The document discusses the butter making process which includes standardization of cream, pasteurization, ripening, churning, washing, salting, working and packaging butter.

Some key points covered are:

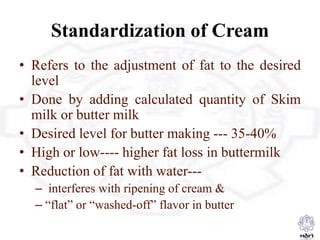

- Cream is standardized to 35-40% fat before pasteurization using skim milk or buttermilk.

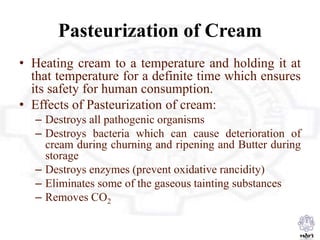

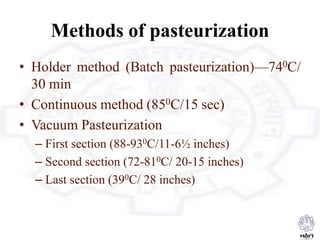

- Pasteurization destroys pathogens and enzymes to ensure safety and stability.

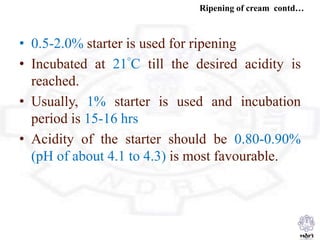

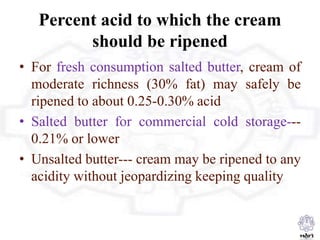

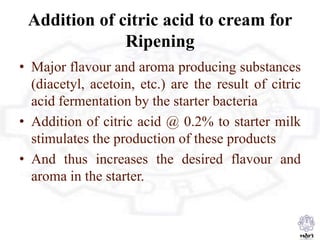

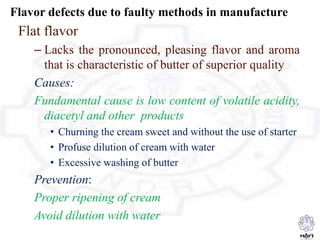

- Ripening with starter culture produces flavors like diacetyl and acids.

