travelling up the vacuum line. The vacuum extraction system means that all waste materials are removed at the cutter face; resulting in a safe, clean work site. The control monitor screen displays machine status and live performance information, and live CCTV footage is displayed on a separate LCD screen with a heads up display showing cleaning rate and distance travelled. This footage can be saved to DVD or other digital storage device. 01. Flare line before cleaning 02. Flare line after cleaning 03. Bead cutting launch 04. Range of IPVs 05. Bauxite in 900mm internal diameter pipe 01. 04. 05. 02. 03. SETTING NEW STANDARDS www.contractresources.com 01 03 04 05 06 07 08 09 02 WASTE REMOVAL A vacuum hose operating in a closed system means the IPV is adaptable for all manner of waste removal. Various liquids, sludges, and solids - including acidic, alkaline, or toxic - can all be safely dislodged and removed with no risk to surrounding areas or people. Removed waste can then be stored or disposed of as needed. HAZARDOUS OR TOXIC SPILLS IN PIPELINES As the IPV system collects material at the source, which is then transported inside a vacuum line, toxic or hazardous substances entering a storm water line can be removed in the localised area. 08 Powerful extender ram enables IPV to draw up to 150 metres of vacuum and umbilical line 09 Vacuum line removes waste as it is dislodged by the cutter, safely transporting it to containment vessels and eliminating the risk of contamination to the surrounding work environment

- 3. OUR MISSION // OUR VALUES // “ Setting new standards in specialised industrial services.” Teamwork Performance through teamwork. Innovation Leading in innovative technology and performance. Delivery Changing the critical path by exceeding expectations. Zero Harm Care for health, safety, community and environment. People Our most valuable asset. Customers Working together for continuous improvement. SETTING NEW STANDARDS OPERATION CREW The IPV system can be adapted to suit most pipeline operations. In deep manholes with no human access, a ‘Launcher’ tube is used. The Launcher is secured and aligned with the pipe to be cleaned, providing the starting point for the cutter, flush with the manhole wall. Control of the IPV is completely remote, keeping the operator safely away from work in progress. With the exception of vacuum storage, all controls and equipment are contained in a small trailer unit, and most operations can be completed with only two people; resulting in a minimal on-site footprint. THE IPV CUTTING EDGE OPERATION 01. IPV Launcher with on board Recovery Winch 02. IPV hydraulic power control unit 03. Cutter breaking through Bauxite deposits in Alumina refinery 04. Cleaning Flare line under inert atmosphere 05. Vacuum truck 01. 03. 04. 05. 02. www.contractresources.com www.contractresources.com NEW ZEALAND Call: +64 9 2652 083 Fax: +64 9 2652 084 Email: crnz@contractresources.com Business Address: 7 Neil Park Drive, East Tamaki Auckland Postal Address: PO Box 204194, Highbrook Manukau City 2161 FOR FURTHER INFORMATION CONTACT // The In-Pipeline Vehicle (IPV) system Quality 100% right first time. Presentation Proud to stand out in a crowd. Success Commercially successful and sustainable.

- 4. The In-Pipeline Vehicle (IPV) system is a truly ground breaking advancement in pipeline cleaning, and is the only waterless technology of its kind; a remotely operated, hydraulically powered in-pipeline robotic vehicle capable of precision cleaning in one pass. The IPV system has a wide range of applications; ranging from removing hazardous substances to cutting and removing extremely hard materials, in a variety of industries. “The IPV system can handle operations that were once impossible; where the only option before was complete pipeline replacement.” 01 Multiple front attachments can be used with the IPV 02 CCTV allows for both real time visual monitoring of work in progress and recording 03 High grade stainless steel construction 04 Unique single actuator design to multiple wall engaging clamps and wheels ensures the unit always remains concentrically aligned TECHNICAL INFO The IPV system is a result of many years of RD, and its applications are ever expanding. Our team of innovative engineers can design and deliver specialised cutters and accessories for a multitude of applications; including cutters incorporating rock drilling technologies to break down very hard deposits and Bead Cutters for removing weld beads in Polyethylene Pipe systems. All waste material is removed at the cutter face, resulting in true one-pass efficiency. THE IN-PIPELINE VEHICLE (IPV) SYSTEM PIPE CLEANING Used for mining and refining processes, the IPV system is able to clean pipes