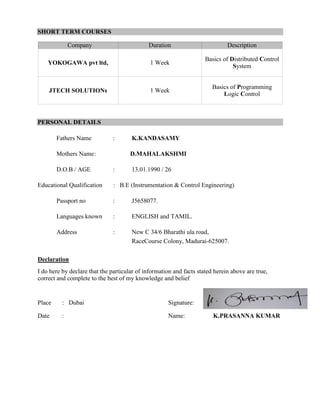

K. Prasanna Kumar provides his resume, including objective, qualifications, professional experience, assignments, skills and education. He has over 4 years of experience calibrating various instruments in fields like pharmaceutical, aerospace and oil and gas. Currently he works as a Quality Calibration Engineer for Phi Sigma Calibration in Dubai, where he helps maintain accreditation and provides training.