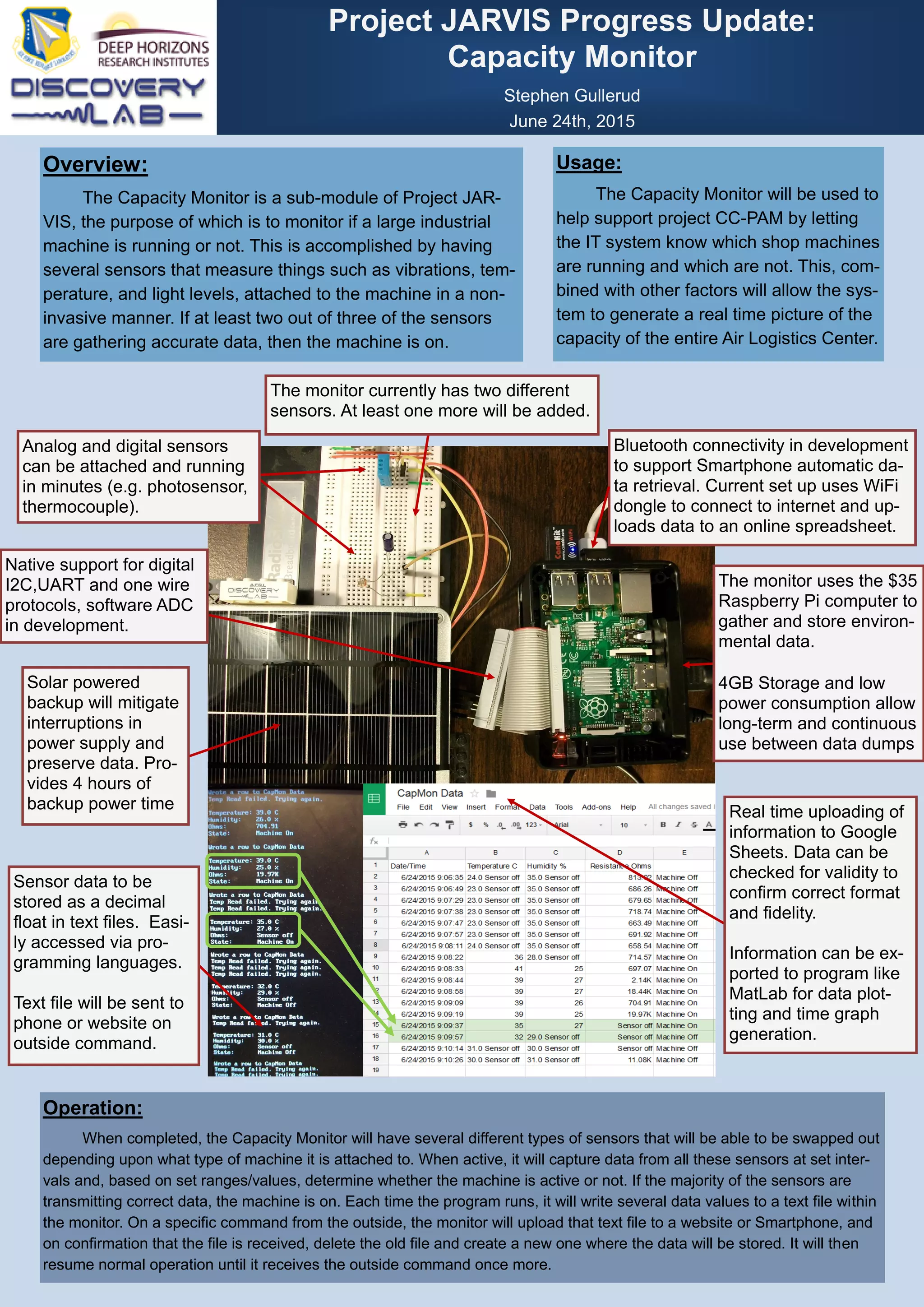

The Capacity Monitor is being developed as part of Project JARVIS to monitor the usage status of machines in a shop in real-time. It uses multiple sensors attached to each machine to determine if it is running or not. When completed, it will be able to swap between different sensor types depending on the machine. The monitor collects data from the sensors periodically and uploads it to a file or website upon receiving an external command, then deletes the old file. This will provide real-time information on machine capacity across the entire facility.