This document discusses various methods for capturing carbon dioxide (CO2) from industrial processes and power plant flue gases. It describes both established and developing absorption-based techniques using liquid solvents such as amines, ionic liquids, and hyperbranched polymers. While amine scrubbing is a mature process, opportunities exist to improve solvent capacity and reduce regeneration energy needs through new solvent formulations and process designs. Developing technologies like facilitated transport membranes and task-specific ionic liquids also aim to enhance CO2 capture efficiency. Fundamental research on reaction mechanisms and new candidate materials continues to inform the design of more effective and economical CO2 capture systems.

![Anion and Cation Effects on the Solubility of CO2

70

O

[bmim][PF6]

60

[bmim][BF4]

F3C

[bmim][Tf2N]

50

[MeBu3N][Tf2N]

40

S

S

O

[MeBuPyrr][Tf2N]

N

O

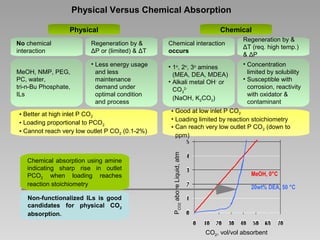

Anion effect

Cation effect

10

0

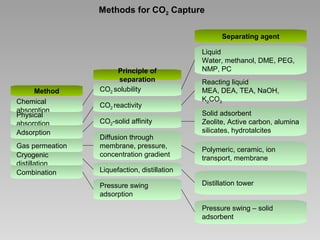

Henry’s law constants (bar) for CO2 in various ILs

CF3

F

F

F

P

F

F

F

determining the

CO2 solubility3;

The anions

30

20

O

Fluorinated anions are excellent but

costly, sometimes not

environmentally friendly.

Some strategies in ILs for CO2 absorption8

Creating more free

volume (introducing

ether and long,

branched alkyl chain

on the cation

8. Journal of Physical Chemistry B 109 (2005) 6366

Incorporating with CO2phylic functional groups

(carbonyl, sulfonyl,

phosphate, amine

groups)

Controlling the viscosity

(using dicyanamide

anions, trialkylsulfonium

cation)](https://image.slidesharecdn.com/co2separation-greenchem-proposal-131025084018-phpapp02/85/CO2-Separation-A-Proposal-10-320.jpg)

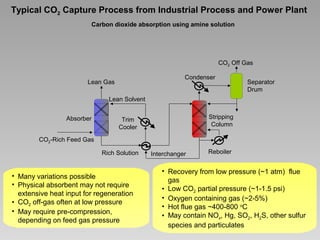

![Poly(ionic liquid)s; Creative Effort13,14,15

*

*

*

n

*

*

*

n

*

*

n

n

x

*

*

1-x

O

x

*

*

1-x

O

O

O

O

O

O

BF4N

N

R

R

R

P[VBTMA][BF4]

BF4

-

N

O

O

n

N

N

R

n

O

P[VBBI][BF4]

P[MABI]BF4

P[VBTMA][BF4]-g-PEG

O

P[MATMA][BF4]-g-PEG

Brittle materials

Current status

O

N

R

Problems

BF4N

R

P[MATMA][BF4]

BF4-

BF4-

N

BF4-

R

R

O

O

Thermodynamics,

kinetics and

mechanism

Low efficiency

Grafting polymers

In progress, limited

results available

Underdeveloped

1.

Opportunities

13. Chem Commun (2005)3325; 14. Ind Eng Chem Res 46(2007)5397; 15. J Membrane Sci 281(2006)130

2.

ILs grafted onto

selective polymers

Specific

membrane](https://image.slidesharecdn.com/co2separation-greenchem-proposal-131025084018-phpapp02/85/CO2-Separation-A-Proposal-13-320.jpg)

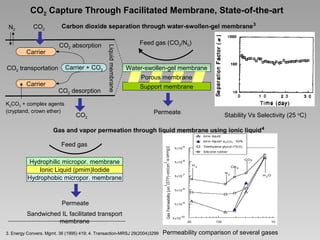

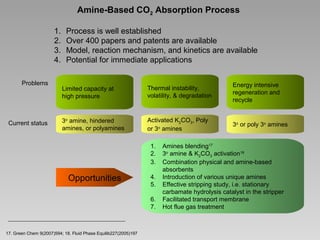

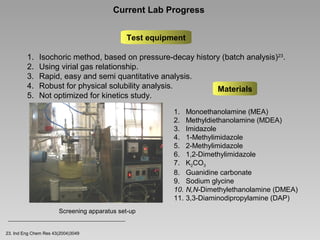

![Total Equilibrium

Pressure (KPa)

