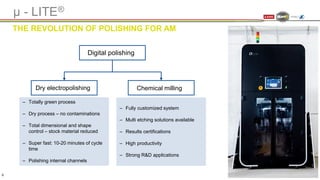

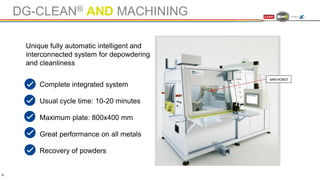

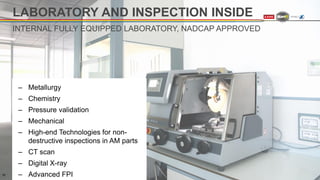

BEAMIT Group is a leading additive manufacturing company that provides end-to-end AM solutions. It has over 50 materials, 5 dedicated plants, over 100 employees, and €17 million in total turnover. In 2019, Sandvik Group acquired a significant stake in BEAMIT. BEAMIT offers a fully integrated value chain including powder production, printing, heat treatment, machining, inspection, and more. It has numerous innovations like its μ-lite digital surface finishing and Hyper advanced heat treatment. BEAMIT aims to further digitally integrate its value chain, expand geographically through M&A, and establish scalable and efficient future series production.