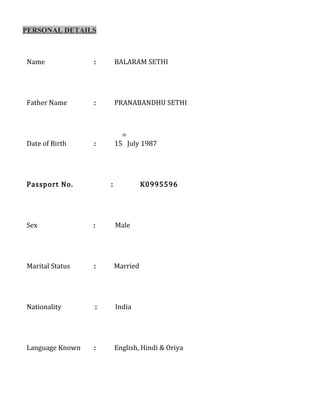

The document contains contact and personal details for Balaram Sethi, including his education, work experience operating slab casters at steel plants in India and Qatar, and responsibilities maintaining casting operations and quality control. It provides his objective of taking on challenging work in technology to learn and lead, and details his qualifications and over 7 years of experience in steel production.