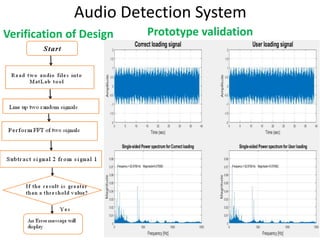

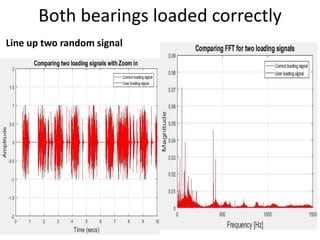

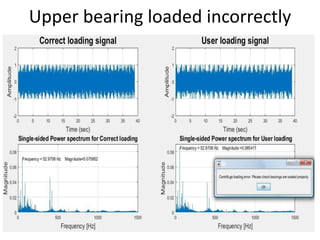

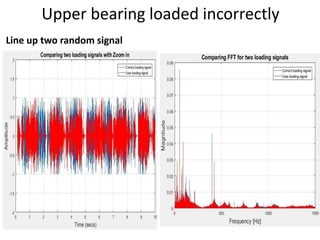

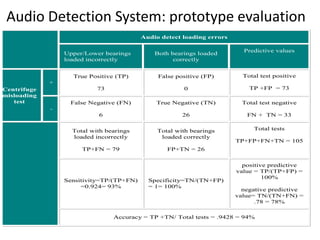

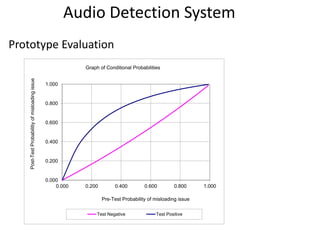

The document summarizes the evaluation of an audio detection system prototype for identifying misloading issues in a centrifuge. Testing showed the prototype had a 93% sensitivity, 100% specificity, and 94% accuracy in detecting when bearings were loaded incorrectly based on analyzing audio signals. Future work is suggested to integrate the prototype with motor control and position sensing to automatically detect and address any misloading issues in the centrifuge.