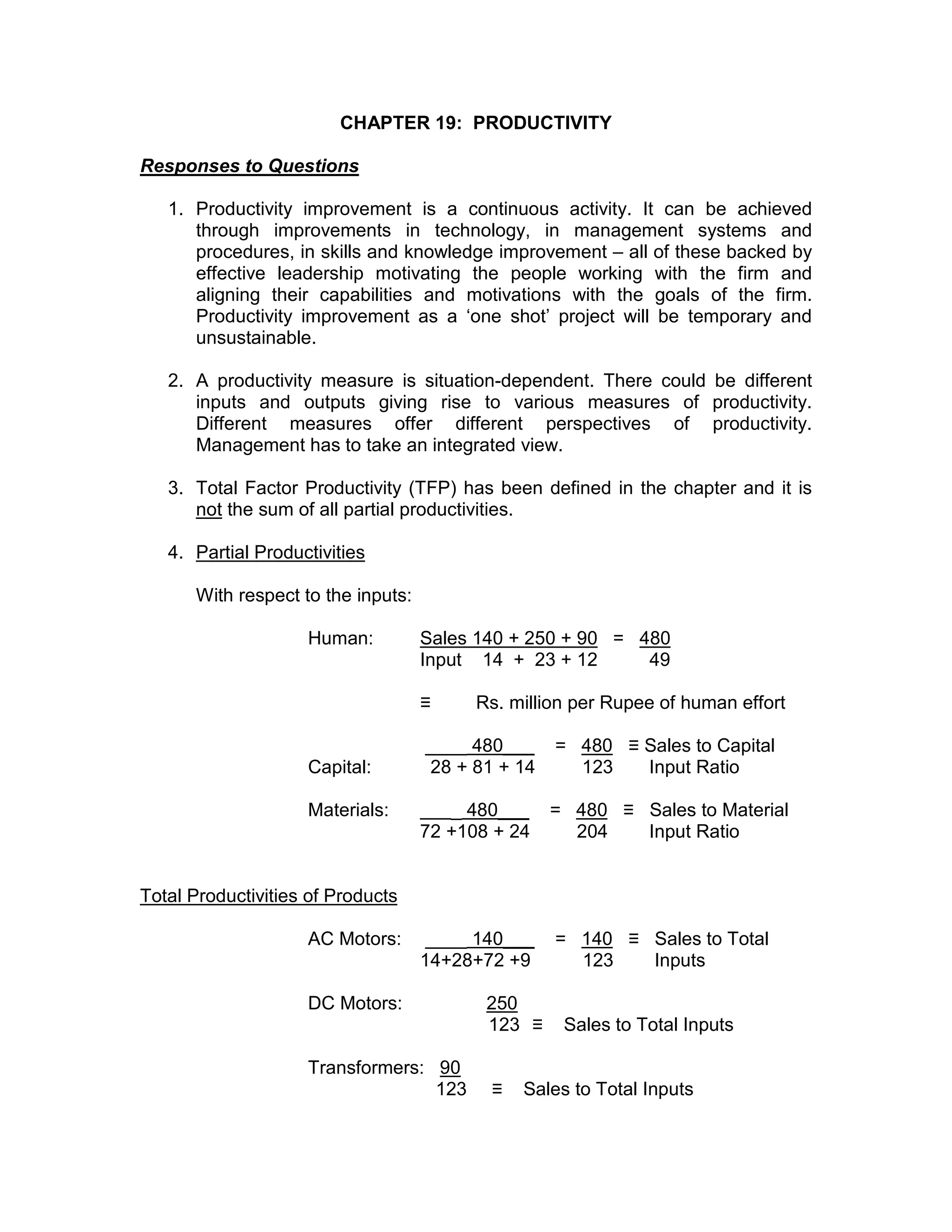

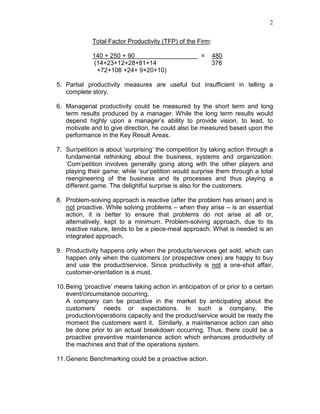

This document discusses productivity and related concepts. It begins by defining productivity improvement as a continuous process achieved through technology, management, skills development, and leadership. Total factor productivity is defined as the ratio of sales to all inputs rather than the sum of partial productivities. Partial productivities measure the relationship between individual inputs and outputs. The document notes various measures of productivity and how they provide different perspectives. It also discusses concepts like benchmarking, total quality management, and business process reengineering in relation to improving productivity.