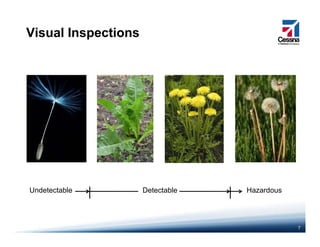

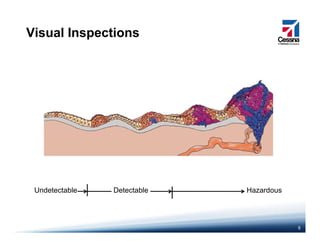

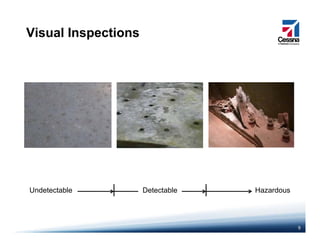

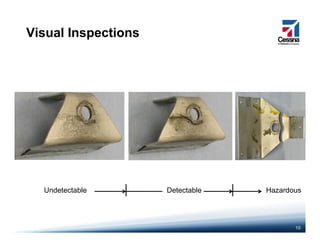

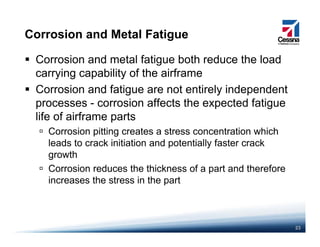

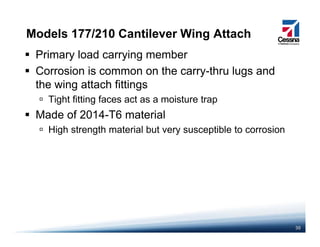

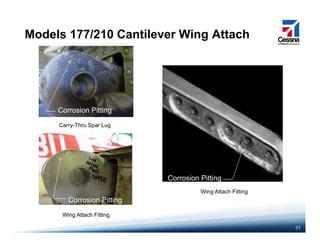

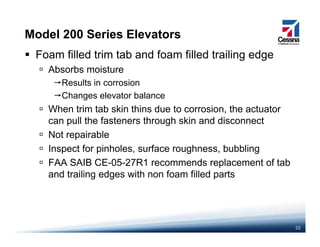

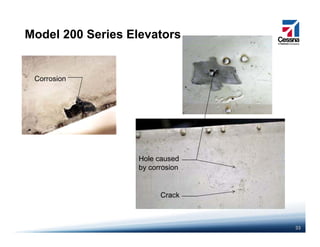

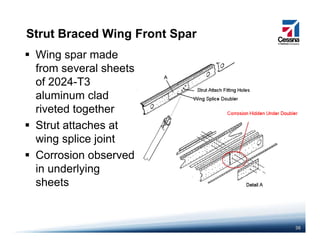

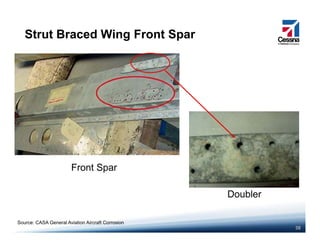

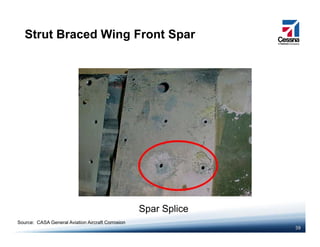

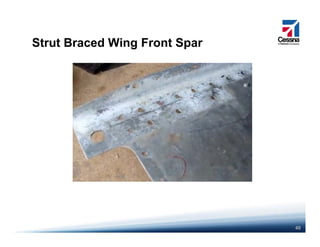

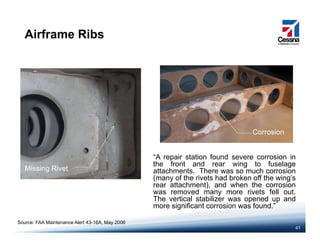

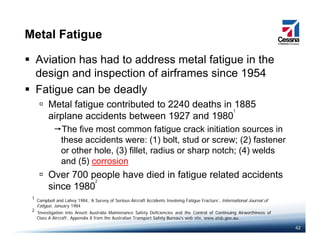

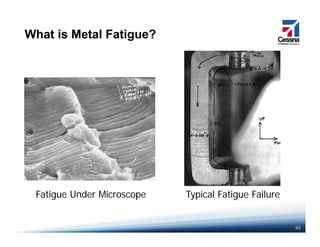

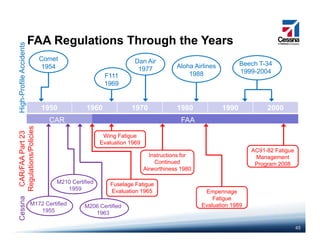

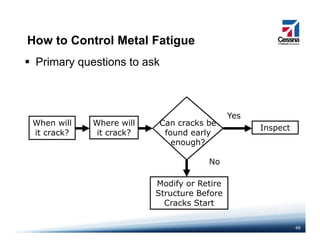

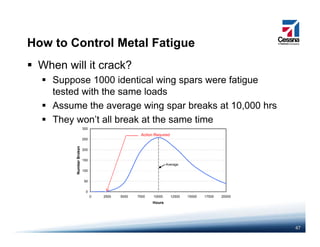

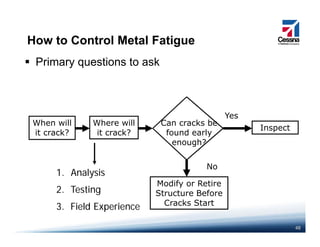

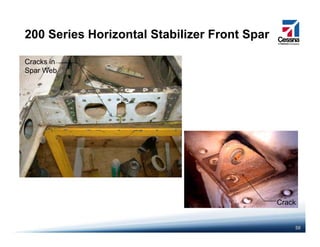

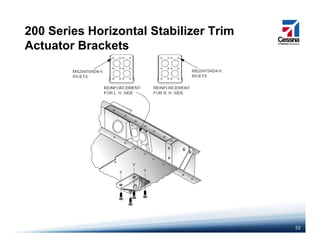

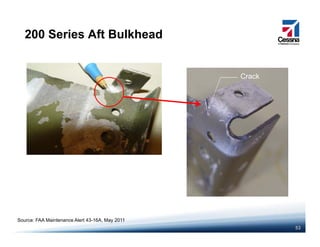

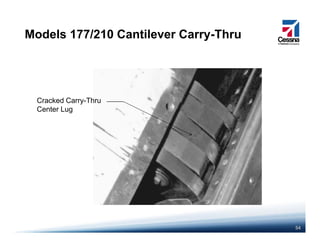

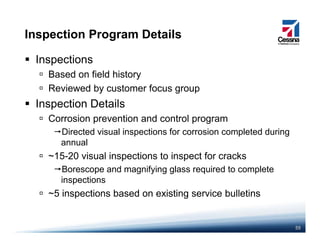

Cessna developed a structural inspection program to ensure the continued safe operation of its single-engine airplanes. Visual inspections are used to detect corrosion and cracks caused by metal fatigue. Corrosion and metal fatigue inevitably reduce the load-carrying capability of aircraft structures over time. Thorough, frequent inspections are needed to maintain aircraft safety as they age. The inspection program aims to find issues before they become hazardous.