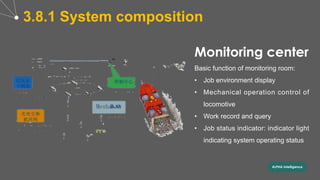

Alpha Industrial Technology Pty Ltd focuses on improving mining safety and efficiency through advanced wireless communication and intelligent solutions. The company has developed various products, such as remote control systems and monitoring technologies, to address challenges in traditional mining practices and enhance safety conditions. Their strategic direction emphasizes digital, green, and intelligent mining to balance productivity with ecological preservation.