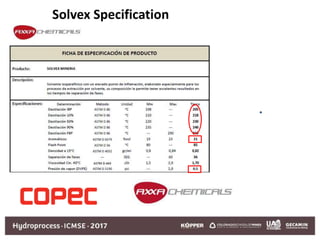

The document discusses the myth that aromatics content significantly impacts evaporation rates in metallurgical grade kerosenes. While aromatics like benzene, toluene, and xylene are commonly associated with higher evaporation, the document finds evaporation is more dependent on initial boiling point. Analysis of Solvex, a metallurgical kerosene, finds its high initial boiling point of 205°C rules out significant benzene, toluene, and xylene content, despite these compounds being aromatic like the copper-oxime extractants. The document concludes aromatics have marginal influence on evaporation rates compared to initial boiling temperature.