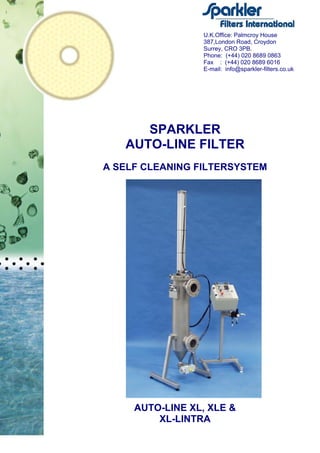

The Sparkler Auto-Line filter is a self-cleaning filtration system designed for continuous operation, employing an asymmetric edge gap element to retain particles. Special models, such as Auto-Line XLE and XL-Lintra, are available to protect against product contamination, particularly for filtering organic solvents and polymers. The filters are constructed from stainless steel, meet pressure vessel regulations, and are complete with automated control features for easy installation.