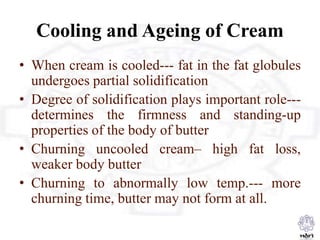

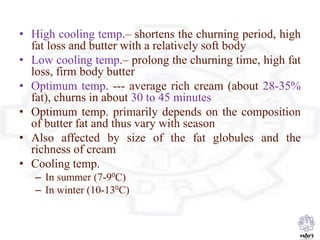

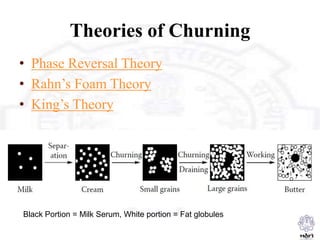

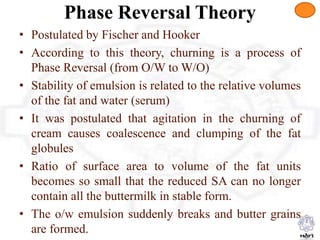

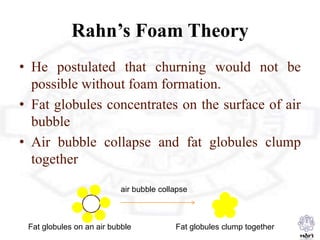

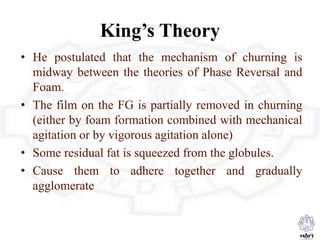

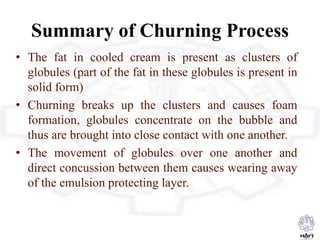

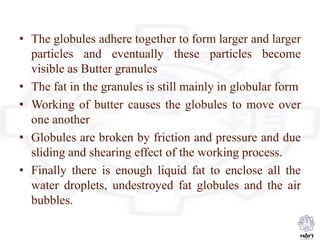

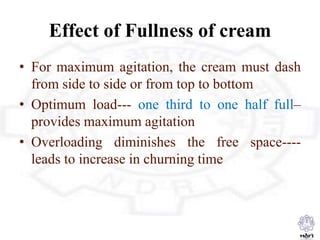

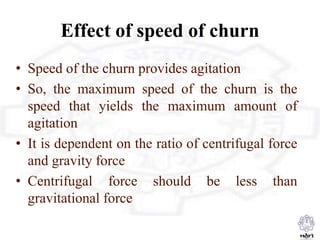

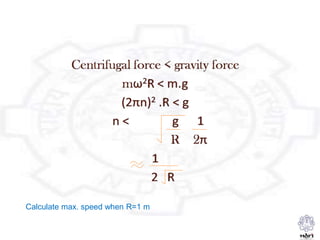

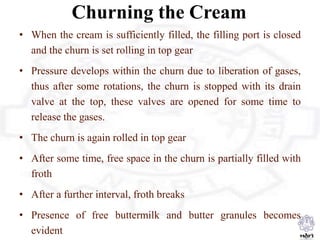

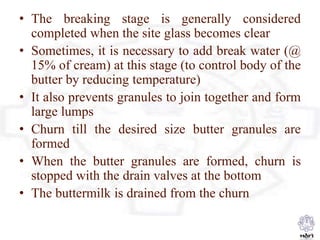

- Churning converts the cream emulsion to butter grains through processes like phase reversal and foam formation.

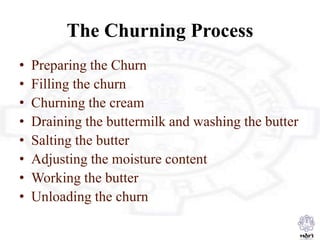

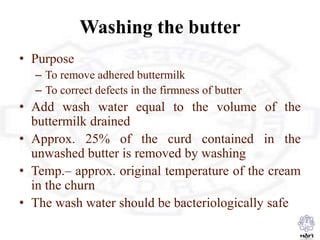

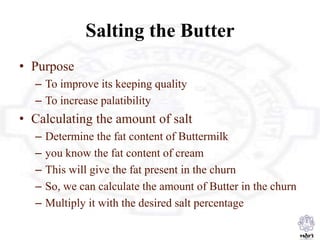

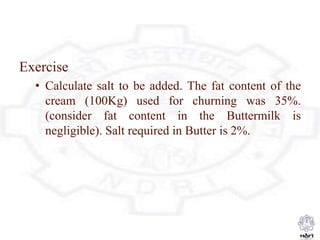

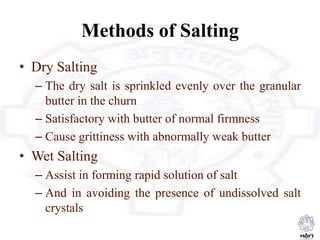

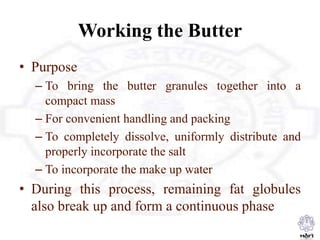

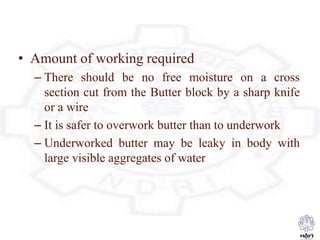

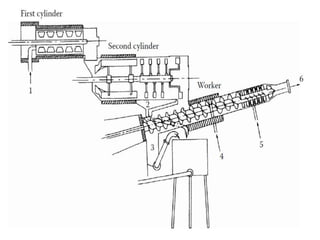

- Washing removes buttermilk, salting improves quality, and working incorporates ingredients uniformly.

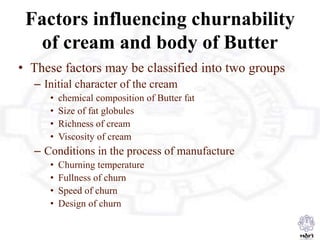

- Factors like temperature