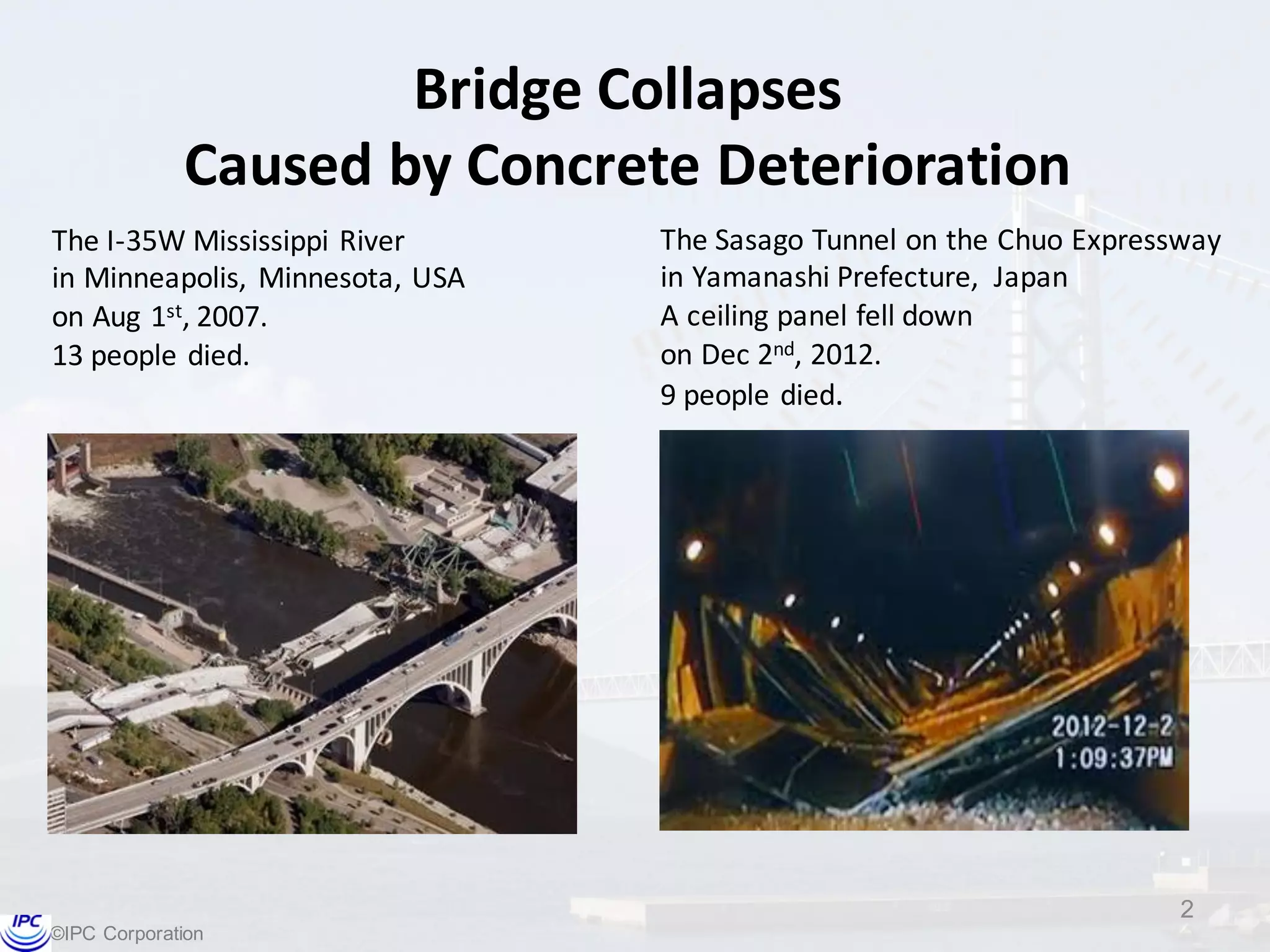

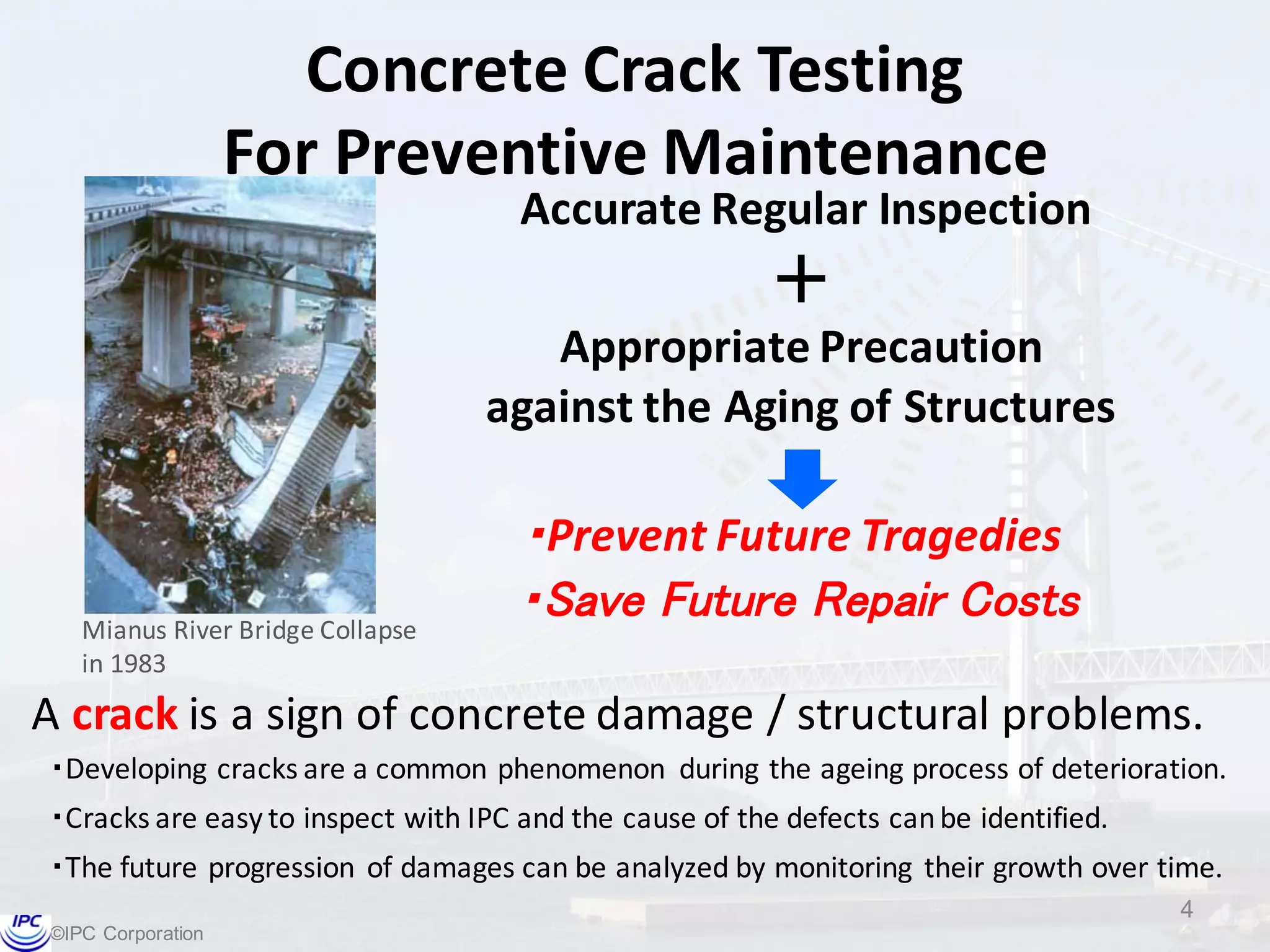

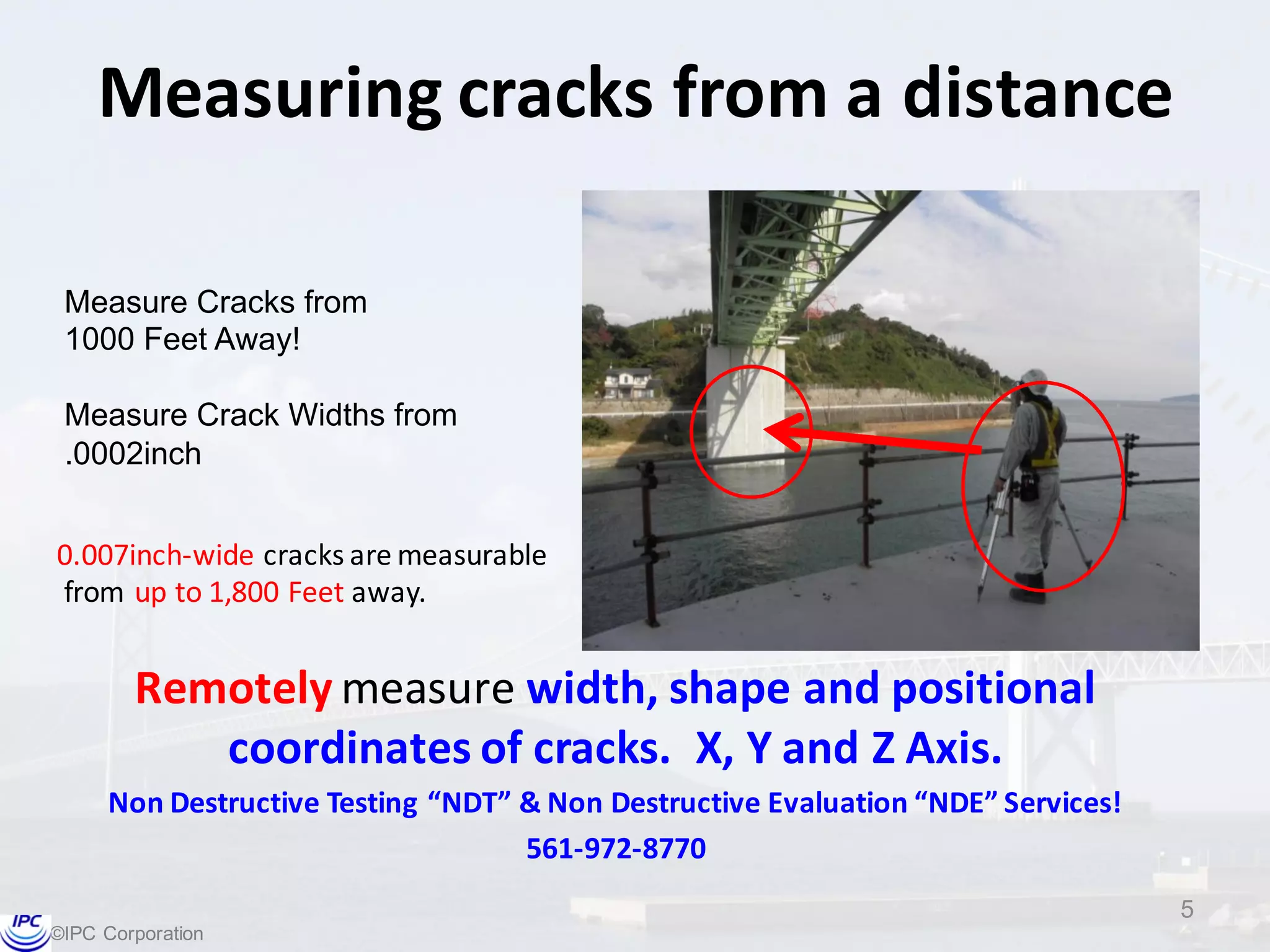

