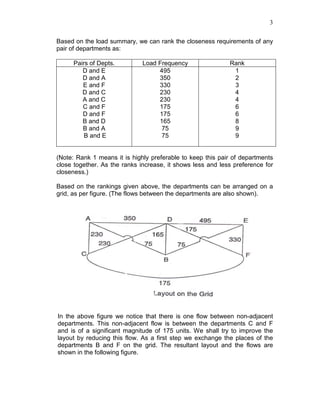

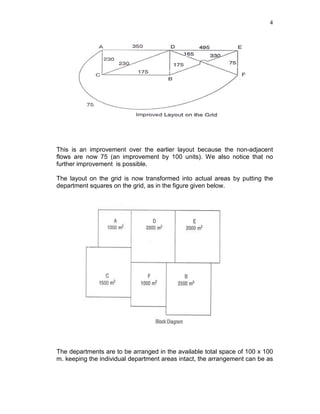

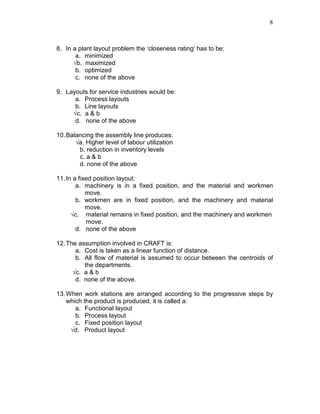

This document discusses plant layout and provides information on various layout types and techniques. It begins by defining a layout and what constitutes a good layout. It then discusses different layout types like process, product, and fixed position layouts. It also covers layout techniques like CRAFT, group technology, and flexible manufacturing systems. The document concludes with objective questions related to plant layout concepts.