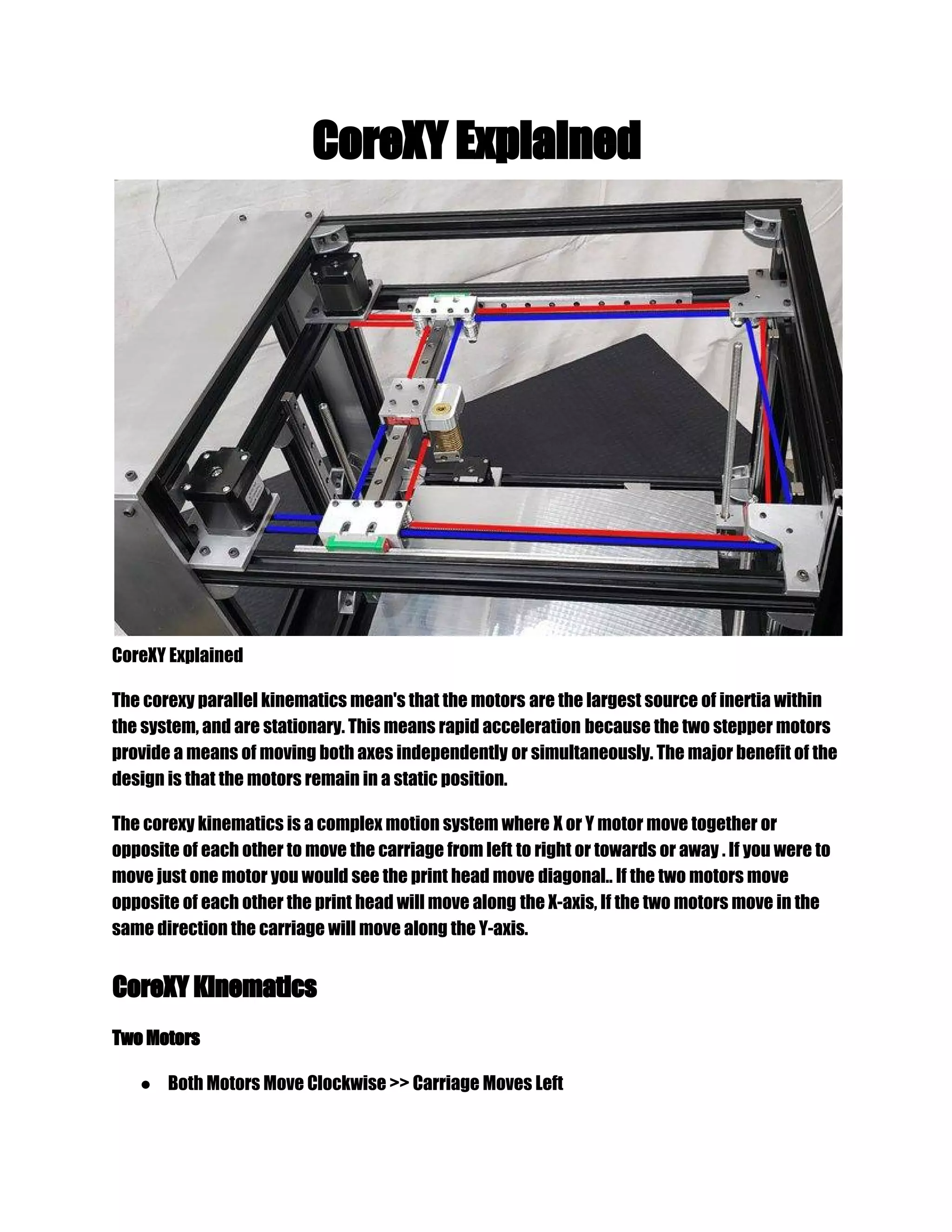

The corexy parallel kinematics design uses two stationary stepper motors that can independently or simultaneously move both the x and y axes. This reduces inertia compared to cartesian designs that use a motor for each axis. The corexy design allows the motors to remain static, providing rapid acceleration, while the complex motion system moves the print head diagonally or along single axes depending on if the motors move together, opposite, or individually. The corexy design is theoretically faster and more accurate than cartesian due to reduced inertia from stationary motors.