from 280mm in diameter to 1200mm in diameter. Pipes completely filled with liquids, sludges, and very hard solids can all be returned to a clean state in even the most demanding circumstances. The IPV can also be adapted for specialised applications to remove difficult materials, such as concrete liner, and large volume deposits of silt, sand, gravel, or other materials in the pipe. Unlike pressure water jetting, fall of pipe has no effect on the IPV, so it is capable of cleaning in both directions. Consequently, long sections of pipe can be cleaned, with a launch entry at both ends. POLYETHYLENE PIPE WELD BEAD REMOVAL Polyethylene pipe is becoming increasingly common; particularly with the advancements in trenchless pipe-laying technologies. The IPV system can remove internal ‘weld beads’ created in the welding process. 05 In-built failsafe: IPV requires both hydraulic pressure and data to continue operating; if either is lost, wall engaging clamps automatically release and machine can be easily recovered with attached recovery line 06 Robust control system with surge-overload protection and full live status and diagnostics 07 Onboard intelligence relays pipe conditions to the LCD controller display APPLICATIONS FEATURES In Polyethylene pipes it is common to have an oval variance imposed in manufacture from the cutting procedure, and pipe joins can easily be unaligned as a result. The IPV system’s Bead Cutter heads can blend the mismatched edges for a smooth transition between pipes. TRENCHLESS DIRECTIONAL DRILLING The IPV is able to remove drill mud and cuttings from within the polyethylene pipe in larger, open-pipe ‘pullback’ operations. This greatly reduces the risk of a blowout as it relieves pressure build up at the reamer. Cuttings and mud are removed and contained in the vacuum truck or vessel, eliminating the risks of spillage or contamination around the entry pit. The IPV has fine water jets that are able to rinse the pipe wall clean with minimal water usage. Using the IPV system significantly reduces the end volume of waste material compared to conventional pipe cleaning methods. Historically the ability to remove Bauxite, Concrete, Silica, and other hard materials has not been effective using conventional methods, and on occasion the only option has been to replace entire pipelines. This is no longer the case using the IPV. The forward travel speed of the IPV is automatically adjusted depending on the load to the cutter, ensuring the most productive performance relative to the changing volumes and hardness of waste material encountered. Waste removal can be tailored to the client; with bulk dumping, bulk bag, bin, and drum options. The data collected from on-board monitoring equipment includes; gradient of pipeline, cutting rate in mm per minute, alignment of IPV, distance travelled, extender ram position, and cutter rotation speed in revolutions per minute - all in real time. High grade stainless steel construction enables operation in hostile environments and atmospheres, including in the presence of hydrocarbons, pyro-phorics and alike with closed loop nitrogen re-circulation. Pipes from 280mm to 1200mm can all be cleaned through the use of the IPV system, often removing deposits which are impossible to clean using conventional methods. The IPV is also able to operate in inert atmospheres and hostile environments, further increasing its range of uses. The IPV’s unique design ensures it remains concentrically aligned in the pipe at all times, cleaning to a tolerance of within 2mm, without risk of damage to pipe walls. Water can be used as lubrication for materials travelling up the vacuum line. The vacuum extraction system means that all waste materials are removed at the cutter face; resulting in a safe, clean work site. The control monitor screen displays machine status and live performance information, and live CCTV footage is displayed on a separate LCD screen with a heads up display showing cleaning rate and distance travelled. This footage can be saved to DVD or other digital storage device. 01. Flare line before cleaning 02. Flare line after cleaning 03. Bead cutting launch 04. Range of IPVs 05. Bauxite in 900mm internal diameter pipe 01. 04. 05. 02. 03. SETTING NEW STANDARDS www.contractresources.com 01 03 04 05 06 07 08 09 02 WASTE REMOVAL A vacuum hose operating in a closed system means the IPV is adaptable for all manner of waste removal. Various liquids, sludges, and solids - including acidic, alkaline, or toxic - can all be safely dislodged and removed with no risk to surrounding areas or people. Removed waste can then be stored or disposed of as needed. HAZARDOUS OR TOXIC SPILLS IN PIPELINES As the IPV system collects material at the source, which is then transported inside a vacuum line, toxic or hazardous substances entering a storm water line can be removed in the localised area. 08 Powerful extender ram enables IPV to draw up to 150 metres of vacuum and umbilical line 09 Vacuum line removes waste as it is dislodged by the cutter, safely transporting it to containment vessels and eliminating the risk of contamination to the surrounding work environment