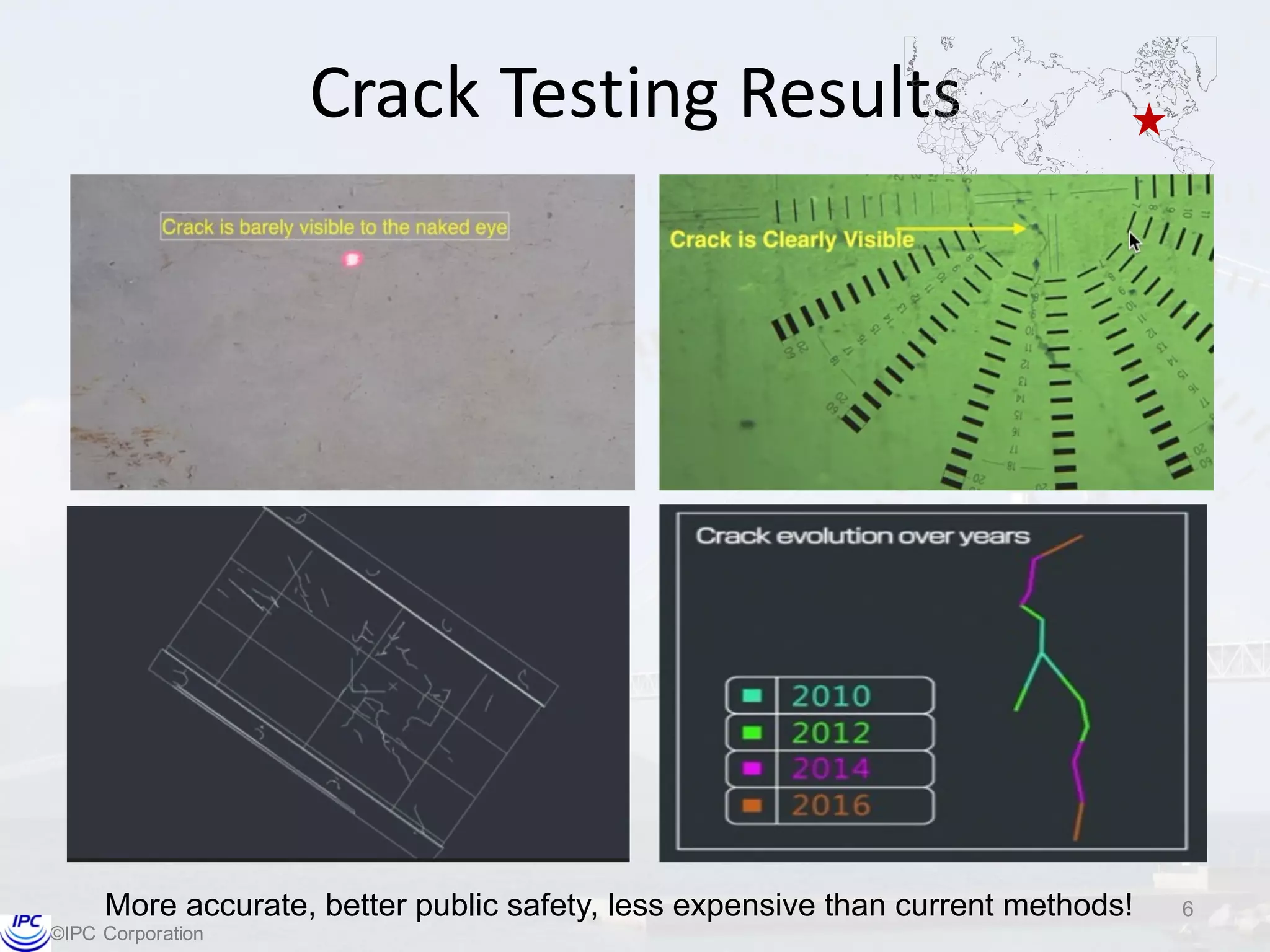

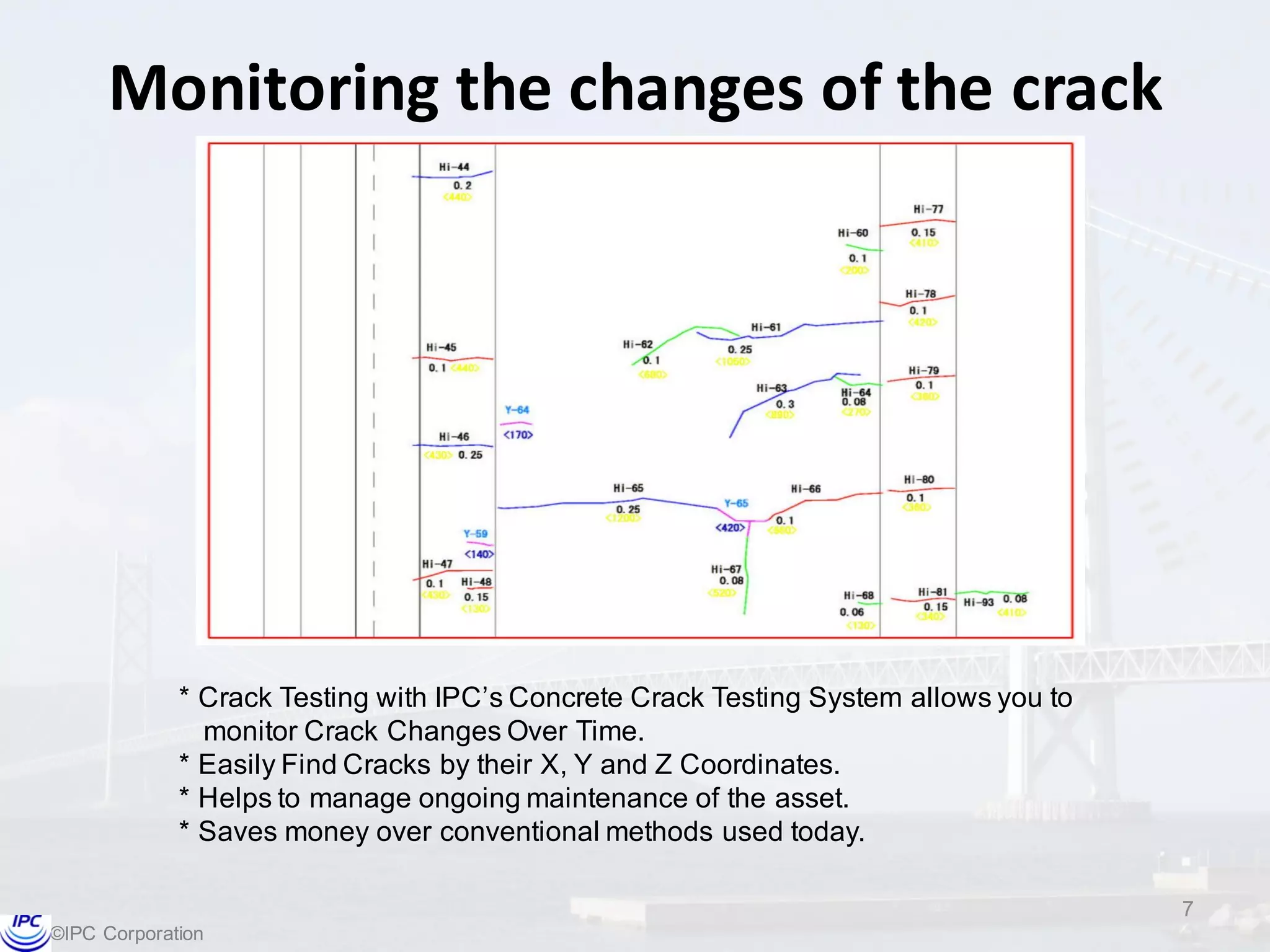