Total Equilibrium Pressure (KPa)

Total Pressure equilibrium Vs CO2 capacity (30 mins capacity (30 mins run)

Total Pressure equilibrium Vs CO2 run)

80. 0

80.00

80. 0

Total Equilibrium

Pressure (KPa)

Total equilibrium pressure (KPa)

100.00

60. 0

60.00

60. 0

40. 0

40.00

0.00 5.00

5.00

0.00

10.00

10.00

5.00

10.00

0. 0

15.00

15.00

15.00

mole of CO2/2kg of absorbent

mole of CO / kg of absorbent

60.0

40. 040.0

20. 0

20.00

80.0

20. 020.0

0. 0

0. 0

20.00

0.0

20.00

20.00

0. 4

0.0 0.0

mole of CO2/ kg of absorbent

1mL MDEA + + 4mL H2O

1mL MDEA 4mL H2O

5mL 4.76%wt 2- methylimidazole/ H2O

5mL 4. 76%wt 2- methylimidazole/ H2O

5mL 4.76%wt imidazole/ H2O

5mL 4. 76%wt imidazole/ H2O

5mL 4.76%wt guanidine carbonate/ H2O

5mL 4. 76%wt guanidine carbonate/ H2O

5mL 4.76%wt DMEA/ H2O

5mL 4. 76%wt DMEA/ H2O

5mL 4.76%wt DAP

5mL 4. 76%wt DAP

2mL MDEA +2mL MDEA + 3mL H2O

3mL H2O

5mL 23.08%wt K2CO3/ H2O

5mL 23. 08%wt K2CO3/ H2O

5mL 23.08%wt K2CO3/ H2O K2CO3/ H2O

5mL 23.08%wt

5mL 4.76%wt Naglycine/ H2O

5mL 4.76%wt Naglycine/ H2O

5mL 4.76%wt Naglycine/ H2O

5mL 4.76%wt 1,2- dimethylimidazole/ H2O

5mL 4.76%wt 1,2- dimethylimidazole/ H2O 5mL 4.76%wt Naglycine/ H2O

5mL 4.76%wt MEA/ H2O MEA/ H2O

5mL 4.76%wt

5mL 4.76%wt MEA/ H2O

5mL 4.76%wt MEA/ H2O

5mL 4.76%wt DMEA/ H2O DMEA/ H2O

5mL 4.76%wt

1mL DMEA + + 4mL H2O

1mL DMEA 4mL H2O

4mL 4.76%wt DAP + 1 mL DMEA 1 mL DMEA

4mL 4.76%wt DAP +

1mL

5mL

5mL

5mL

1mL

5mL

2. 0

2.4 2.4

MDEA +1mL MDEA + 4mL H2O

4mL H2O

4.76%wt 2- methylimidazole/ H2O

5mL 4. 76%wt 2- methylimidazol

4.76%wt 1,2- dimethylimidazole/ H2O

5mL 4. 76%wt 1,2- dimethylimid

9.09%wt guan-09%wt guan- car/ H2O

5mL 9. car/ H2O

DMEA +1mL DMEA + 4mL H2O

4mL H2O

4.76%wt DAP 76%wt DAP

5mL 4.

Capacity (mol of CO2/mol absorbent) of various amines

CO

Loading (mol of CO2/kgSolubility (Validation of Experiments)

absorbent) of various amines

2

16

160

[emim]etOSO3

120

CO2 mole fraction (x1000)

140

PCO2 equilibrium (KPa)

1.6

0.0. 8

4

0.8

1.2.0

6

0.4

0.8 1.2 1.2 1.2 1.6

2.0

a (molmol absorbent)

a (mol CO2(mol2/CO2absorbent)

a / CO mol / mol absorbent)

Jones et al; J Chem Eng Data4(1959)85

Shen et al; J Chem Eng Data 37(1992)96

Song et al; J Chem Eng Data 41(1996)497

This work

100

80

60

40

20

0

[emim]etOSO3 + 7.0% w/w ZnBr2

[emim]etOSO3 + 7.0% w/w sugar

12

[bmim]BF4

8

4

0

0. 4

0.5

0. 6

Capacity (mol CO2/ mol of MEA)

0. 7

Experimental Validation of CO2 solubility test (15.3%wt. MEA)

30

50

70

90

110

Pequilibrium (KPa)

Effect of additive on the CO2 absorption capacity of simple ILs](https://image.slidesharecdn.com/co2separation-greenchem-proposal-131025084018-phpapp02/85/CO2-Separation-A-Proposal-21-320.jpg)