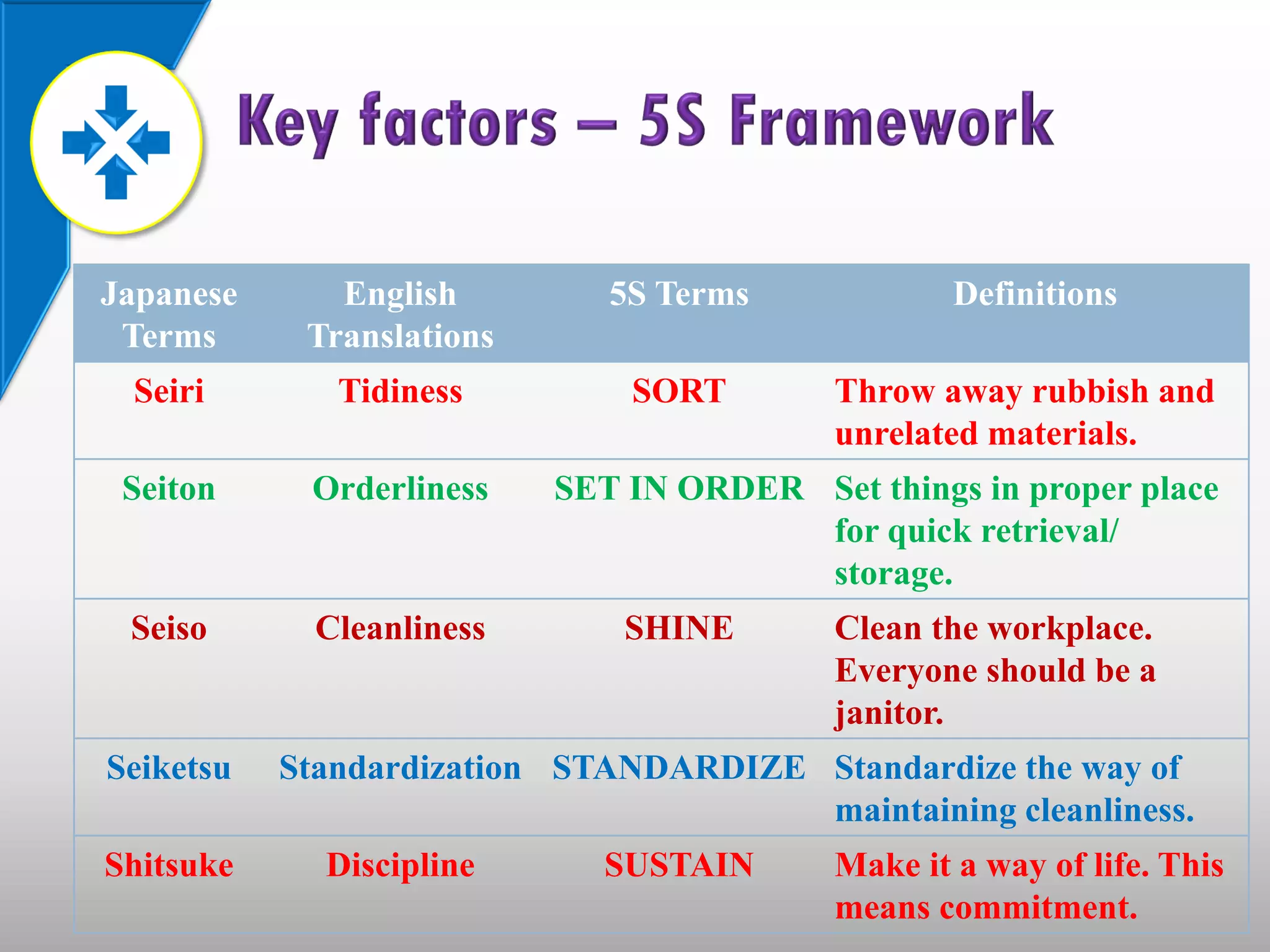

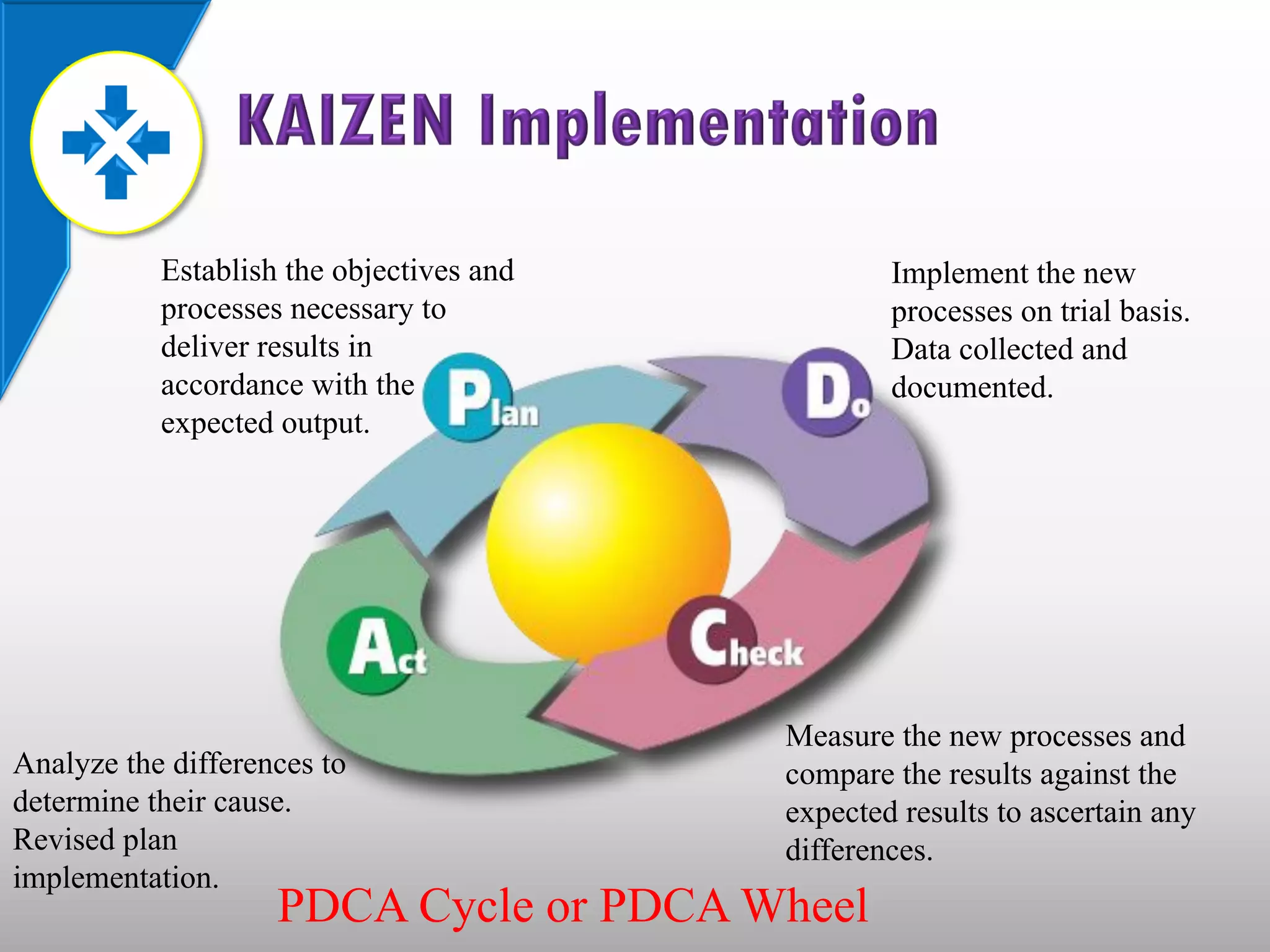

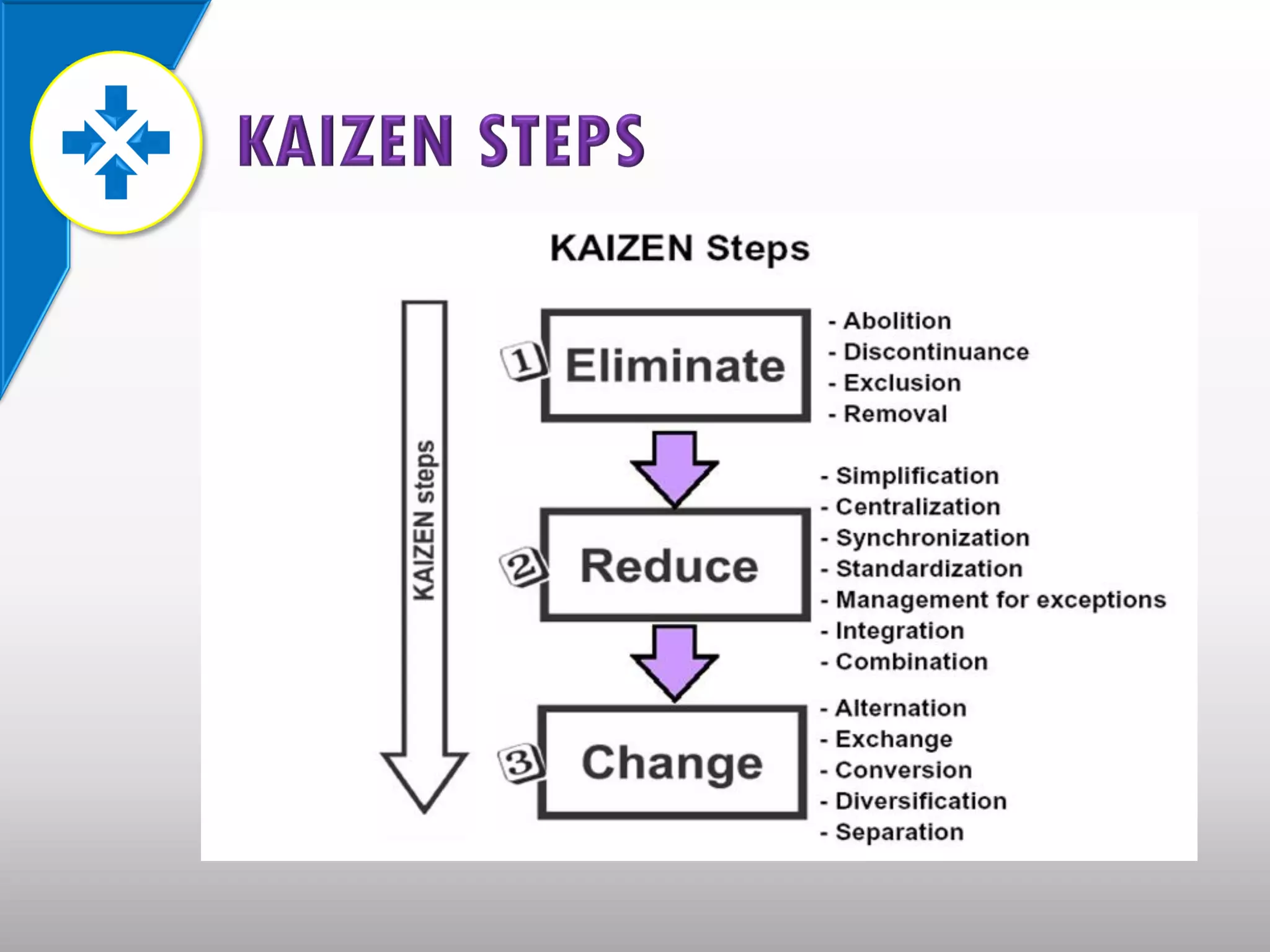