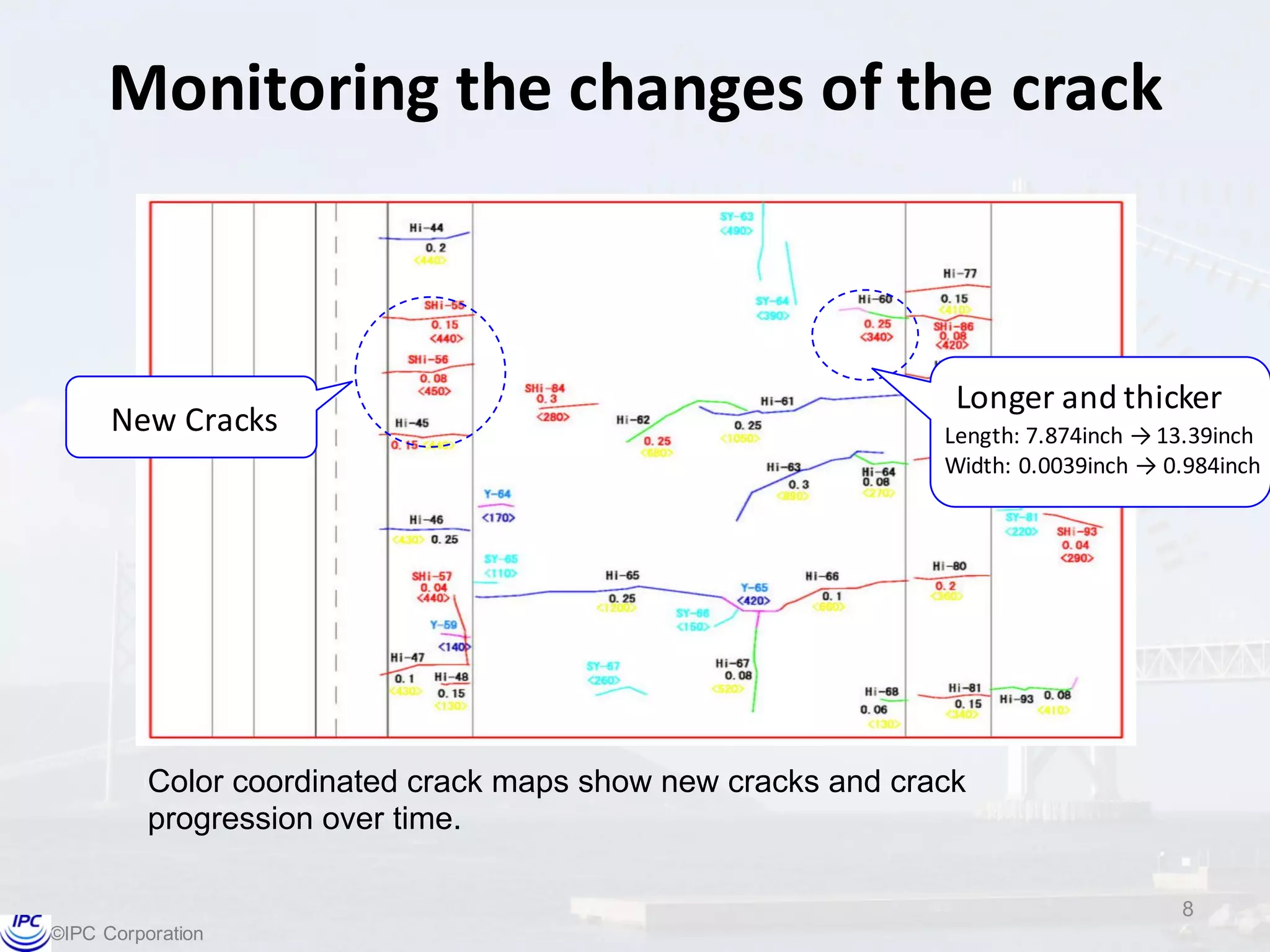

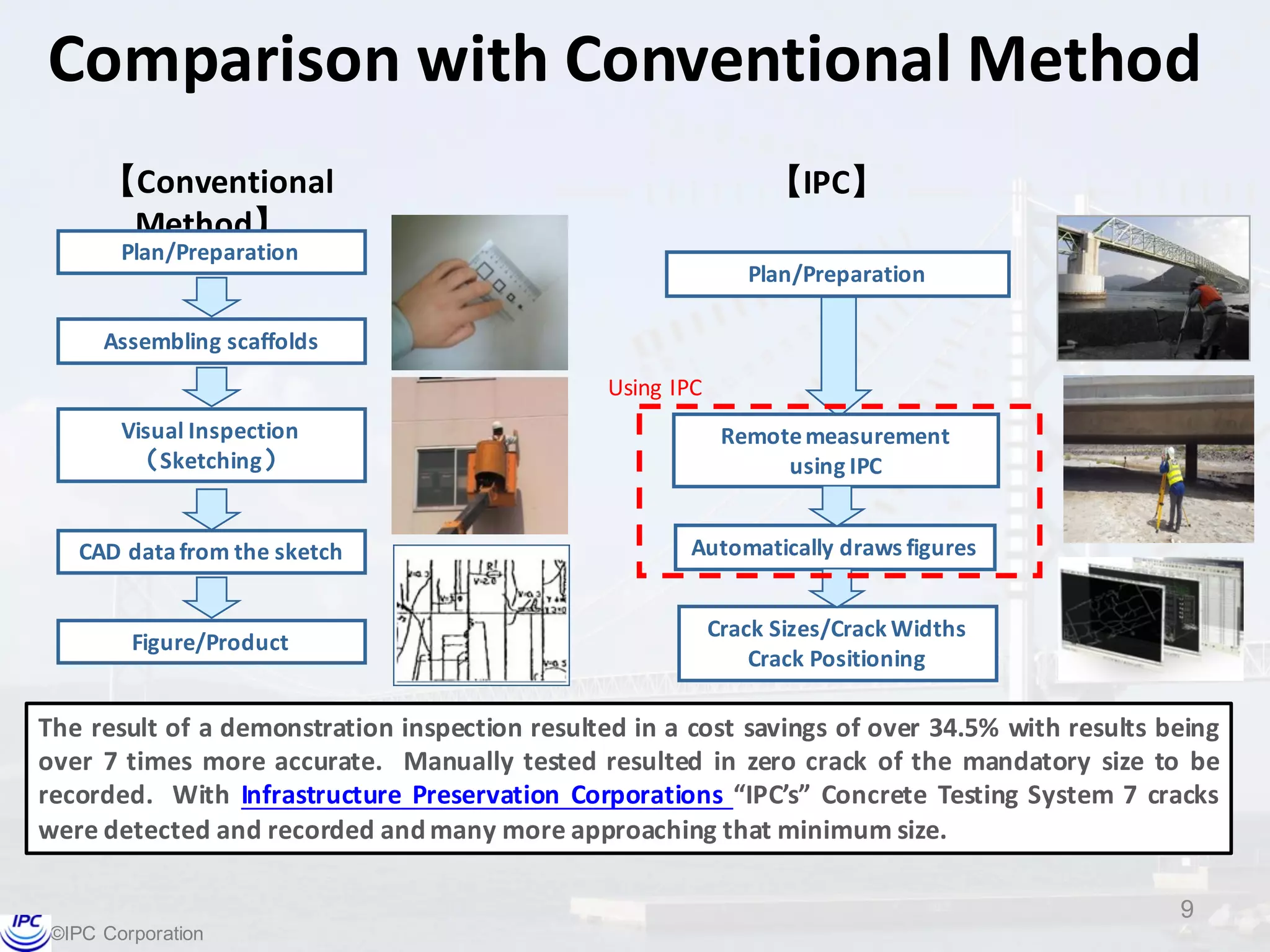

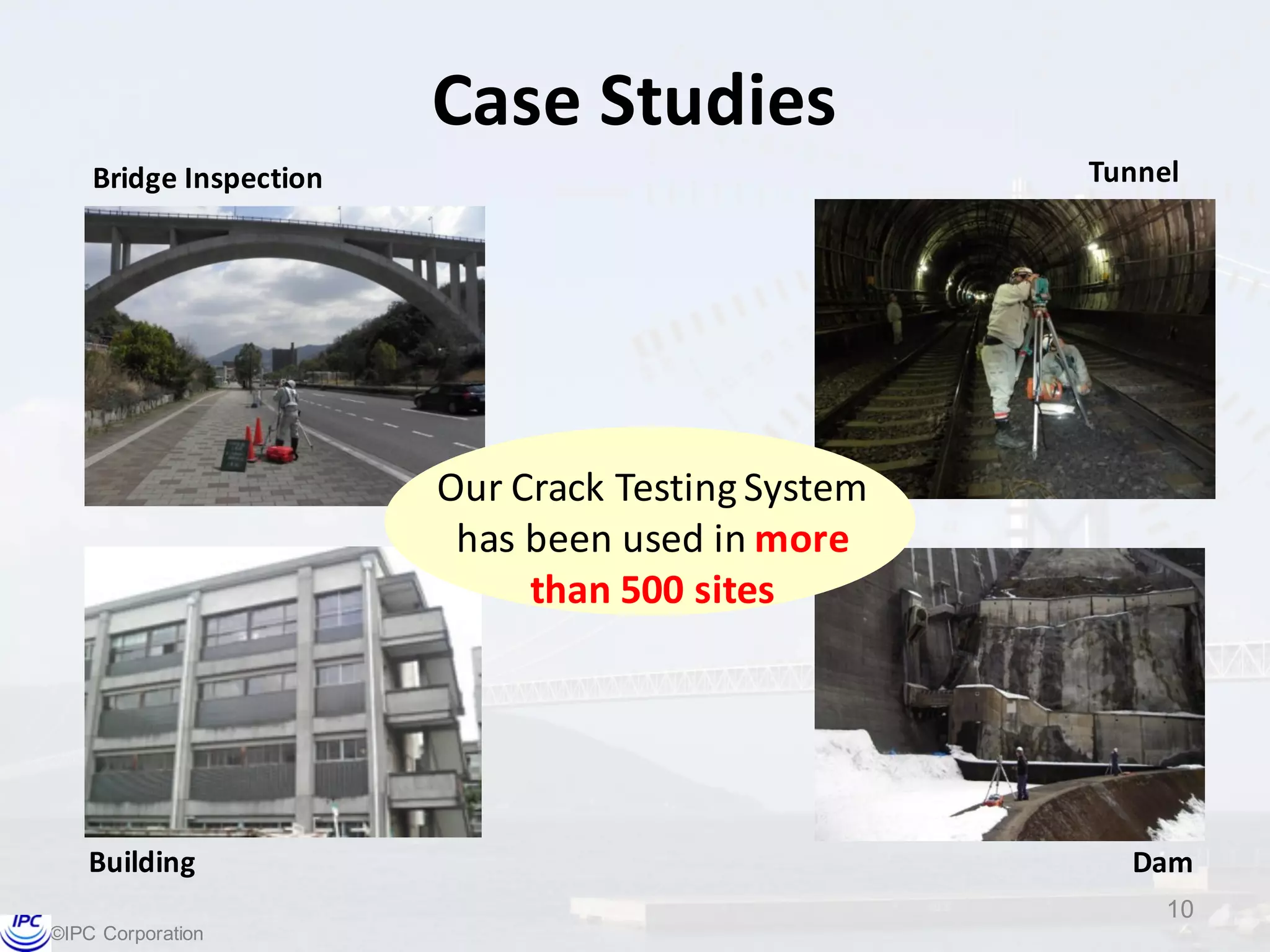

IPC Corporation offers remote concrete crack inspection services to enhance safety and reduce future repair costs associated with structural deterioration. Their non-destructive testing (NDT) technology allows for accurate monitoring of cracks from significant distances, providing detailed data on crack progression and facilitating effective maintenance. With proven cost savings and improved accuracy over conventional methods, IPC's system has been employed in over 500 sites to monitor and assess concrete integrity.