- 5. The In-Pipeline Vehicle (IPV) system is a truly ground breaking advancement in pipeline cleaning, and is the only waterless technology of its kind; a remotely operated, hydraulically powered in-pipeline robotic vehicle capable of precision cleaning in one pass. The IPV system has a wide range of applications; ranging from removing hazardous substances to cutting and removing extremely hard materials, in a variety of industries. “The IPV system can handle operations that were once impossible; where the only option before was complete pipeline replacement.” 01 Multiple front attachments can be used with the IPV 02 CCTV allows for both real time visual monitoring of work in progress and recording 03 High grade stainless steel construction 04 Unique single actuator design to multiple wall engaging clamps and wheels ensures the unit always remains concentrically aligned TECHNICAL INFO The IPV system is a result of many years of RD, and its applications are ever expanding. Our team of innovative engineers can design and deliver specialised cutters and accessories for a multitude of applications; including cutters incorporating rock drilling technologies to break down very hard deposits and Bead Cutters for removing weld beads in Polyethylene Pipe systems. All waste material is removed at the cutter face, resulting in true one-pass efficiency. THE IN-PIPELINE VEHICLE (IPV) SYSTEM PIPE CLEANING Used for mining and refining processes, the IPV system is able to clean pipes from 280mm in diameter to 1200mm in diameter. Pipes completely filled with liquids, sludges, and very hard solids can all be returned to a clean state in even the most demanding circumstances. The IPV can also be adapted for specialised applications to remove difficult materials, such as concrete liner, and large volume deposits of silt, sand, gravel, or other materials in the pipe. Unlike pressure water jetting, fall of pipe has no effect on the IPV, so it is capable of cleaning in both directions. Consequently, long sections of pipe can be cleaned, with a launch entry at both ends. POLYETHYLENE PIPE WELD BEAD REMOVAL Polyethylene pipe is becoming increasingly common; particularly with the advancements in trenchless pipe-laying technologies. The IPV system can remove internal ‘weld beads’ created in the welding process. 05 In-built failsafe: IPV requires both hydraulic pressure and data to continue operating; if either is lost, wall engaging clamps automatically release and machine can be easily recovered with attached recovery line 06 Robust control system with surge-overload protection and full live status and diagnostics 07 Onboard intelligence relays pipe conditions to the LCD controller display APPLICATIONS FEATURES In Polyethylene pipes it is common to have an oval variance imposed in manufacture from the cutting procedure, and pipe joins can easily be unaligned as a result. The IPV system’s Bead Cutter heads can blend the mismatched edges for a smooth transition between pipes. TRENCHLESS DIRECTIONAL DRILLING The IPV is able to remove drill mud and cuttings from within the polyethylene pipe in larger, open-pipe ‘pullback’ operations. This greatly reduces the risk of a blowout as it relieves pressure build up at the reamer. Cuttings and mud are removed and contained in the vacuum truck or vessel, eliminating the risks of spillage or contamination around the entry pit. The IPV has fine water jets that are able to rinse the pipe wall clean with minimal water usage. Using the IPV system significantly reduces the end volume of waste material compared to conventional pipe cleaning methods. Historically the ability to remove Bauxite, Concrete, Silica, and other hard materials has not been effective using conventional methods, and on occasion the only option has been to replace entire pipelines. This is no longer the case using the IPV. The forward travel speed of the IPV is automatically adjusted depending on the load to the cutter, ensuring the most productive performance relative to the changing volumes and hardness of waste material encountered. Waste removal can be tailored to the client; with bulk dumping, bulk bag, bin, and drum options. The data collected from on-board monitoring equipment includes; gradient of pipeline, cutting rate in mm per minute, alignment of IPV, distance travelled, extender