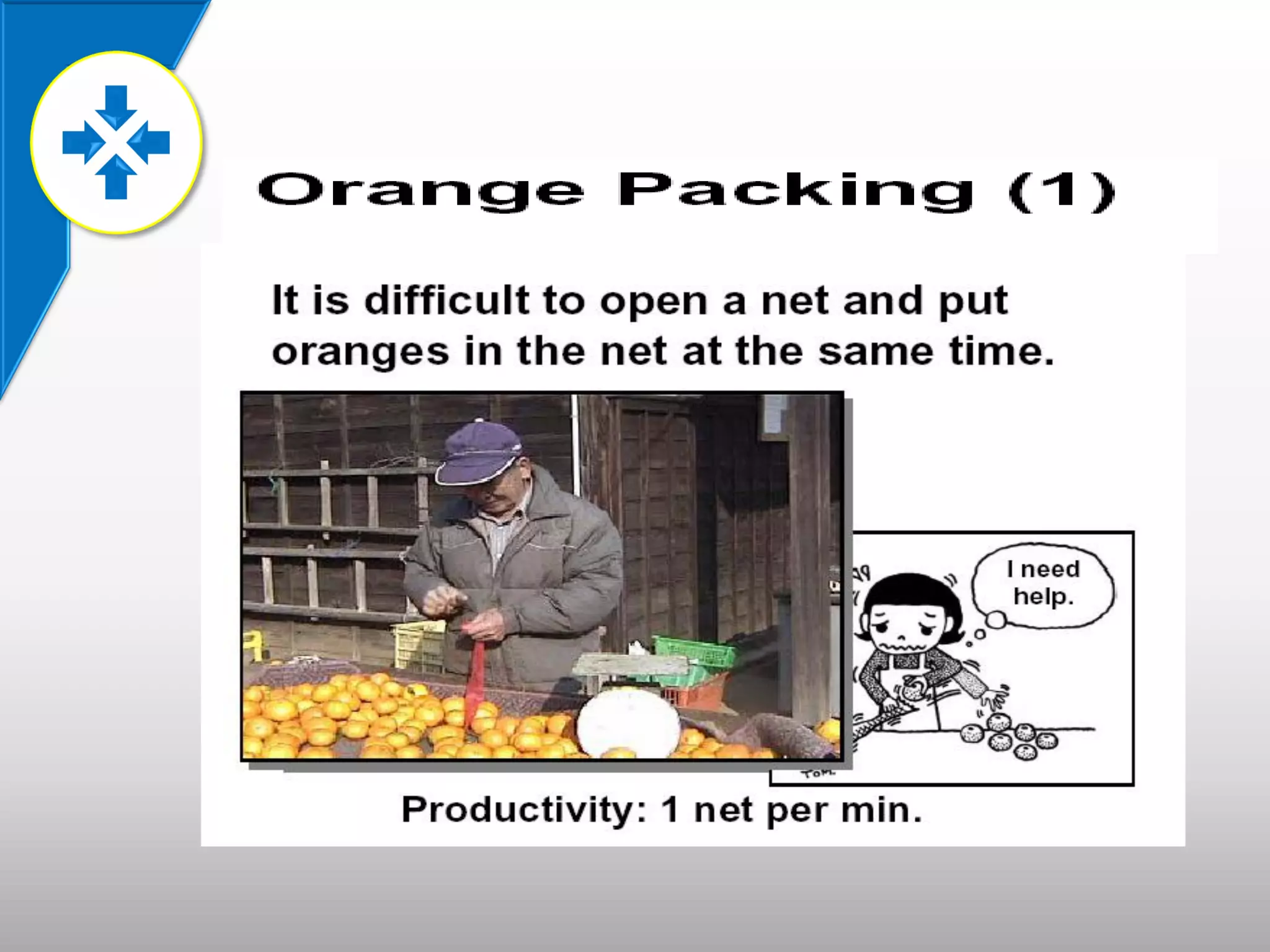

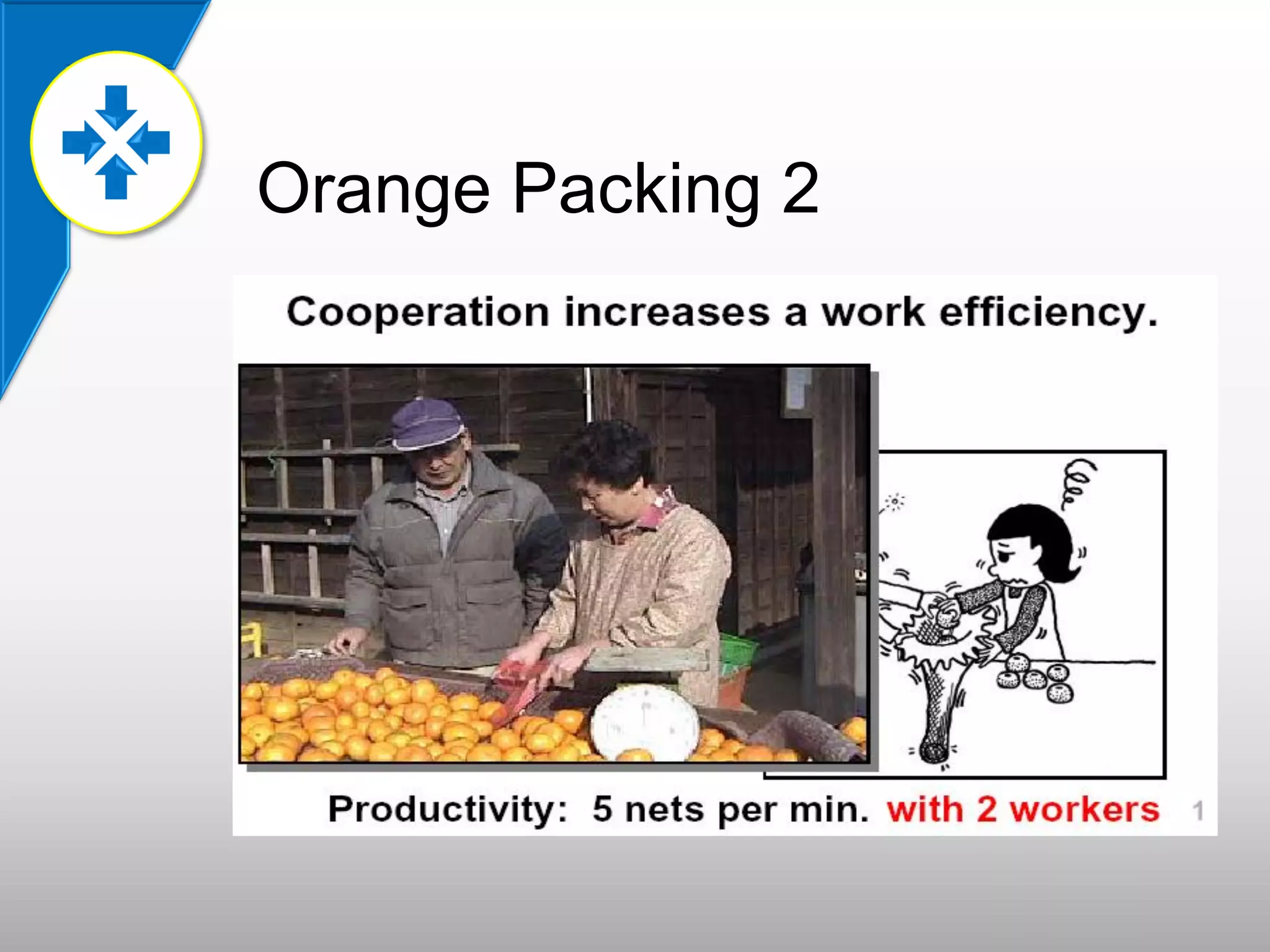

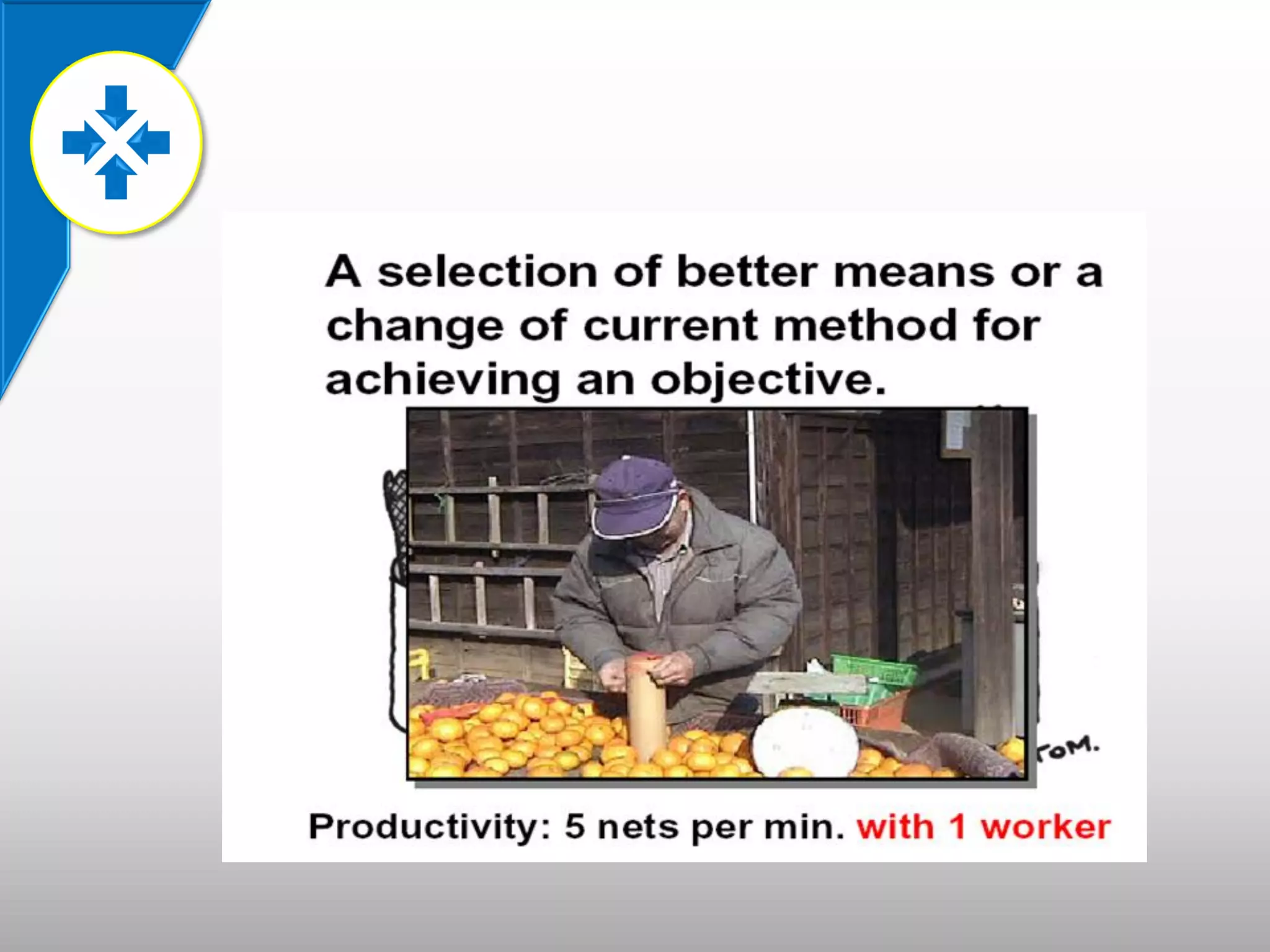

