Embed presentation

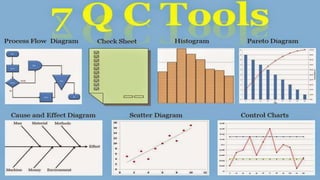

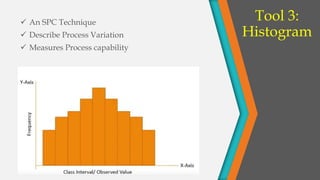

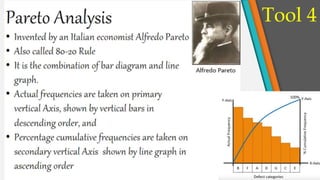

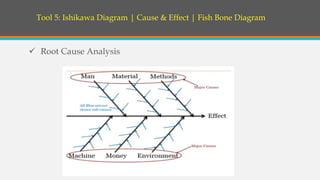

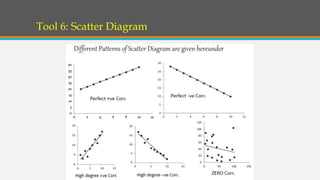

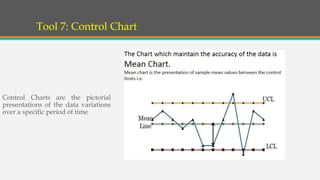

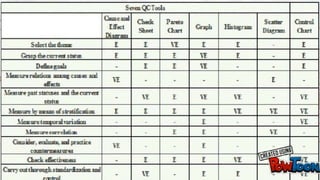

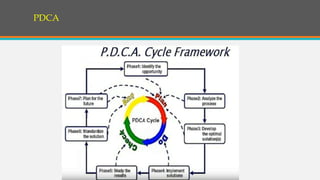

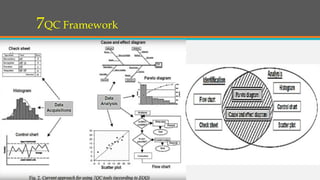

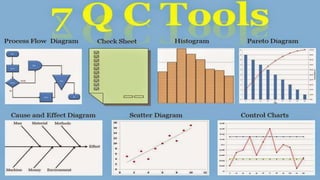

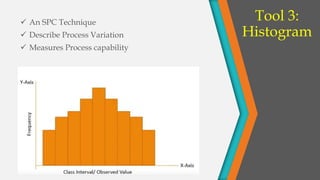

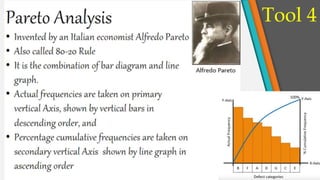

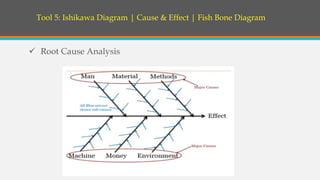

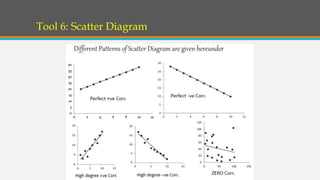

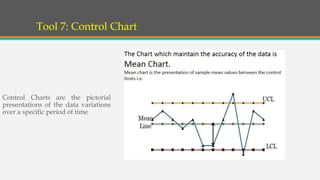

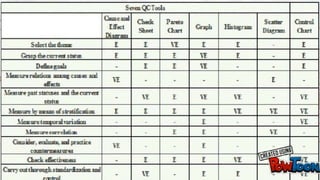

The document discusses the Seven Basic Tools of Quality (7QC), which consist of graphical techniques useful for troubleshooting quality issues, especially for those with limited statistical training. These tools aid in managerial decision-making, data analysis, Six Sigma implementation, and quality improvements. It outlines each tool, including process flow charts, check sheets, histograms, Ishikawa diagrams, scatter diagrams, and control charts.