Embed presentation

Downloaded 111 times

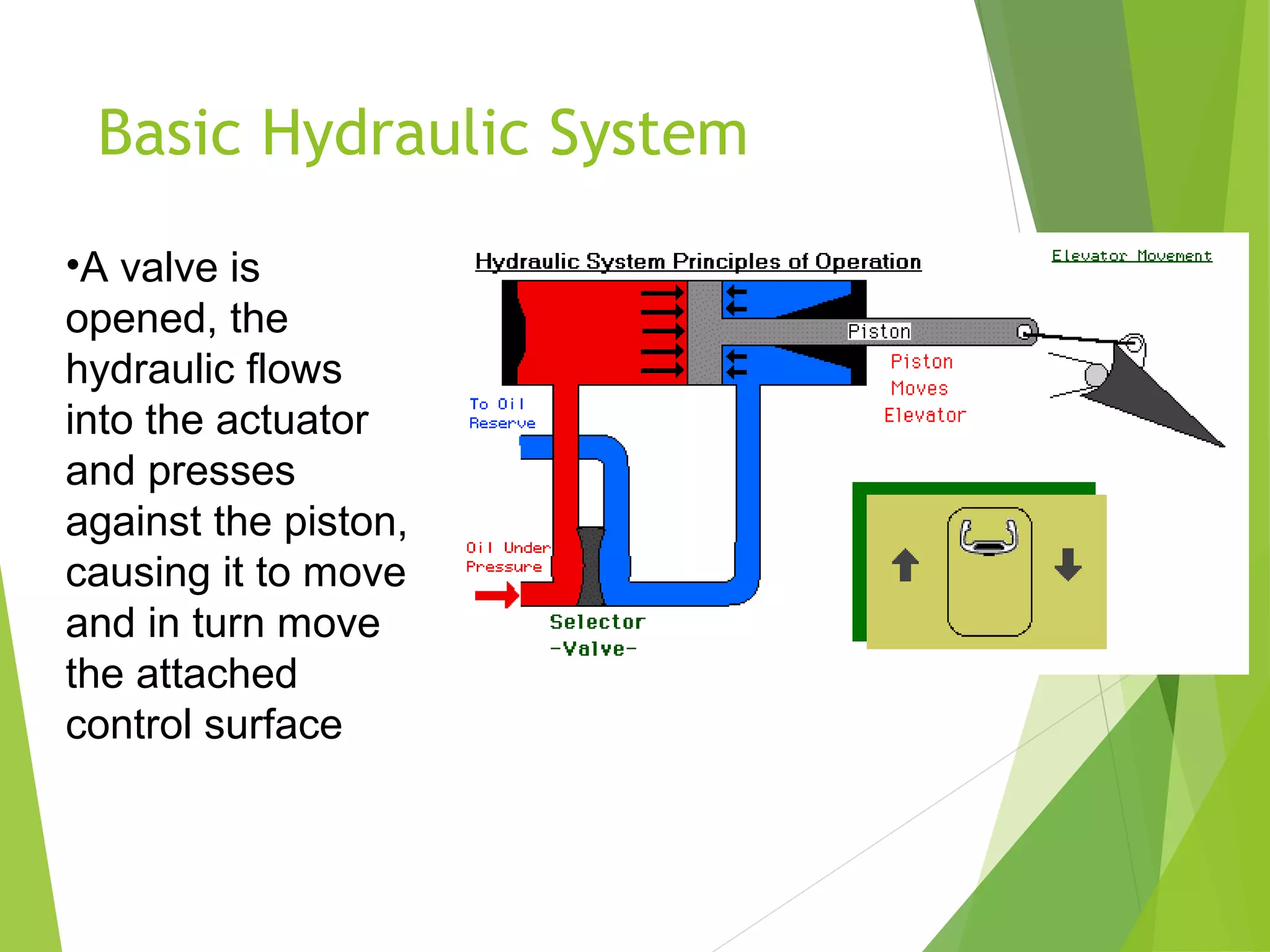

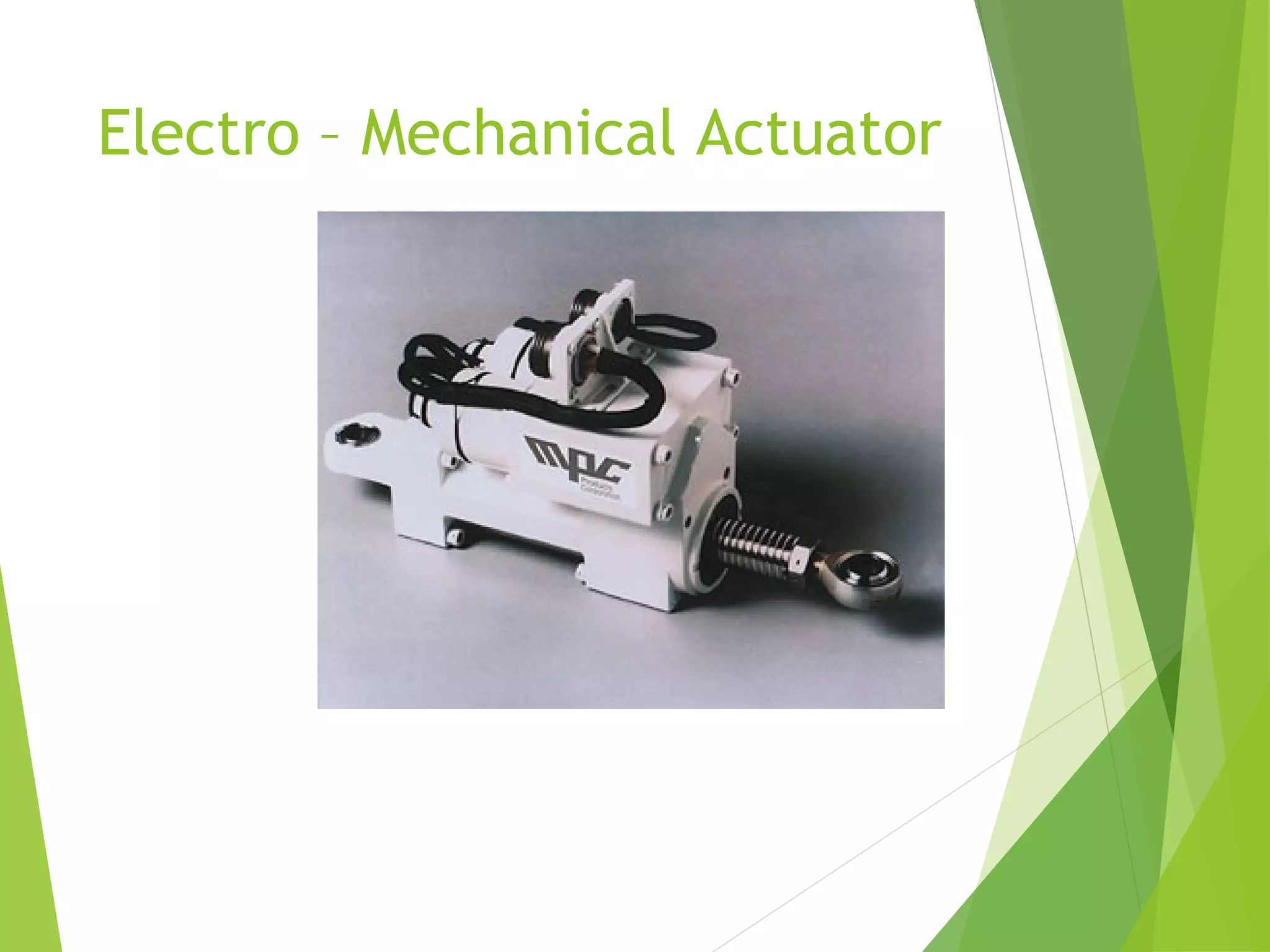

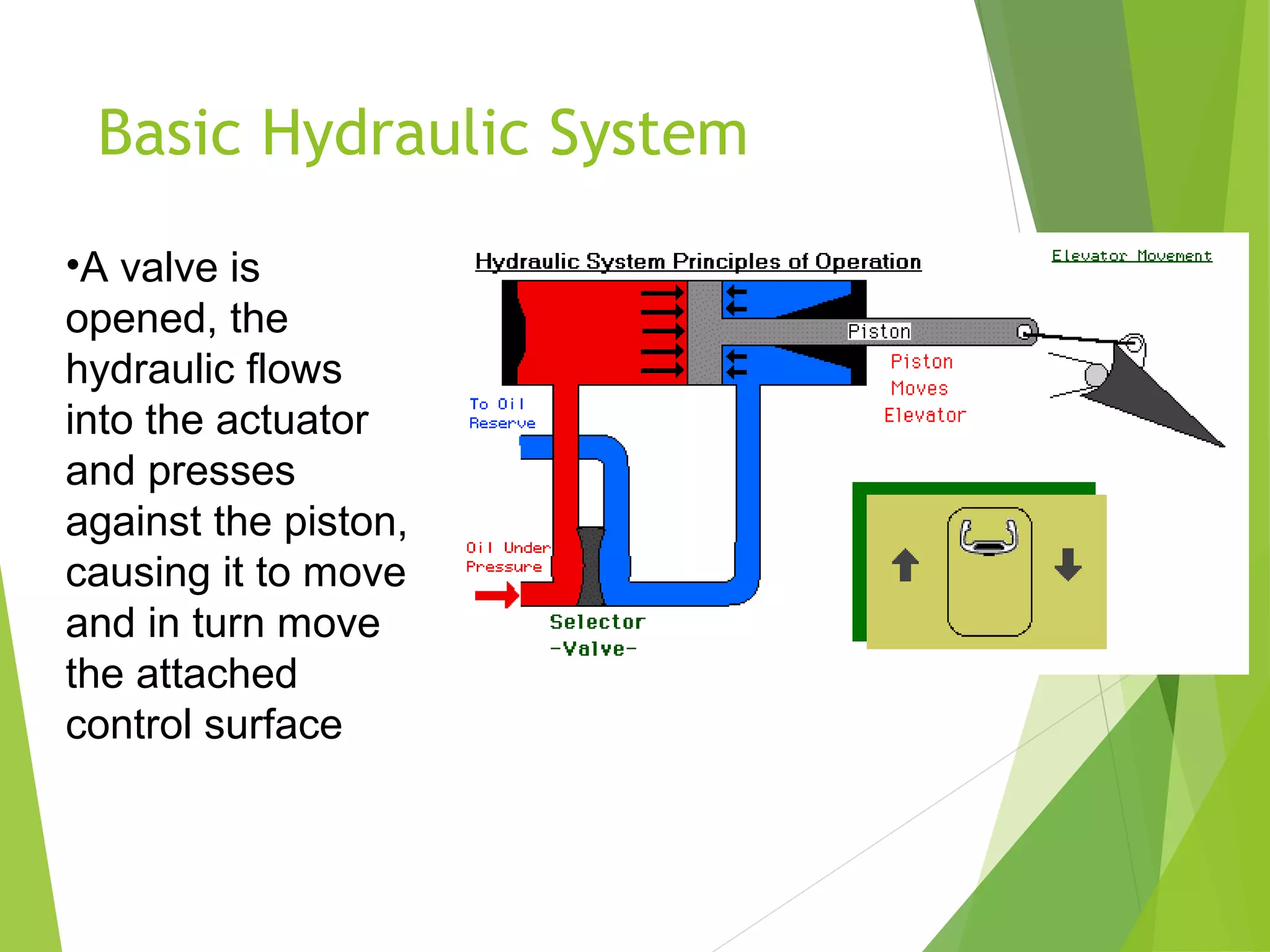

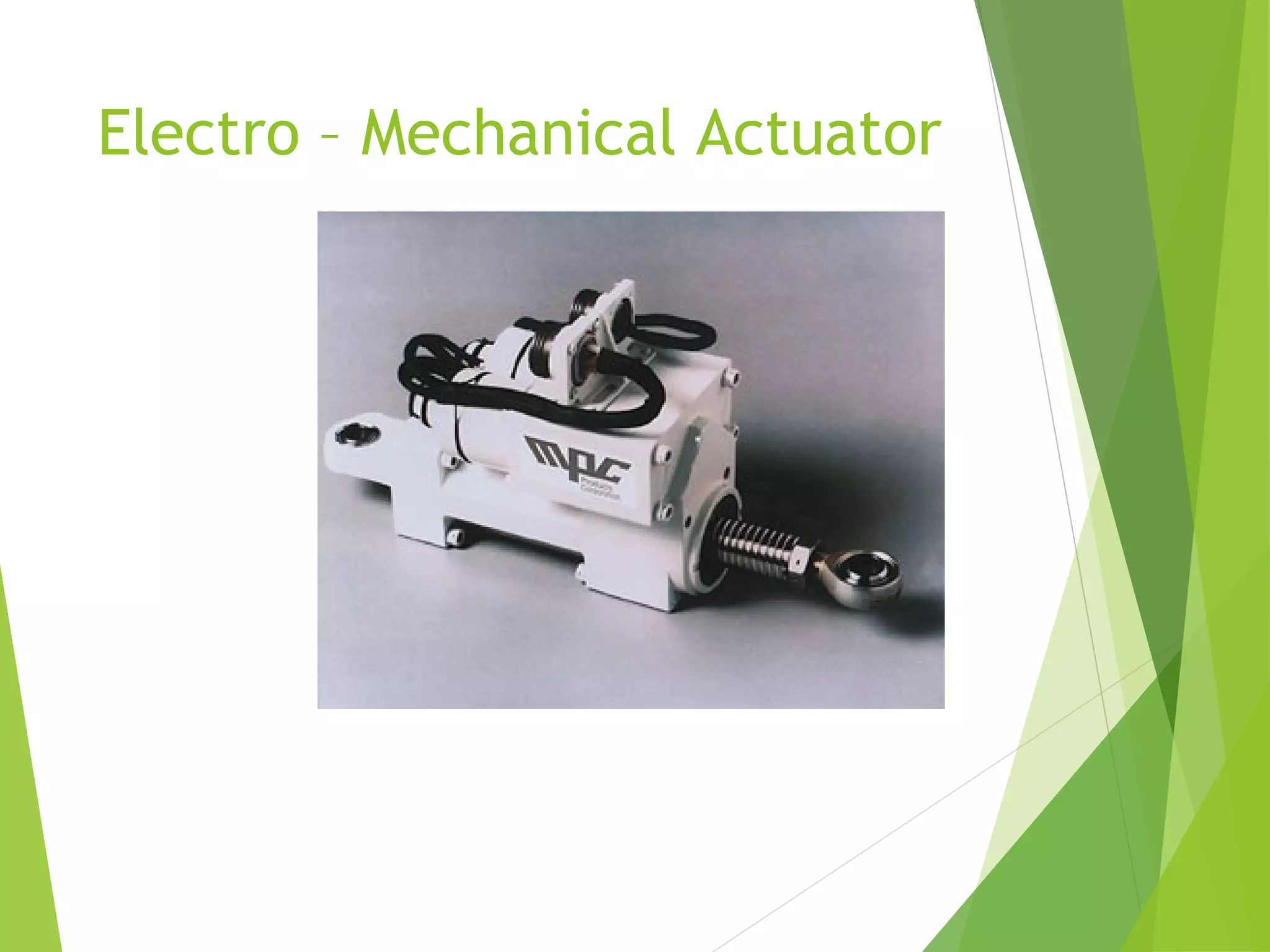

The document discusses aircraft hydraulic systems. It describes how a basic hydraulic system works by using valves and pistons to move control surfaces. It then notes that hydraulic systems are used for flight control and moving structures like flaps, landing gear, and weapons bays by providing extra force. The document lists common hydraulic fluid specifications and pressure ranges. It identifies problems with hydraulic systems like their weight, maintenance costs, and space requirements. Finally, it discusses potential improvements like electric actuators and electro-mechanical actuators that could address these issues.