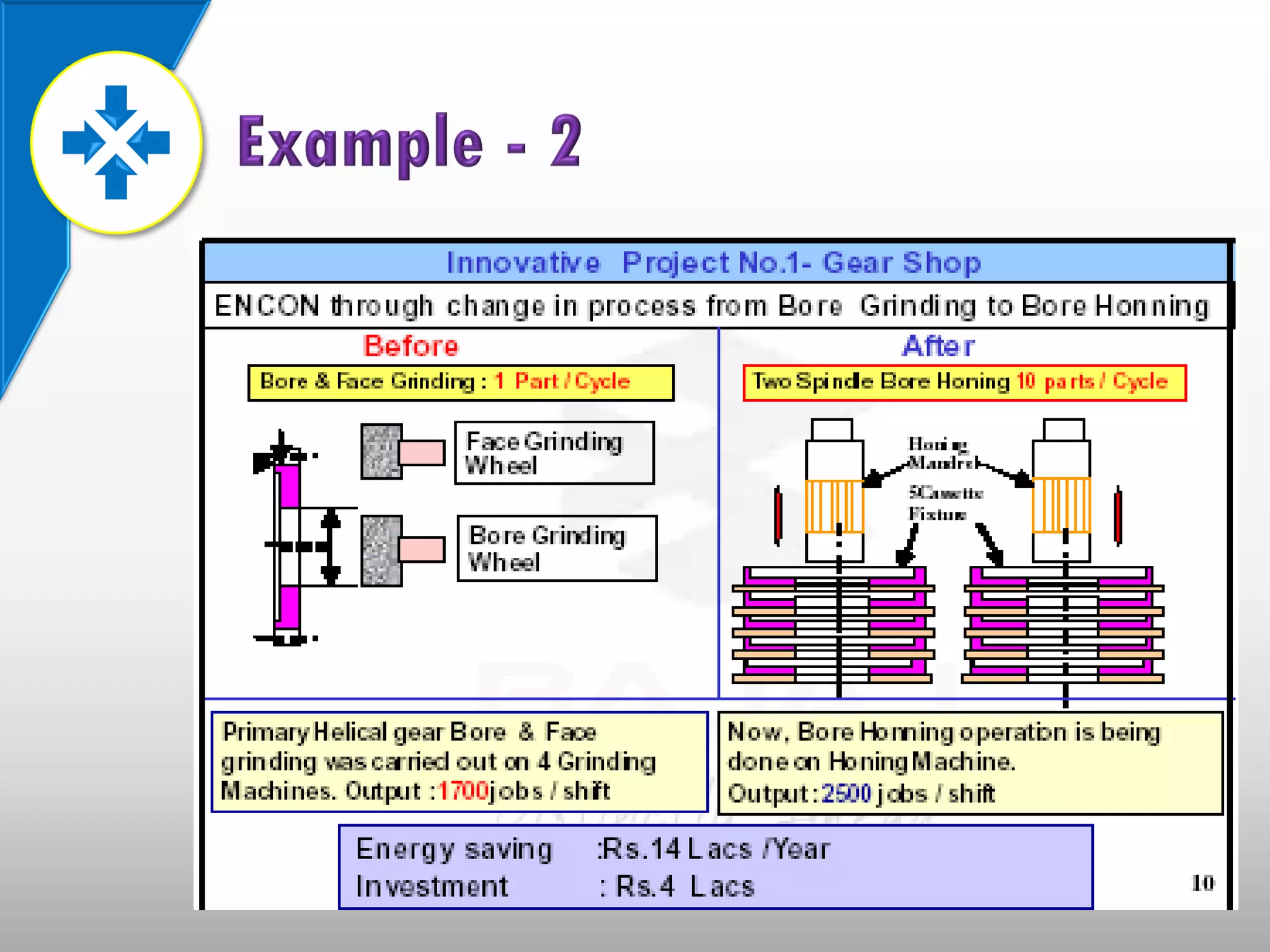

This document discusses process management and continuous process improvement (Kaizen). It provides definitions for key terms like value-added processes, support processes, process control, and process owners. Kaizen is defined as continuous improvement over the long run with minimal resources and participation from all. The five elements of Kaizen and the PDCA cycle for process improvement are also outlined. Examples demonstrate how Kaizen reduced waste and improved space utilization, quality, and employee retention at various companies.