ram position, and cutter rotation speed in revolutions per minute - all in real time. High grade stainless steel construction enables operation in hostile environments and atmospheres, including in the presence of hydrocarbons, pyro-phorics and alike with closed loop nitrogen re-circulation. Pipes from 280mm to 1200mm can all be cleaned through the use of the IPV system, often removing deposits which are impossible to clean using conventional methods. The IPV is also able to operate in inert atmospheres and hostile environments, further increasing its range of uses. The IPV’s unique design ensures it remains concentrically aligned in the pipe at all times, cleaning to a tolerance of within 2mm, without risk of damage to pipe walls. Water can be used as lubrication for materials travelling up the vacuum line. The vacuum extraction system means that all waste materials are removed at the cutter face; resulting in a safe, clean work site. The control monitor screen displays machine status and live performance information, and live CCTV footage is displayed on a separate LCD screen with a heads up display showing cleaning rate and distance travelled. This footage can be saved to DVD or other digital storage device. 01. Flare line before cleaning 02. Flare line after cleaning 03. Bead cutting launch 04. Range of IPVs 05. Bauxite in 900mm internal diameter pipe 01. 04. 05. 02. 03. SETTING NEW STANDARDS www.contractresources.com 01 03 04 05 06 07 08 09 02 WASTE REMOVAL A vacuum hose operating in a closed system means the IPV is adaptable for all manner of waste removal. Various liquids, sludges, and solids - including acidic, alkaline, or toxic - can all be safely dislodged and removed with no risk to surrounding areas or people. Removed waste can then be stored or disposed of as needed. HAZARDOUS OR TOXIC SPILLS IN PIPELINES As the IPV system collects material at the source, which is then transported inside a vacuum line, toxic or hazardous substances entering a storm water line can be removed in the localised area. 08 Powerful extender ram enables IPV to draw up to 150 metres of vacuum and umbilical line 09 Vacuum line removes waste as it is dislodged by the cutter, safely transporting it to containment vessels and eliminating the risk of contamination to the surrounding work environment

- 6. FOR FURTHER INFORMATION CONTACT // AUSTRALIA sales@contractresources.com Phone 1300 66 11 91 SYDNEY OFFICE 269 Edgar Street Condell Park, NSW 2200 Phone: +61 (0)2 8723 2111 Fax: +61 (0)2 8723 2199 ADELAIDE OFFICE 6 Sherriffs Road Lonsdale, SA 5160 PO Box 222, Morphett Vale, SA 5162 Phone: +61 (0)8 8186 9900 Fax: +61 (0)8 8186 9999 MELBOURNE OFFICE 9 Bentley St, Williamstown North, VIC 3016 Phone: +61 (0)3 9399 9777 Fax: +61 (0)3 9399 9787 BRISBANE OFFICE 88 Lavarack Ave Eagle Farm, QLD 4009 Phone: +61 (0)7 3268 8711 Fax: +61 (0)7 3268 8799 DARWIN OFFICE 22 Muramats Road PO Box 196, Berrimah, NT 0828 Phone: +61 (0)8 8922 4300 Fax: +61 (0)8 8922 4399 PERTH OFFICE 9 Marriott Road, Jandakot, WA 6164 Phone: +61 (0)8 6595 9000 Fax: +61 (0)8 6595 9090 KARRATHA OFFICE 502 Coolawanyah Road Light Industrial Area Karratha, WA 6714 Phone: +61 (0)8 9158 8230 CHINCHILLA OFFICE 183 Burnt Bridge Road Chinchilla, QLD 4413 PO Box 1106 Chinchilla, QLD 4413 Phone: +61 (0)7 4662 7401 Mobile: +61 (0)458 046 419 GLADSTONE OFFICE 86 Callemondah Drive Gladstone, Clinton QLD 4680 Phone: +61 (0)7 4971 5700 Fax: +61 (0)7 4971 5799 NEW ZEALAND crnz@contractresources.com AUCKLAND OFFICE 7 Neil Park Drive, East Tamaki PO Box 204194, Highbrook Manukau City 2161 Phone: +64 (0)9 265 2083 Fax: +64 (0)9 265 2084 SETTING NEW STANDARDS OPERATION CREW The IPV system can be adapted to suit most pipeline operations. In deep manholes with no human access, a ‘Launcher’ tube is used. The Launcher is secured and aligned with the pipe to be cleaned, providing the starting point for the cutter, flush with the manhole wall. Control of the IPV is completely remote, keeping the operator safely away from work in progress. With the exception of vacuum storage, all controls and equipment are contained in a small trailer unit, and most operations can be completed with only two people; resulting in a minimal on-site footprint. THE IPV CUTTING EDGE OPERATION 01. IPV Launcher with on board Recovery Winch 02. IPV hydraulic power control unit 03. Cutter breaking through Bauxite deposits in Alumina refinery 04. Cleaning Flare line under inert atmosphere 05. Vacuum truck 01. 03. 04. 05. 02. www.contractresources.com The In-Pipeline Vehicle (IPV) system www.contractresources.com Contract Resources has equipment spread throughout Australia, New Zealand, North and South America, and the Middle East; ensuring fast mobilisation. Global Network